Dirty footprints on clean floors cause stress at homes, clinics, and job sites. Cleaning again wastes time and money. This guide explains what shoe covers are, how they work, and when they make sense. You will learn why shoe covers protect floors, improve hygiene, and solve common daily problems fast.

What Are Shoe Covers? Definition and Core Purpose

Shoe covers are lightweight, disposable barriers you wear over regular shoes. They block dirt, germs, and liquids from spreading between areas. People also call them booties, overshoes, or boot covers. These single-use items work as personal protective equipment (PPE). They create a shield around your shoes.

Why You Need Shoe Covers: 3 Key Benefits

1. Contamination Control

Shoe covers stop germs, bacteria, and harmful microbes from entering clean spaces. Healthcare facilities, labs, cleanrooms, and food plants depend on this barrier. It cuts down cross-contamination risk. Your shoes pick up thousands of germs from parking lots, restrooms, and outdoor areas. Shoe covers block them at the door.

2. Floor Protection

These covers shield expensive floors from dirt, scuffs, debris, and tracked-in mess. Construction, remodeling, or maintenance work can damage surfaces. Think of shoe covers as insurance for new hardwood, polished marble, or fresh tile. They keep facilities clean without endless sweeping or mopping.

3. Shoe Protection

Shoe covers protect your footwear from fluids, chemical spills, stains, and damage. Lab workers handle harsh chemicals. Workers in wet areas face constant moisture. This splash-resistant layer keeps shoes dry and safe.

Most disposable shoe covers come with elastic ankle bands for a snug fit. You get non-slip soles with textured grips for traction. The one-size-fits-most design works with sneakers, dress shoes, and work boots.

Types of Shoe Covers: Disposable vs Reusable Options

Disposable or reusable? This choice affects your costs, maintenance work, and environmental impact for years. Each type fits different needs. Know the materials, prices, and how long they last. This helps you pick the right option.

Disposable Shoe Covers: Materials and Cost Breakdown

PE plastic (polyethylene) leads the disposable market with a 41.9% global market share in 2025. It stops liquids and bacteria from getting through. The light, flexible design resists tears during repeated use. Non-woven fabric and paper versions exist. They block moisture less.

Prices change based on thickness and medical-grade certification:

- Budget tier: $0.05–$0.20 per pair in bulk packages (50–100 pairs)

- Standard tier: $0.43 per pair (example: 150-pair boxes at $65 total)

- Premium medical-grade: Up to $0.50 per pair for reinforced PE with germ-fighting treatment

Hospital surgical rooms use disposable options. So do food processing plants, labs, and livestock facilities. These places need zero cross-contamination risk. They also need fast replacement. Schools, offices, and trade shows with lots of visitors like the no-cleaning benefit. Medical supply distributors sell them. So do industrial safety vendors and online stores. Bulk packs come in 50–150 pairs.

Reusable Shoe Covers: Durability and Long-Term Value

Neoprene, rubber, silicone, and nylon last hundreds of uses. One pair of neoprene boot covers lasts a contractor four months of daily jobsite work. That equals about 150 disposable pairs in the same time.

Rubber medical-grade shoe covers survive many wash cycles. The material doesn’t break down. The flexible, tear-resistant build stays protective after repeated cleaning and disinfection.

Cost comparison shows long-term savings:

- Reusable : $19.99–$29.99 per pair upfront

- Disposable equivalent (150 pairs at $0.43 each): $64.50 over four months

You break even after about 50–70 uses. But reusable options need work. You must wash, disinfect, and dry covers after every use. Skip proper cleaning? You lose the hygiene benefit. Facilities without cleaning systems or time lose this edge.

Construction teams get the most value from reusable covers. So do real estate agents and homeowners with steady foot traffic. Medical and food safety places use disposables. They must meet strict rules.

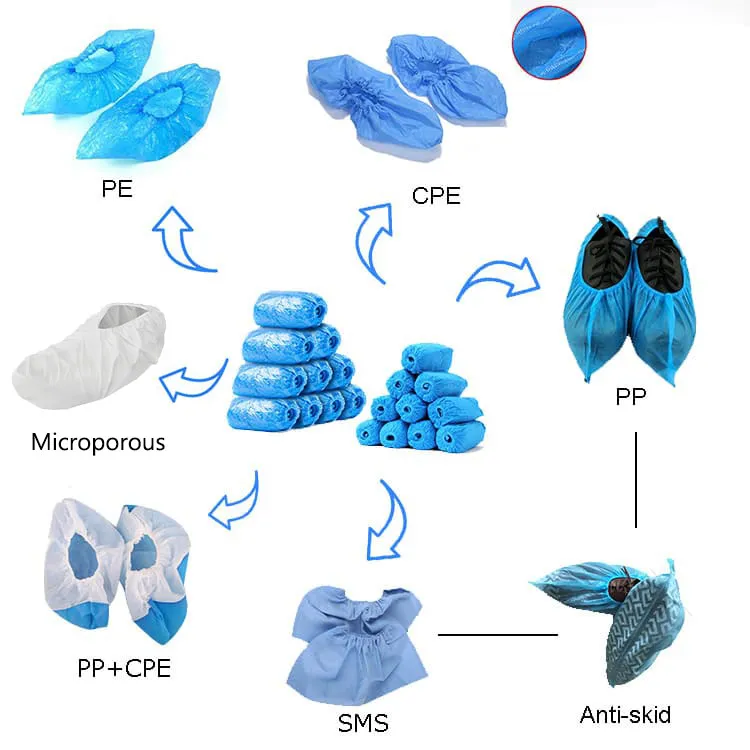

Shoe Covers Materials Guide: Which Material for Your Needs?

Pick the right material. Your shoe covers will protect floors and block contaminants. Pick the wrong one? You waste money on slippery covers that tear. Floors still get damaged.

Different materials solve different problems. Some stop the water. Others breathe better or grip surfaces. Your choice matters.

Polypropylene (PP): The Breathable Medical Standard

PP spunbonded fabric brings the comfort that medical facilities need. This 100% virgin non-linting material feels soft against shoes. Nothing like stiff PE plastic. Each pair weighs less than bulky rubber options (which hit 1 pound per pair). You can clean and reuse PP shoe covers many times. Protection stays strong.

GMP-certified facilities rely on PP for sterile area transitions. The latex-free and silicone-free mix meets pharmaceutical and lab needs. Workers move between clean and unclean zones without risk. The breathable design stops sweat buildup during long wear. No breathability data exists in MVTR (moisture vapor transmission rate) terms. But medical use proves it works.

Waterproof Materials: PE, CPE, and PCPP Compared

Liquid protection needs differ by job. PE ( polyethylene ) dominates with 37.2% market share in 2025. The non-porous surface blocks water. HDPE costs less than the LDPE versions. Both handle washing and autoclaving for reuse. But smooth PE surfaces slip easily. Anti-skid ratings stay low.

CPE (chlorinated polyethylene) fixes the grip issue. This 65% LDPE and 35% LLDPE blend adds textured traction. The seamless barrier stops liquids better than basic PE. You get high anti-skid performance on wet tile, concrete, and epoxy floors. CPE offers good value for dirt and liquid protection.

PCPP (polyethylene-coated polypropylene) tops the premium waterproof shoe covers . The coating resists peeling through heavy use. XtraGrip premium tack technology gives you very high anti-skid ratings in wet and dry spots. Low-linting features work well in cleanrooms. Construction crews in mud or hospitals with spills benefit most.

Premium Filtration: SMS and Tyvek for Maximum Protection

Tyvek’s flash-spun process builds a barrier against particles, microorganisms, and light liquids. Tyvek IsoClean versions meet cleanroom and pharmaceutical standards. Bound and serged seams stop contamination leaks. CE-Force I5 covers use special fabric balancing for GMP spaces.

Prices match protection levels: Basic PE costs $0.05–$0.20 per pair. Premium SMS and Tyvek range from $0.30 to $2.00 per pair. Labs handling biohazards need this protection. So do semiconductor facilities where single particles ruin million-dollar batches.

Grip Technology: PVC Texture Soles for Wet Environments

PVC textured soles with SureGrip, UltraGrip, or SafeStep coatings give you high friction. The super sticky polyethylene and nonwoven coating mix grips wet tile, coated concrete, and epoxy surfaces. Seamless bottoms boost performance by cutting out weak spots.

Wet floor tests prove the non-skid power in real use. Rough surfaces don’t wear through the coating. Hospitals, commercial kitchens, and manufacturing plants with constant moisture need this grip. Standard smooth covers fail here.

How to Choose the Right Shoe Covers?

Wrong shoe covers waste money and create safety hazards. Match your choice to your work area. Otherwise, you’ll face slips, tears, and contamination. Three key factors matter: material type, proper fit, and price.

Material Selection by Use Scenario

Your work area decides which material you need. Non-woven PP (polypropylene) works great for homes at $0.05–$0.15 per pair in bulk. This breathable, light material handles everyday visitors and light cleaning. One-size-fits-most versions fit US shoe sizes 5–11 (foot length 22–30 cm).

Medical and healthcare settings need lint-free, water-resistant barriers. PP or PE (polyethylene) options cost $0.10–$0.30 per pair. Labs need stronger chemical resistance. Pick CPE (chlorinated polyethylene) versions for those areas. These materials drop fewer particles in clean zones.

Industrial areas need heavy-duty protection. CPE, PCPP, or PVC-soled covers range from $0.20–$0.50 per pair. Look for tear strength above 20N. Check abrasion resistance over 400 cycles (ISO 20344 standard). Wet floors need PVC waffle-textured soles with friction coefficients above 0.4. These meet SRC slip resistance standards. SRA tests the ceramic with detergent. SRB tests steel with glycerine.

Anti-Slip and Waterproof Standards

EN ISO 20345/46 certifications verify waterproof performance. The WRU rating tests water penetration through the top. Quality shoecovers allow less than 0.2% absorption after 60 minutes in water. Construction crews in mud need this. Medical staff facing spills need it too.

Slip resistance ratings stop falls. SRA, SRB, and SRC classifications show tested grip. SRC-rated covers pass both ceramic and steel surface tests. Industrial sites with wet conditions see fall incidents drop 70% with proper PVC-soled covers. Standard smooth covers keep coefficients below 0.3. That’s a 40% higher fall risk.

Sizing and Closure Systems

One-size-fits-most designs work for US men’s 5–12 / women’s 6–13 (EU 35–47). Actual coverage handles 22–30 cm foot lengths. Shoes larger than US size 12 cause slippage. This doubles trip hazards. Tight fits on sizes below US 5 tear after one use.

Elastic bands stretch 200–300% for quick use. They grip odd shoe shapes well. But overstretching tears the material. Tie bands adjust better for big footwear. They support 5–10 reuses but take longer to put on. Elastic versions cost 10% more than tie closures.

Cost Analysis and Bulk Savings

Calculate single-use cost: divide pack price by quantity. Then add disposal fees. A 100-pack of PP shoe covers at $10 equals $0.10 per pair. Bulk buying cuts this sharply:

- 50 pairs : 10% discount on PP, 15% on CPE

- 100 pairs : 20% discount on PP, 25% on CPE

- 1,000+ pairs : 40–50% discount on PP ($0.03–$0.08 each), 50% on CPE ($0.12 each)

Brand comparisons matter for lasting use. CPE shoe covers from Valutek cost 1.5 times more than generic PP versions. But they last twice as long. Their replacement rate drops 50%. Premium choices save money over time in busy areas.

Common Selection Mistakes

Material mismatches create problems. CPE on dry floors increases slips by 30% in wet conditions. The waterproof surface gets too smooth. PP in chemical zones fails to block penetration. This raises contamination risks.

Ignoring slip ratings causes injuries. Non-SRC covers on wet steel floors drop friction below 0.3. This spike in fall incidents is 40% higher. Proper PVC soles reduce falls by 70%.

Wrong sizing ruins protection. Covers are too large for the feet to slip during movement. The covers are too small and rip right away. Test fit before bulk orders.

Industry Compliance Requirements

EN ISO 20345 safety standards require 200J impact resistance, 15kN compression strength, and SRC slip ratings. ASTM F2413 covers impact and compression. But it exempts overshoes from toe protection.

Match certifications to hazards. HRO ratings apply to hot contact above 300°C. FO ratings apply for fuel oil exposure (less than 1.0% volume change). CR ratings apply to cut resistance. Plants handling sharp materials need puncture resistance exceeding 1,000N.

Choose based on your specific risks. Generic covers fail compliance checks. They fail liability tests too.

How to Use and Store Shoe Covers?

Most contamination happens during removal, not application. Healthcare workers skip proper donning and doffing techniques. This turns protective barriers into germ spreaders. Follow these steps to maximize protection and avoid common mistakes.

Correct Application: The 3-Step Method

Step 1: Clean your hands first. Wash for 20 seconds or use alcohol-based sanitizer. Dirty hands contaminate clean covers before you even put them on.

Step 2: Sit or lean against a wall for balance. Slide one cover over your shoe. Pull the elastic or tie band tight above your ankle. Repeat with the other foot. Don’t touch the floor with your bare hands during this process.

Step 3: Check coverage. The cover should wrap around your entire shoe. No gaps at the heel or sides. Elastic bands must sit tight enough to stay put. They shouldn’t cut circulation.

When to Replace Shoe Covers?

Single-use shoe covers never get reused. Break this rule, and the contamination risk goes up. Studies show MRSA/VRE spread jumped from 2.6% to 4.0% with improper disposal of used covers. Change covers every time you move between contaminated and clean zones. ICU to operating room. Construction site to client space. Lab to office.

Reusable shoe covers need inspection after each use. Look for tears, worn spots, or visible contamination. Any damage means toss them out right away. Even tiny holes let germs through. The 1-in-10 patients affected by HAIs show why this matters.

Removal Without Contamination

Remove covers before touching clean areas. Peel them off from top to bottom. Touch the outer surface alone. Roll the contaminated side inward as you pull down. Drop straight into waste bins. Never set used covers on counters or floors.

Wash your hands right after removal. This step matters as much as the initial handwashing. Skip it, and you transfer everything the cover blocked straight to your skin.

Storage Best Practices

Keep unused disposable covers in the original packaging. Store boxes in dry, room-temperature areas. Keep them away from direct sunlight. Moisture weakens materials. Heat makes elastic bands degrade faster.

Reusable covers need proper cleaning between uses. Wash with hospital-grade disinfectant or commercial laundry detergent. Air dry all the way through. Damp covers grow bacteria. Store in sealed containers to prevent dust buildup.

Track inventory levels. Facilities using 20% of PPE budgets on shoe covers (about $15,655 annually) need consistent stock. High-traffic periods drain supplies fast. This creates gaps in protection protocols.

Common Mistakes to Avoid Using Shoe Covers

Shoe covers protect you when used correctly. Breaking basic rules and safety equipment becomes a contamination source. Here are the critical errors that ruin protection—and how to avoid them.

Never Reuse Disposable Shoe Covers

Single-use means single-use. Period. An ICU study tracked 1,151 patients and proved the danger. Culture-positive infections jumped from 30 cases before shoe cover use to 46 cases during improper use (p=0.004). MRSA, VRE, and Acinetobacter infections rose when staff reused disposables.

The problem starts during removal. Hands touch dirty surfaces. Germs transfer to skin. Walking spreads microbes through the air. Putting on dirty covers again spreads these germs everywhere.

Reused covers fail as barriers. Tiny tears let particles through. Dirt on shoes transfers straight to floors. One ready-to-eat food plant violated this rule. The result? $75,000 in annual hygiene violation costs plus employee balance problems from broken-down materials.

Choose Anti-Slip Materials for Wet Areas

Plastic-soled covers turn wet floors into ice rinks. Smooth PE or CPE materials lack grip on debris-covered or cleaned surfaces. Employees in food facilities struggle to walk safely. Covers bunch up underfoot after cleaning. This shifting raises trip risks.

Pick PVC-textured soles or SRC-rated non-slip shoe covers for wet areas. The waffle pattern grips wet tile and coated concrete. Standard smooth covers cause falls. Proper materials stop them.

Match Size to Footwear

Oversized covers slide off while you move. Workers trip on loose material at their toes. Small versions restrict normal walking. Elastic bands snap under tension. Shrinkage after cleaning makes a proper fit harder.

Test sizing before bulk orders. Covers should wrap tightly without cutting circulation. Wrong-sized covers detach while putting on and taking off. This creates the exact contamination you’re trying to stop.

Store Right to Prevent Breakdown

Moisture destroys protective materials fast. Damp storage speeds up aging. Bacteria grow well in humid conditions. Cleaned reusable covers wear out faster when stored wet or in sealed bags without full drying.

Keep unused disposables in original packaging. Store in dry, room-temperature spaces away from sunlight. Check reusable covers after washing. Throw away any with tears or worn spots. Damaged covers raise liability for injuries and cross-infection.

Use One Cover Per Clean Zone

Moving between rooms with the same covers defeats their purpose. You carry germs from dirty areas into clean spaces. Limit each pair to one environment. ICU to OR needs fresh covers. The construction site near the client’s home needs fresh covers.

This rule stops cross-room germ spread. The extra cost of new covers beats the price of infection outbreaks or floor damage.

Where to Buy Shoe Covers: Purchasing Guide and Price Ranges

You can buy shoe covers through three main channels: online platforms, local retail stores, and wholesale suppliers. Each channel has different prices and bulk options.

Online Platform Price Comparison

Jendco Safety Supply lists these typical online prices:

- Disposable Blue Polyethylene (1000/cs, XL) : $89.99 (MSRP $98.99) = $0.09 per pair

- Blue Polypropylene (150 pairs/cs, XL) : $69.99 (MSRP $76.99) = $0.47 per pair

- Kimberly-Clark Kleenguard A40 (200 pairs) : $169.00 (MSRP $185.90) = $0.85 per pair

- BootieButler ESD Non-Skid (750/cs) : $379.99 (MSRP $599.95) = $0.51 per pair

Bulk discounts give you 20-37% off MSRP. The BootieButler ESD pack saves you $220 compared to retail pricing.

ShuBee directly sells packs for $27.65-$79.95. Larger packs drop the per-unit cost much more.

Local Retail Options

Home Depot groups products by price:

- $0-$10 : Basic PE/CPE non-slip covers

- $10-$20 : Water-resistant models (HDX, Klein Tools brands)

- $20-$30 : Abrasion-resistant construction-grade

- $40-$100 : Premium packs with adjustable closures

Medical stores carry PP/SMS types at $0.40-$0.85 per pair. The higher price comes from stricter sterility standards.

Budget Guidelines by Use Case

- Household/Daily use : $10-30 per 100 pairs (basic PE)

- Medical-grade : $50-150 per 100 pairs (SMS/PP with certifications)

- Industrial/ESD : $300-500 per case (latex or specialty materials)

Bulk orders get you 20-40% discounts on 1,000+ units. Check suppliers for ASTM certifications first. Look for proper thickness (28mil for latex). Make sure they have non-skid soles. Do this before placing large orders.

Conclusion

Dirty floors, safety risks, and contamination all start with your shoes. The right shoe covers solve these problems fast by protecting floors, improving hygiene, and reducing slip hazards. From homes to hospitals and job sites, smart material choices matter. If you need custom shoe covers for your industry or brand, contact us for tailored options and competitive pricing.