It’s frustrating to wear protective clothing that feels hot, heavy, or still lets contaminants through. Many people don’t know there’s a better alternative. This article breaks down microporous coveralls in simple terms so you can understand how they keep hazards out while staying breathable. By the end, you’ll know whether this type of suit is the best choice for your job.

What Are Microporous Coveralls Made Of?

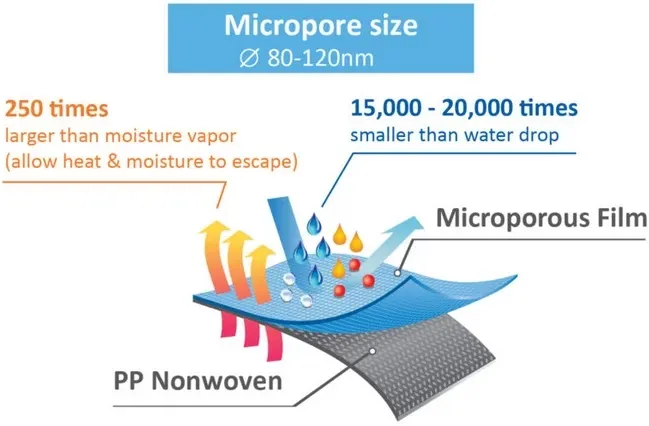

Microporous coveralls are made from a special fabric called microporous film-laminated fabric. This fabric combines a nonwoven polypropylene layer with a thin breathable polyethylene film. The film has tiny holes, or micropores, that are:

- 15,000 to 20,000 times smaller than water droplets, stopping liquids and dust from getting inside.

- 250 times larger than moisture vapor molecules, allowing sweat and heat to escape.

This design means the coveralls block liquids, dust, and fine particles while still being comfortable to wear for long periods.

Key Features of Microporous Fabric

Waterproof and liquid repellent: The fabric stops liquids like blood or chemicals from passing through. It meets strong safety tests like ASTM 1670, which checks for blood penetration.

Breathable: The material lets moisture vapor out, reducing heat build-up compared to ordinary polypropylene coveralls.

Durable: It resists wear and tear well, keeping its protection intact during use.

Lightweight: Weighing between 47 and 92 grams per square meter, most disposable coveralls are around 50–65 gsm for good comfort.

Why Microporous Is Better Than Standard Polypropylene

Regular polypropylene coveralls do not have breathable films. This traps sweat and heat, causing discomfort. Microporous coveralls have a high Moisture Vapor Transmission Rate (MVTR), helping heat and sweat escape. This makes them more comfortable, especially in hot or active work conditions.

Common Uses of Microporous Coveralls

- Painting and renovation: Protects against paint splashes and dust.

- Food processing: Blocks tiny food particles and liquids, and is gentle on the skin.

- Cleaning: Shields from light chemical splashes and dust.

- Laboratories and healthcare: Stops exposure to biological fluids and contaminants.

Additional features found in many products include anti-static treatment (to reduce dust attraction), reinforced areas for durability, and elastic closures for a better fit. Some are designed to be disposable and eco-friendly, with soft fabric inside for comfort during long work shifts.

Microporous coveralls provide a balanced solution with strong protection, breathability, and comfort across many industries.

Key Features to Look For in Microporous Coveralls

Microporous coveralls use special fabrics with tiny pores that block liquids and particles but let moisture escape. This design keeps you comfortable while providing protection. High-quality microporous films stand out with strong splash resistance and durability. They can protect well against tough chemicals like sulfuric acid and sodium hydroxide.

Types of Fabrics and Protection Levels

Flashspun polyethylene and microporous film laminates are common materials.

Microporous film laminates usually offer higher protection, such as Class 6 for liquid repellency and penetration.

Quality varies between disposable coverall manufacturers, so it’s important to choose reliable coverall brands.

Seam Construction: Serged vs. Taped Seams

Serged seams are sewn with thread and give basic strength, but may allow liquids to pass through tiny stitch holes.

Taped seams have a waterproof tape covering the stitches, greatly improving liquid resistance.

Taped seams are essential for high-risk environments and are required for Type 4 coveralls with heavy splash exposure.

Fit and Additional Protective Features

A proper fit covers the body fully and reduces gaps where contaminants could enter.

Elastic wrists and ankles help create a secure seal.

Hoods protect the head and neck, important for high-risk exposure.

Some coveralls include attached boot covers made from materials like PVC or polyethylene to protect feet and stop contamination.

Certification and Task Suitability

Type 5 coveralls protect against airborne particles (EN 13982-1 tested).

Type 6 coveralls protect against limited liquid splashes (EN 13034 tested).

Many models also have EN 14126 certification for infectious agent protection.

Choose coveralls based on task duration and risk:

- For short, low-risk tasks, lighter coveralls with serged seams may be enough.

- For longer, higher-risk jobs, use heavy-duty coveralls with taped seams, hoods, and boot covers.

Always check for damage before use and follow proper disposal rules after exposure.

6 Popular Microporous Coveralls Brands

Choosing the right disposable microporous coverall depends on your specific work environment and protection needs. Here are some well-regarded brands and what they offer:

Morntrip Microporous Protective Coveralls

Crafted from premium microporous film-laminated fabric that blocks liquids and fine particles while staying breathable.

Ideal for manufacturing, pharmaceutical production, industrial cleaning, food processing, and general maintenance work.

Engineered with a lightweight design that reduces heat buildup and increases comfort during long hours of wear.

Features elastic wrists, ankles, and hood, plus a secure zipper with a storm flap to enhance overall protection.

Available in multiple sizes for a reliable fit, and supports bulk orders to help lower the cost per use.

Trusted by global buyers for its balance of durability, comfort, and consistent barrier performance.

Microvek-Suits Heavy Duty by RAM

Made with high-grade microporous materials for durable protection.

Ideal for construction, painting, pharmaceuticals, and automotive industries.

Designed for comfort and breathability during long shifts.

Sold in bulk packs of 50 suits, reducing the cost per unit.

Great for repeated tasks that need reliable and lasting wear.

FrogWear Premium Microporous PE Film-Laminated Coveralls (NW-COV63)

Constructed from 55-gram anti-static microporous PE film-laminated material.

Perfect for cleanrooms and contamination-sensitive environments.

Features include reinforced triangle crotch, elastic ankles, waist, wrists, and hood.

Includes storm flap zipper and serged seams for durability and comfort.

Minimizes lint and boosts protection.

Lakeland MicroMax® NS Microporous Coveralls

Provides Type 5 & 6 protection against harmful dust, light chemical splashes, and fine particles.

Made with microporous film-laminated fabric that offers a strong liquid barrier while maintaining breathability.

Commonly used in pharmaceuticals, cleanrooms, industrial maintenance, and environmental cleanup work.

Available with multiple size guides and product variations to help users select the most suitable protection level.

A trusted, cost-effective choice for companies seeking reliable performance from an established global brand.

International Enviroguard MicroGuard MP Microporous Coveralls

Offers dependable Type 5 & 6 protection against airborne particles and light liquid splashes.

Built with microporous film-laminated fabric that balances durability with comfortable breathability.

Frequently used in laboratories, pharmaceutical production, environmental cleanup, and facility maintenance.

Comes with detailed size charts and product options to help teams choose the correct level of coverage.

A proven choice for organizations seeking consistent protection from a reputable safety-wear manufacturer.

Venom Steel Microporous Breathable Coveralls

Heavy-duty but breathable design for protection against wet and dry particles.

Flexible sizing available: L, XL, XXL.

Popular for painting, renovation, and janitorial work.

Known for a comfortable fit and staying in place during movement.

Easy to wear over regular clothes.

Selecting Microporous Coveralls: Key Considerations

Comfort: FrogWear and Venom Steel rank high for breathability and fit.

Protection Certifications: Look for Type 5 and Type 6 certifications for defense against dust and liquid splashes.

Customer Feedback: Venom Steel and Optimum receive positive reviews for fit, coverage, and price.

Price and Value: Optimum and Microvek-Suits offer bulk purchase options at lower unit prices, ideal for large worksites.

Usage Examples:

- Cleanrooms and pharmaceuticals: Optimum, FrogWear

- Construction and painting: Venom Steel, High Calibre

- Food processing: Shield Right

- Heavy-duty automotive work: Microvek-Suits by RAM

To ensure the best value and fit for your needs, ask for free samples where available and check user reviews focused on comfort and durability for long shifts.

Choosing the Right Size for Microporous Coveralls

Selecting the correct size of microporous coveralls is important for safety and comfort at work. Most disposable cocerall suppliers provide size charts based on your height and chest measurements, but sizes can vary between brands. Always check the specific chart before buying.

Typical Size Guide

| Size | Height (cm) | Chest (cm) |

|---|---|---|

| S | 162–170 | 84–92 |

| M | 168–176 | 92–100 |

| L | 174–182 | 100–108 |

| XL | 180–188 | 108–116 |

| 2XL | 186–194 | 116–124 |

| 3XL | 192–200 | 124–132 |

| 4XL | 200–206 | 132–140 |

How to Decide Your Microporous Coverall Size?

If you are near the upper limit of a size, it is better to size up. For example, if you are 178 cm tall with a 99 cm chest, choose size L instead of M.

Consider the clothing you will wear underneath the coveralls. In colder environments, wearing layers means sizing up is necessary.

Some brands offer custom fits or options for tall, short, or regular sizes to match different body types.

Fit and Movement Tips

After putting on the coveralls, test your movement by squatting fully and reaching overhead.

Make sure there is no pulling or tightness at the shoulder, crotch, or sleeves.

Avoid choosing coveralls that are too loose, as they can catch on objects and reduce protection.

Look for features like elastic or taped cuffs that keep sleeves secure while allowing freedom of movement.

Important Notes

Some disposable microporous coveralls come in sizes up to 5XL for larger chest measurements.

Standard inseam lengths are usually around 82 cm, but torso length may vary.

Popular brands like 3M, DuPont Tyvek, and Medtecs have similar size ranges, but it’s best to compare their specific charts.

Summary for Safe Sizing

Use height and chest measurements with brand size charts as your guide.

Size up if you need to wear layers or are close to the top size limit.

Always test movement in the coveralls before finalizing the fit.

Choose custom or tall sizes if your body proportions don’t fit standard sizes.

Don’t pick smaller sizes to avoid restriction and ensure safety on the job.

Microporous vs SMS vs PP vs Tyvek

Microporous coveralls provide a solid balance of breathability, durability, and protection. They are designed with a laminate film barrier that limits airflow more than SMS or polypropylene materials but still offers reasonable comfort for medium-duration use.

Breathability of Microporous Coveralls

Microporous disposable coveralls have moderate breathability.

The laminate film restricts airflow compared to SMS (Spunbond-Meltblown-Spunbond) or polypropylene (PP), which offer higher breathability.

Suitable for environments where some airflow is necessary but moderate protection is also required.

Durability of Microporous Coveralls

These coveralls offer moderate durability.

They effectively handle light chemical splashes and fine particulate protection.

Less robust compared to Tyvek, which is known for high abrasion resistance.

Best used where physical stress is limited but chemical and particulate barriers are needed.

Protective Features of Microporous Coveralls

Microporous coveralls provide high protection against fine particulates, sprays, and light chemical splashes.

They are rated for liquid protection at Types 4, 5, and 6 levels.

Ideal for tasks such as pharmaceutical work, asbestos removal, forensic analysis, paint spraying, and light chemical handling.

However, they are not fireproof and should not be used in environments with fire hazards.

Typical Use Cases

Used in laboratories, pharmaceutical settings, and food processing.

Common in forensic work and asbestos abatement.

Suitable for non-extreme chemical handling and environments requiring fine particulate protection.

Pricing and Cost Efficiency

- Microporous coveralls are typically priced in the low to moderate range.

- They offer good value for medium-level chemical and particulate protection without the high cost of premium options like Tyvek.

This combination of features makes microporous coveralls a practical choice for many industrial and laboratory applications where balanced breathability, moderate durability, and effective protection are essential.

How to Properly Wear and Remove Microporous Coveralls?

Wearing and taking off microporous coveralls correctly is essential to staying safe and avoiding contamination at work. Follow these simple steps to ensure protection and comfort.

Proper Donning Steps of Microporous Coveralls

- Choose the right coverall size for a snug fit. Avoid suits that are too tight or too loose to prevent tearing or hazards.

- Check the suit for any holes, rips, or zipper problems before use. Do not wear damaged coveralls.

- Take off your shoes and tuck your trousers into your socks.

- Step into the legs of the coverall and pull it up over your boots.

- Pull the suit over your arms and shoulders, then zip it up to your chest or chin.

- Put on your face mask or respirator, goggles, and pull the hood over your head for a tight fit.

- Pull your gloves over the sleeves, making sure the cuffs are covered.

- Close and secure the zipper and any storm flap to keep chemicals out.

- Move around a bit to make sure the suit fits well without strain on the seams.

Safe Doffing Steps of Microporous Coveralls

- Unzip the coverall carefully without touching the outside surface.

- Pull the hood and shoulders off, turning the suit inside out to trap contaminants.

- Remove gloves along with the sleeves, turning them inside out to contain dirt.

- Lower the suit to your hips, sit if possible, and pull off the legs inside out.

- Take off your boots carefully and put on clean shoes.

- Roll the used coverall into a bundle, handling only the clean inside.

- Wash your hands immediately after removing the suit.

Tips to Avoid Tearing and Damage

Always select the correct size for easy movement to reduce stress on seams.

Inspect high-stress areas like zippers, crotch, knees, and underarms.

Handle the suit gently when pulling it on; do not pull hard.

Stretch and move in the suit after wearing it to spot weak points.

Proper Disposal of Used Microporous Coveralls

Microporous coveralls are for single use only and should never be reused.

Remove and dispose of coveralls in designated areas to prevent contamination spread.

Fold or roll the suit inside out and place it straight into a hazardous waste bag or container.

Follow local regulations for disposing of suits exposed to biohazards or chemicals.

Do not throw contaminated suits in regular trash bins.

Additional Reminders

Always touch only the inside of the coverall during removal.

Incorrect removal increases the risk of cross-contamination.

Keep disposal bins clearly marked and close to your work area for easy access.

Some workplaces require multiple PPE checks daily to ensure safety.

Conclusion

Microporous coveralls provide reliable protection against dust, splashes, and light chemicals while staying breathable and comfortable for long wear. Choosing the right size, seam type, and protection level ensures safer work in labs, construction, cleaning, and more. For customized disposable coveralls or bulk orders, you’re welcome to contact us for a personalized quote.

FAQ For Microporous Coveralls

1. Are Microporous Coveralls Waterproof?

Microporous coveralls are water-resistant, not fully waterproof. They protect you from light splashes and non-hazardous liquids like petroleum oils, pesticides, bleach, and sodium hydroxide. These coveralls also provide a barrier against blood and bodily fluids, passing the EN14126 safety standard.

However, they are not meant for heavy liquid exposure or full submersion in liquids. Their strength lies in protecting against light splashes, droplets, and dry particles, making them ideal for many workplace hazards but not for continuous wet conditions.

2. Can Microporous Coveralls Be Reused?

Usually, microporous coveralls are designed as single-use disposable garments. This is to keep hygiene and protection at the highest level. But some brands claim their suits can be reused up to 10–15 times in low-risk environments where contamination is minimal.

Reuse depends on:

– The type of contamination risk

– The suit’s condition after each use

– Workplace safety rules

For high-risk jobs, like healthcare or food processing, it is best to avoid reuse to maintain safety standards.

3. Are Microporous Coveralls Safe for Mold Remediation?

Microporous coveralls are highly recommended for mold remediation and similar jobs, such as asbestos abatement or lead removal. They offer good protection from mold spores, dust, and light chemical splashes.

Key points for mold remediation:

– They protect better than traditional polypropylene suits

– Should be combined with respirators for full protection

– Must fit well to ensure no exposure to harmful particulates

4. How Long Do Microporous Coveralls Last?

These coveralls are generally made for single-use during one hazardous task or a full work shift, usually about 8 hours. In some low-risk cases, they can be reused 10–15 times, provided they are not damaged or heavily soiled.

Factors influencing lifespan:

– Intensity of the task

– Exposure type

– Inspection protocols to check integrity before reuse

5. Which Brand Offers the Best Value for Microporous Coveralls?

Several brands are popular and trusted for microporous coveralls:

–Tyvek® : Known for strong protection

– Multi-Gard™ : Comparable to Tyvek®, but more economical (around $2.96 per suit in bulk), and meets EN14126 biological hazard standards

– Micromax®, Nexgen®, Posiwear® also offer reliable options

Additional details:

– Case packs contain 25 suits, sized L to 3XL

– Materials mostly polyethylene-laminated polypropylene or 100% polyolefin

– Designed with elastic wrist, ankle, waist bands, and hooded versions are available