Medical workers face confusion over which gowns can be reused. Washing the wrong type can ruin protection or create contamination risks. Here, we answer a key question: are surgical gowns washable? This article explains which gowns can safely go through cleaning, how to do it correctly, and tips to keep them effective for longer.

1. Are Surgical Gowns Washable? (Quick Answer)

Only surgical gowns labeled “reusable” or “multiple-use” by the manufacturer can be washed.

Disposable surgical gowns—typically AAMI Level 1–2 using SMS or polypropylene—cannot be washed. Their barrier properties permanently weaken after moisture or laundering.

Reusable surgical gowns are engineered to survive 50–100 industrial laundering and sterilization cycles, depending on the fabric and construction.

Washability Rules at a Glance

Disposable surgical gowns: Not washable; single-use only.

Reusable surgical gowns: Washable with proper industrial processes.

Home laundering: Never allowed; it breaks sterility and violates hospital and regulatory guidelines.

Labeling: FDA requires explicit labeling for reusable surgical gowns.

2. What Makes a Surgical Gown Washable? Understanding Standards

Regulatory Classifications & Requirements

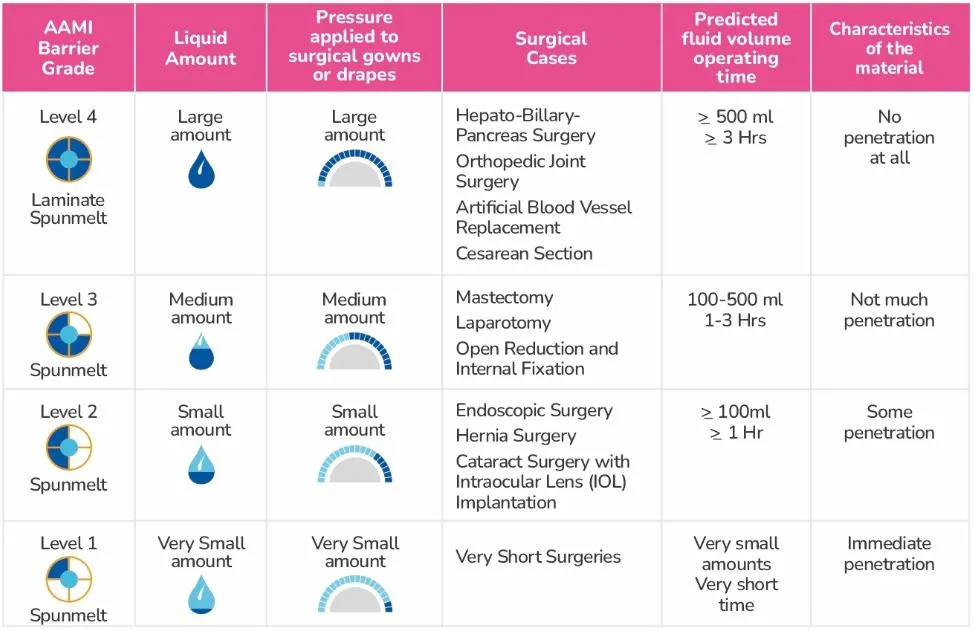

The AAMI PB70 standard classifies gowns by liquid barrier protection:

Level 1 & 2 surgical gowns: Minimal to low liquid barrier protection. These are rarely reusable.

Level 3 & 4 surgical gowns: Designed for higher protection. They feature reinforced seams and specialized fabrics. These gowns can handle multiple industrial wash and sterilize cycles.

Reusable gowns are labeled with their level. Manufacturers test them for performance over their declared lifecycle.

Healthcare Facility Protocols & Inspections

Reusable gowns are:

- Tracked by barcode for their number of uses and cleaning cycles. For example, a Level 4 polyester/cotton gown may have a 75–100 use lifecycle.

- Inspected after each laundering for fabric damage or reduced barrier effectiveness. They are retired when they fail or hit a pre-set max cycle count.

Improper washing or home laundering voids certification. This can lead to regulatory penalties. Hospitals may face loss of accreditation or fines.

Key Points for Hospitals and Users

Gowns labeled “reusable” withstand industrial laundering and maintain protection.

AAMI PB70 Level 1–2: These are disposable. Do not wash them.

AAMI PB70 Level 3–4: Designed for 50–125 professional laundering cycles.

Do not wash surgical gowns at home. This breaks sterility. It voids certification. It exposes hospitals to regulatory risk.

Do not wash surgical gowns at home. This breaks sterility. It voids certification. It exposes hospitals to regulatory risk.

Summary Table: Surgical Gown Washability by Type

| Gown Type | Washable? | Lifespan | Intended Use |

|---|---|---|---|

| Disposable (Level 1–2) | No | Single-use | Single procedure |

| Reusable (Level 3–4) | Yes (labeled) | 50–125 industrial cycles | Multiple procedures |

| Home Washed | No voids sterility | — | Not compliant |

3. Materials Used in Washable Surgical Gowns

Washable surgical gowns use special medical fabrics made for protection, comfort, strength, reuse, and staying the same after many washes.

Polyester – the main material for reusable surgical gowns

High-density woven polyester is the top choice because it lasts a long time, gives off almost no lint (very important in the operating room), shrinks very little, resists chemicals, and handles heat well. It can also get extra treatments like fluid-repellent coatings, germ-killing finishes, and rewetting control.

Polyester-cotton blends

These mixes work well for gowns in lower-fluid-risk surgeries. They feel softer, let air through better, and keep the wearer comfortable with good strength. The downside is that cotton soaks up water, so they are not best for surgeries with lots of fluids.

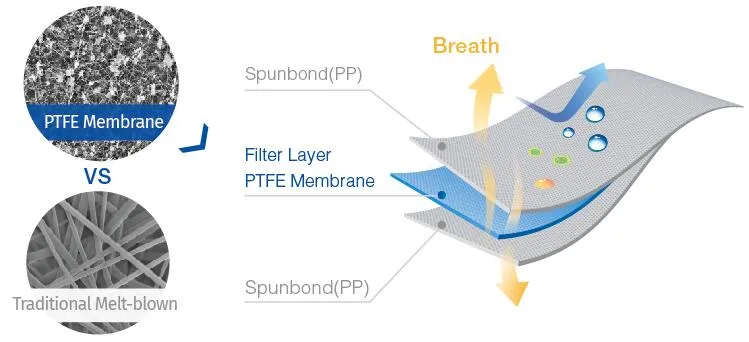

PTFE-laminated composite fabrics

PTFE (a type of plastic membrane) has tiny holes that stop liquids and viruses but let air pass. It gives 99% protection against blood and viral penetration, breathes well, resists chemicals strongly, and lasts a long time. After 50 washes, it keeps 90–95% of its strength and steady water-pressure performance. These fabrics are common in AAMI Level 4 reusable gowns.

ePTFE reinforced fabrics

Expanded PTFE is lighter and stretchier than regular PTFE. It brings more comfort, lets more moisture vapor out (higher MVTR), and feels better for long wear.

Carbon-infused conductive fibers

These fibers cut down static electricity, which matters in operating rooms, when handling tiny electronic surgery tools, or in cleanrooms. They also push germs away with electrostatic repulsion.

4. Engineering Design of Washable Gowns

Modern reusable surgical gowns use PTFE membranes between fabric layers. They also have carbon-infused threads. This design gives better washing performance. It also gives reliable protection through many industrial wash cycles.

PTFE Membranes: Waterproof, Breathable & Virus-Proof

PTFE membranes have tiny pores (0.02–15 μm). We create these by stretching the material in two directions.

The membranes repel water (water contact angle: 110°–140°). This makes the gown waterproof. It also lets air pass through.

These laminates block 99%+ of blood and viruses—even under pressure. I recommend them for infection control.

PTFE laminate has high moisture vapor transmission rates (MVTR). It beats most other waterproof materials. Users stay dry and comfortable during long procedures.

Studies show PTFE-coated gowns keep their barrier strength after 25–50 industrial washes. They last long and support sustainability.

Carbon-Infused Threads: Anti-Static Shield & Microbial Protection

Carbon-infused threads stop static cling. They do this by spreading out electrical charges. This is crucial in sterile environments.

These threads also reduce microbial attachment. They use electrostatic repulsion. This limits microbial growth after repeated washing.

The result? A durable, low-static gown. It maintains safety standards through multiple cleaning cycles.

Mechanical Durability & Testing

ASTM F2407 durability tests check these surgical gowns . PTFE-laminated and high-tenacity spunbond polyester gowns keep over 90% of their original tear strength after 20+ commercial wash cycles.

Electrospun hydrophobic composites (like PU/PTFE) are strong. Tensile strength reaches 10 MPa. Elongation reaches 353%. Perfect for repeated industrial use.

These fabrics handle high temperatures. They handle strong disinfectants. They handle mechanical agitation. Their barrier properties don’t break down.

Lifespan & Value Snapshot

Reusable PTFE surgical gowns keep their barrier, anti-static, and tensile properties over 25–50 industrial wash and sterilization cycles.

Compared to disposables, these gowns reduce clinical waste and per-use costs. Based on my experience, this makes them a smart choice.

Key Features at a Glance:

Waterproof and breathable—better comfort for staff

Over 99% protection against fluids and viruses

ASTM F2407-certified durability and tear strength retention

Carbon threads: anti-static and anti-microbial benefits

Reliable for 25–50 wash cycles without loss of safety or function

5. Disposable vs. Reusable Surgical Gowns: Cost, Performance & Environmental Impact

Hospitals and clinics face a tough choice between disposable and reusable surgical gowns . You need to think about cost, safety, environmental impact, and day-to-day operations. Based on my experience, here’s what the data shows about each option.

Sterility & Workflow

Disposable surgical gowns use polypropylene or SMS fabrics. They arrive pre-sterilized and ready to wear. You get guaranteed sterility straight from the package. I recommend these for busy environments that need quick gown changes and fewer handling steps.

- No laundering needed. No inspection needed. Just toss them after each procedure.

- Great for emergencies or high-volume days. Speed and hygiene matter most here.

Reusable surgical gowns use polyester, polyester-cotton blends, or ePTFE-reinforced fabrics. After each use, you must launder, sterilize, and inspect them before the next patient.

- Hospitals need staff and equipment for cleaning and safety checks.

- Sterility happens after proper reprocessing.

Cost Breakdown

Reusable surgical gowns cost more upfront. But the cost per use drops fast with each wash cycle.

| Surgical Gown Type | Cost Per Use | Notes |

|---|---|---|

| Reusable Surgical Gowns | ~$0.80 | After 75 cycles |

| Disposable Surgical Gowns | $4–$6 | No savings over time |

Example:

A 500-bed hospital switches to reusable surgical gowns. They save thousands per year on gown costs.

Protective Performance & Lifespan

Disposable surgical gowns offer one-time protection. Most provide AAMI Level 1–2 for low fluid exposure.

Reusable surgical gowns deliver AAMI Level 3 protection through 75–100 industrial wash and sterilization cycles.

Over 90% protection properties stay intact after 50 cycles.

Tensile strength after 75 cycles stays high (82.30–116.55 lbf).

I find them reliable for most surgical and procedural needs.

Environmental Impact

EPA data shows reusable surgical gowns cut medical waste by 1.2 tons per year in a 500-bed hospital.

Overall savings on resources:

– 64% less energy

– 66% fewer greenhouse gases

– 83% less water

– 84% less solid waste compared to disposables

At-a-Glance Comparison

| Feature | Disposable | Reusable |

|---|---|---|

| Sterility out of the package | Guaranteed | Must be verified after processing |

| Reprocessing labor | None | Required (launder, inspect) |

| Per-use cost | $4–$6 | $0.80 (after 75 uses) |

| Environmental impact | Higher landfill waste | Reduces waste and resource use |

| Usable lifespan | One-time | 75–100 cycles |

| Material | Polypropylene, SMS | Polyester, ePTFE , reinforced blends |

| Fluid protection (multi-use) | No | Yes (AAMI Level 3, strong retention) |

Quick Takeaway

For high-turnover settings, I suggest disposables. They offer convenience and infection control. For hospitals focused on cost savings and sustainability, I recommend reusable gowns. They provide strong protection, last longer, and help the environment. Making the switch to reusable gowns cuts operating costs and reduces your environmental footprint. Safety stays strong.

6. How to Wash Reusable Gowns (Step-by-Step)

Reusable surgical gowns need strict cleaning protocols. This preserves their barrier protection. It also extends their usable lifespan. Here’s a method I recommend based on proven procedures and best practices.

Step 1: Pre-Treat Blood and Protein Contaminants

Start by rinsing any visible blood with water below 120°F (I suggest 100°F) for several minutes.

Add 2 oz/cwt alkali if possible to assist stain removal. Avoid hotter water to prevent setting blood stains.

An enzymatic soak at 100°F for 15 minutes helps tackle protein-based soils.

Blood dissolves better close to 120°F. So a warm rinse works faster and better than cold.

Prevent over-wetting to reduce fabric wear during pre-treatment.

Step 2: Thorough Machine Washing for Decontamination

Sort surgical gowns away from cotton or lint-producing textiles. This maintains the integrity of the barrier fabric.

Load washing machines to no more than 70%–75% capacity. Underloading by 25% improves cleaning. This matters a lot for lightweight barrier materials.

For a typical 100 lb washer, I recommend this wash cycle:

- Break: 8 minutes at 150°F

- Bleach/Detergent: 8 minutes at 165°F, using 4–5 oz/cwt alkali and 3–4 oz/cwt detergent

- Rinses: Three cycles, each 2 minutes long, at lower temperatures (150°F, 135°F, and 120°F)

- Final Sour: 5 minutes at 100°F, using 1 oz/cwt souring agent to adjust final pH to 6–8

Use mild alkali and low-alkaline detergents to help preserve fabric barrier qualities.

For oil stains, include solvents in the initial rinse below 120°F if required.

Employ at least seven rinse-and-drain cycles to dilute and remove contaminants. This achieves an over 90% reduction in microbial load.

Rinse well. Barrier fabrics do not retain surfactants, but complete removal is essential.

Step 3: Extraction, Drying, and Sterilization

Extract at up to 400G (centrifugal force) for best moisture removal. Avoid hydraulic extractors as they can stretch or deform barrier fabrics.

Tumble dry at a maximum of 140°F. Avoid too much heat to protect the gown’s shape, strength, and fluid resistance.

After drying, steam- sterilize gowns for surgical use . Standard parameters are 270°F for four minutes. This aligns with CDC and hospital protocols.

Many facilities include autoclaving as an extra sterilization step. This matters for gowns used in a sterile field.

Quality Control, Compliance, and Inspection After Each Cycle

Inspect every gown for damage or barrier compromise after laundering. Undamaged gowns should return to circulation.

Gowns with tears, too much wear, or holes must be retired right away. This maintains sterility and safety.

Special detergents may be required for oil-based stains. Microfiber or laminate barrier gowns are more susceptible.

Additional Recommendations

- Add bleach with care. Follow fabric manufacturers’ directions to avoid weakening the material.

- Adjust all cleaning agents to suit the textile’s composition. Follow the manufacturer’s care recommendations.

Reusable surgical gowns maintain their protective function and clinical value if you process them under these strict conditions. These routines, when applied well, deliver over 90% reduction of microbial load. They protect against punctures. They ensure continued fluid resistance for every patient.

7. RFID Tracking and Hygiene Assurance in Reusable Surgical Gowns

Hospitals now use RFID tracking to manage reusable surgical gowns. This gives them better accuracy, visibility, and compliance.

RFID Technology: Inventory Control & Lifecycle Management

Every surgical gown gets a unique, washable RFID tag. You can track it in real-time through storage, use, laundering, and retirement.

Top facilities, like United Hospital Services, manage over 250,000 gowns this way. They process 20,000 RFID-tagged gowns each day.

Loss rates drop: RFID brings linen loss rates down from 15% (manual tracking) to less than 3%.

RFID systems send alerts when gowns are near their recommended laundry cycle limit. This ensures retirement happens on time and keeps compliance strong.

I recommend this tech because it enables hands-off inventory counts and audit-ready documentation. Hospital staff do less manual work.

Infection Control: ATP Monitoring & Regulatory Compliance

Hospitals use ATP hygiene monitoring in laundry processes. Over 95% of gowns pass hygiene thresholds when staff follow protocols.

Facilities log sterilization and cleaning results with RFID. This keeps a verifiable record for audits and regulatory checks.

ATP testing detects contamination fast. Combined with RFID data, it ensures compliance with infection control standards.

Chemical Damage Prevention & Barrier Longevity

Neutral oxidizing agents (like hydrogen peroxide) work better than harsh chlorine bleach. They protect fabric strength and barrier function.

RFID logs chemical exposure and physical testing results. Staff get alerts if gowns show early wear or barrier failure.

Most gowns endure 75–150 washes. Based on my experience, I suggest using RFID to enforce these cycle limits. It keeps performance high and cuts costs.

8. Inventory Management, Maintenance, and Audit Protocols for Washable Surgical Gowns

I recommend strong inventory and maintenance strategies for reusable washable surgical gowns. These protocols impact gown life, compliance, and cost control.

Barcode Tracking and Gown Lifecycle Monitoring

Barcode scanning tracks each surgical gown’s laundering and use cycles. This ensures no gown exceeds its service life. It helps prevent barrier failures.

Facilities using barcode systems report:

- Better compliance with retirement guidelines

- Less gown loss and missing inventory

- Accurate data on gown lifespan (40–75 washes per reusable gown, depending on materials and clinical usage)

Automated alerts based on barcode data prompt staff when gowns approach their maximum cycles. This ensures on-time retirement.

Safety Audits: Fluorescence Marker Testing

I suggest conducting fluorescence marker audits every quarter by:

- Applying a harmless fluorescent agent to gown surfaces before laundering

- Using UV light to check for leaks or breaches after cleaning

This method reveals tiny barrier defects invisible to the eye. Compromised gowns are retired before use.

Studies show these audits prevent hidden failures. They ensure compliance and quality.

Stock Rotation and Cost Control: FIFO System

Use FIFO (First-In, First-Out) rotation for all surgical gown inventories.

Benefits include:

Even wear across the stock

Fewer cases of unexpected, expensive bulk replacements from overused gowns

Up to 15% lower annual spending by reducing premature retirements

More Proven Maintenance Strategies

Regular seam inspections with magnification catch signs of fraying or separation. This maintains FDA-required barrier performance.

Material compatibility logs record fabric type (e.g., SMS, reinforced polyester) and proper cleaning agents. This avoids chemical damage.

Failure and retirement documentation lists reasons—strike-through, loss of water resistance—to inform future buying and maintenance updates.

Impact and Outcomes

Example: A medium-sized hospital adopted barcode tracking and regular marker audits. It saw a 22% reduction in unexpected gown retirements. Average usable gown lifespan increased 17% within two years.

Based on my experience, strict maintenance protocols sustain AAMI Level 3/4 barrier performance for at least 50 cycles per gown. Post-laundering strike-through testing verifies this.

9. Common Questions About Washable Surgical Gowns: Shrinkage, Sterilization, and Durability

Reusable surgical gowns can handle repeated washing, sterilization, and long-term use. I’ll answer the most common concerns about their performance, durability, and infection control.

Do Surgical Gowns Shrink After Washing?

Reusable surgical gowns made from polyester and cotton blends perform well in shrinkage tests:

– Less than 3.6% shrinkage after 75 industrial launderings

– Brand/level data after 75 washes:

– Brand A, AAMI Level 2: 2.41%

– Brand A, Level 3: 1.60%

– Brand B, Level 2: 2.30%

– Brand B, Level 3: 3.59%

Most brands stay below the 3% maximum shrinkage tolerance set by ASTM standards for medical apparel. This stays true even after extensive use. Gowns keep their fit and protective coverage because of this stability.

Colorfastness: Standard AATCC tests show most reusable gowns maintain a gray scale rating above 4 after 75 washes. This means no visible color change.

Pilling resistance: Remains high. Gowns look and feel new.

Can Level 4 Reusable Gowns Survive Chemical Sterilization?

Yes. Level 4 reusable surgical gowns can handle peracetic acid and other chemical sterilization methods. Based on my research:

– Gowns keep their seam strength and barrier integrity after repeated cycles.

– After 75 washes with sterilization, there is no major tear strength or barrier loss.

Studies and guidelines confirm that fabric protection and performance standards stay intact with approved chemical disinfection. This makes them suitable for high-risk procedures and tough sterilization schedules.

What Temperature Kills C. diff on Surgical Fabrics?

For effective disinfection against pathogens like Clostridioides difficile, I recommend:

– Minimum washing temperature: 71°C (160°F)

– Hold time: At least 30 minutes

The CDC and hospital standards cite this protocol. It ensures C. diff spores are killed on reusable medical textiles, including surgical gowns.