You’ve probably had moments on the job when a truck or machine passed too close, making you realize how invisible you felt. That’s why High Visibility Coveralls are worth understanding. In this guide, you’ll get a simple breakdown of what they are and how they help you stay clearly seen in busy or low-light work areas.

Why High Visibility Coveralls Are Essential for Worker Safety?

High visibility coveralls significantly improve worker safety by making workers easier to see in dangerous environments. Their bright neon colors, such as yellow and orange, combined with reflective tape, ensure workers stand out, even in poor lighting or complex backgrounds.

Proven Accident Risk Reduction

Wearing hi-vis coveralls leads to a 12% drop in nonfatal injuries in construction and manufacturing.

In road maintenance and construction, there is a 15% decrease in fatal injuries after adopting high-visibility standards.

A Danish study found that cyclists wearing hi-vis jackets experienced 47% fewer accidents per month and 55% fewer vehicle-related accidents.

Since roadway incidents are a leading cause of fatal worker injuries, hi-vis gear is crucial, especially as 1 in 4 struck-by-vehicle deaths involve construction workers.

Key Safety Situations for Hi-Vis Coveralls

Night and low-light work: Essential for crews working on highways, roadsides, and emergency responders at night. Reflective tape helps headlights spot workers from a distance.

Traffic zones: OSHA requires high-visibility clothing for workers exposed to vehicle traffic—construction, paving, and airport crews included.

Equipment operation: In factories and warehouses, hi-vis helps drivers of forklifts and cranes see workers quickly, lowering collision risks.

Emergency response: Hi-vis coveralls assist in quickly identifying and accounting for team members during emergencies or evacuations.

Impact and Effectiveness

Standardizing high visibility coveralls reduces workplace accidents by 45%.

There are 10% fewer illness cases in hazardous chemical environments due to less accidental contact.

Incident rates involving fire and air quality hazards drop by 20% when hi-vis clothing is used.

What Makes High Visibility Coveralls Work?

- Fluorescent colors provide high visibility in daylight and dim light.

- Reflective tape enhances visibility at night by reflecting vehicle lights.

- Durable materials ensure these safety features last through tough work conditions.

In short, high visibility coveralls play a vital role in protecting workers by reducing accidents and improving safety in low-light, traffic, and heavy equipment environments.

Types of High Visibility Coveralls and Their Uses

High visibility coveralls come in different types, each designed to meet specific needs and work environments. Understanding these types of high visibility coveralls helps you choose the right coverall for safety and comfort.

Basic High Visibility Coveralls

Basic hi-vis coveralls are made from fluorescent fabric, usually safety yellow or safety orange. They do not have reflective tape. These coveralls are lightweight and breathable, making them suitable for daytime use in low-risk areas with little traffic or machinery. They are common in warehouses, landscaping, and light industrial work.

Reflective Tape Coveralls

These coveralls have reflective strips sewn onto the fluorescent fabric. The reflective tape improves visibility during the day and night, especially in low-light conditions. They are ideal for jobs like construction, roadwork, and utility work, where workers face moving vehicles or equipment.

Insulated Winter High Visibility Coveralls

Designed for cold weather, high visibility insulated coveralls have thermal lining that keeps workers warm. They combine fluorescent fabric and reflective tape for high visibility. These are used by snow removal crews, utility workers, and highway maintenance teams working outdoors in winter.

Flame-Resistant (FR) High Visibility Coveralls

FR hi-vis coveralls protect against fire and electric arc hazards. Made from flame-resistant materials, they self-extinguish when exposed to flames. These coveralls offer both high visibility and safety, suited for workers in oil and gas, electrical utilities, and other high-risk industrial settings.

Waterproof High Visibility Coveralls

Waterproof coveralls protect against rain and wet conditions while maintaining visibility with fluorescent fabric and reflective strips. They are perfect for outdoor tasks in rainy or wet environments, such as road construction, utilities, and emergency response.

Summary of Protection Levels and Typical Uses

| Type | Protection Level | Common Uses |

|---|---|---|

| Basic Hi-Vis | Low protection | Warehouses, landscaping, light industrial |

| Reflective Tape | Moderate protection | Construction, roadwork, utility work |

| Insulated Winter | Moderate to high | Snow removal, highway maintenance |

| Flame-Resistant (FR) | High | Oil and gas, electrical, high-fire risk areas |

| Waterproof | Moderate to high | Road construction, emergency response |

ANSI/ISEA Safety Ratings: Choosing the Right Visibility Class

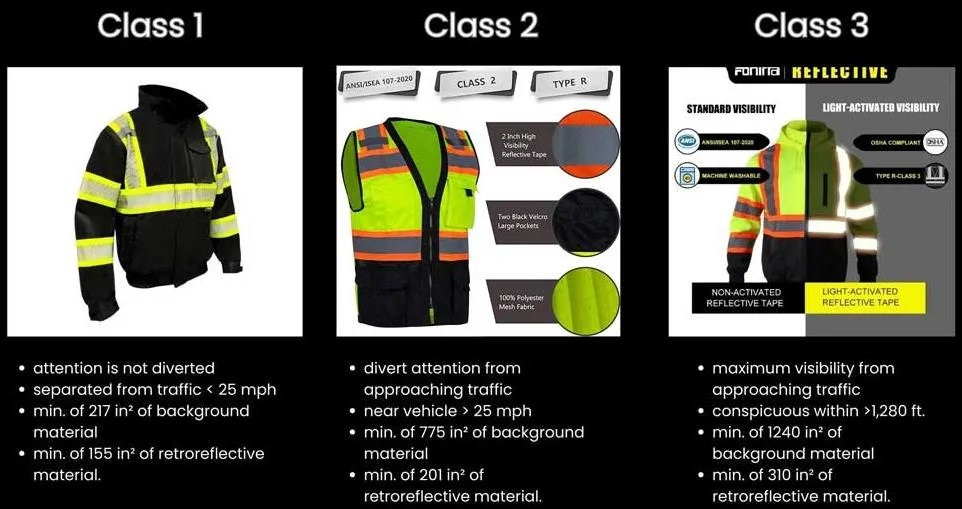

ANSI/ISEA safety ratings categorize high visibility coveralls into three classes based on risk and work environment:

- Class 1: Lowest coverage for low-risk jobs where traffic moves under 40 km/h (25 mph). Suitable when workers are fully attentive and vehicle speed is low.

- Class 2: Moderate coverage for medium-risk areas with vehicle speeds between 40-80 km/h (25-50 mph) and complicated backgrounds.

- Class 3: Highest visibility for high-risk jobs with vehicle speeds over 80 km/h (50 mph), nighttime work, or situations needing full body visibility up to 390 meters (1,280 feet).

Selecting the right class is crucial for safety, especially around fast-moving machinery or traffic.

Fabric Strength and Durability

Coveralls use strong fabrics like 300 denier polyester that resist tears and abrasions. Depending on the job hazards, materials may also require:

- Flame resistance

- Thermal protection

- Water resistance

- Breathability for comfort

These features ensure protection in tough industries such as construction, mining, and oil & gas.

Reflective Tape Placement for Maximum Visibility

Regulations require a specific reflective tape arrangement to guarantee visibility:

- At least one horizontal retroreflective band around the waist

- Reflective tape on sleeves

- Minimum tape width of 50 mm

- Vertical stripes over the shoulders in front and an “X” pattern on the back

- For Class 3, additional bands encircle arms and legs

Correct tape placement ensures workers are visible from all angles and distances, especially at night or in low light.

Color Visibility and Contrast

High visibility coveralls are made in bright fluorescent colors, like:

- Yellow-green

- Orange-red

- Bright yellow-green

- Bright orange-red

While these bright colors improve visibility, they do not replace retroreflective tape, which is essential for night visibility. Employers should pick color and stripe combinations that offer strong contrast and clearly show worker movement.

Practical Features: Pockets, Zippers, and Waterproofing

Coveralls often include:

- Detachable parts (hoods, liners) for changing weather

- Leg zippers allow easy on/off without removing boots

- Waterproof materials to keep workers dry and maintain visibility in wet or dirty environments

Breathable but waterproof fabrics allow sweat to escape while blocking rain and contaminants, balancing protection and comfort.

Comfort Elements: Breathability and Insulation

Good coveralls let air circulate to prevent overheating or fatigue during long shifts. In cold weather, insulation like Thinsulate lining keeps workers warm without bulk, preserving mobility and safety on the job.

Common Materials Used in High Visibility Coveralls

High visibility work coveralls come in various materials, each offering different benefits for durability, comfort, and visibility. Choosing the right material depends on your work environment and safety needs.

Polyester Coveralls

Durability: Very strong, resists wear and maintains shape after many washes.

Comfort: Less breathable, might feel warm in hot weather.

Visibility: Excellent for bright, fluorescent colors that stay vivid in daylight and low-light conditions.

Example: Portwest Class 3 Hi Vis Quilt Lined Coveralls are made from 100% polyester 300D Oxford fabric.

Poly-Cotton Blend Coveralls

Durability: Good balance—polyester adds strength, cotton adds softness.

Comfort: More breathable and comfortable than pure polyester, suitable for long wear.

Visibility: Slightly less bright than polyester but still effective.

Example: Tough Duck S792 uses a 65% polyester and 35% cotton twill fabric.

Flame-Resistant (FR) Cotton Coveralls

Durability: Less durable than polyester but improved by FR treatments; more costly.

Comfort: Soft and breathable, preferred in moderate temperatures.

Visibility: Colors may fade faster, often paired with reflective tape for visibility.

Example: Neese VI9CAE Indura Cotton FR coveralls with visible safety strips.

Waterproof PVC or PU-Coated Coveralls

Durability: Highly resistant to water, chemicals, and abrasions.

Comfort: Less breathable, can feel hot without ventilation.

Visibility: Keeps color well, even in wet and dirty conditions, often enhanced with reflective tape.

Example: Occunomix LUX-WCVL with PU waterproof coating and sealed seams.

Additional Tips

Look for ANSI Class 2 or 3 ratings, which indicate minimum standards for background material and reflective tape.

Polyester coveralls usually last 2–3 years, while cotton blends wear out faster with heavy washing.

Choose materials based on your work conditions: waterproof fabrics for wet jobs, FR cotton for fire risk areas, poly-cotton blends for comfort in less harsh environments.

Price Examples

- Poly-cotton blend coveralls like Tough Duck S792 typically range from $99 to $119.

Selecting the right material helps ensure safety, comfort, and durability in your high visibility coveralls.

Key Industries Using High Visibility Coveralls

High visibility safety coveralls are vital safety gear in several industries where worker visibility can prevent accidents. These industries use coveralls designed to meet their specific safety needs, helping reduce workplace injuries.

Construction

In construction, hi-vis coveralls are essential to protect workers in busy sites with heavy machinery and vehicles. These coveralls are made from fluorescent fabrics with strong reflective strips. Safety rules like OSHA and EN ISO 20471 require their use near cranes, trucks, and excavators. With infrastructure projects rising in 2023, the global market for hi-vis gear in construction reached over USD 1.8 billion.

Road and Highway Work

Road crews and traffic police wear hi-vis coveralls to stay visible to drivers in poor light or bad weather. Their coveralls feature extra reflective tape for all-around visibility, crucial for night shifts or fog. Regulations in the US, EU, and Asia strictly enforce wearing these coveralls to reduce roadside accidents.

Logistics

In logistics and warehousing, workers wear hi-vis coveralls to stand out around fast-moving forklifts and machines. Using these coveralls has helped lower accidents by up to 47%. They are generally light and moisture-wicking, providing comfort during long work hours.

Mining

Miners use hi-vis coveralls made from flame-resistant and tough materials to endure rough underground conditions. Bright colors and reflective stripes make it easier to locate workers during emergencies or in dark mine tunnels.

Oil and Gas

The oil and gas industry requires flame-retardant hi-vis coveralls that protect against fire and chemical risks. These garments also have anti-static features and sealed seams for harsh environments near drilling rigs and refineries.

Utilities

Utility workers handling electricity, water, or telecom use hi-vis coveralls that are lightweight, weatherproof, and insulated. This gear helps them stay visible and comfortable during outdoor repairs and maintenance tasks year-round.

Airport Ground Crews

Airport staff, like ground handlers and marshals, wear hi-vis coveralls with extra reflective surfaces and neon colors to ensure visibility during busy, noisy operations during day and night. Microprismatic materials enhance recognition in large airport areas.

Industry-Specific Features of Hi-Vis Coveralls

Construction: Durable, weather-resistant, with wide reflective bands

Road & Highway: Extra reflective tape, waterproof, meets traffic safety standards

Logistics: Lightweight, moisture-wicking, ergonomic design

Mining: Flame-retardant, abrasion-resistant, high-contrast stripes

Oil & Gas: Dual-certified for fire resistance and visibility, anti-static coating

Utilities: Insulated, quick-drying, multi-season use

Airport Ground Crews: Neon colors, microprismatic reflectors, weather protection

Market Insights and Safety Impact

The global hi-vis clothing market was valued between USD 1.6–1.9 billion in 2023, expected to reach USD 3.3 billion by 2033

Construction and roadwork lead demand due to infrastructure growth in Asia, Europe, and North America

New technologies include moisture-wicking fabrics, flame resistance, and smart features like GPS tracking

North America dominated adoption in 2023, with the US holding 78.5% of the market share

Workplace accidents dropped by up to 47% in areas with mandatory hi-vis clothing

High Visibility Coveralls vs Jackets and Vests: What’s the Difference?

High visibility coveralls provide full-body hi vis protection, covering the torso, arms, and legs for 360° visibility. This is important for workers who need to be seen from all directions, especially in poor light or complex environments.

Coverage and Safety Levels

Coveralls: Offer complete coverage, reducing blind spots caused by movement or gear. They are usually rated Class 3, the highest safety level, visible from up to 1,280 feet at night.

Jackets: Cover torso and arms, sometimes neck, and can provide weather protection. They are better than vests, but don’t cover legs fully.

Vests: Lightweight and breathable, covering only the upper torso. Often less safe (Class 1 or 2) and suited for low-risk, indoor, or warm settings.

Use Cases

Coveralls are best for roadway construction, emergency responders, utility and mining workers, or any job needing maximum visibility with complex backgrounds or poor lighting.

Jackets suit outdoor work needing weather protection with moderate visibility.

Vests work well indoors or in simple outdoor jobs where only upper body visibility is needed.

Why Choose High Visibility Coveralls?

Coveralls eliminate gaps in visibility caused by bending or overlapping gear.

For hazardous or high-speed work, coveralls meet strict Class 3 standards and maximize safety.

Unlike vests, coveralls often combine weather protection and hi vis in one, preventing loss of visibility if layered.

How to Choose the Right High Visibility Coveralls for Your Job?

Choosing the right hi-vis work coveralls is key to staying safe and comfortable on the job. Here are the main factors to consider:

Job Type and Work Environment

Type O coveralls suit off-road jobs without traffic.

Type R Class 2 or 3 coveralls are best for roadway exposure or busy warehouses.

Choose orange gear near yellow equipment and yellow gear near orange containers to stand out.

Safety Standards and Classes

Coveralls must meet ANSI/ISEA 107-2020 standards.

Class 1: Basic visibility, for low-risk work.

Class 2: Moderate coverage with reflective tape, good for utility workers.

Class 3: Maximum visibility, visible from up to 1,280 feet.

Lighting and Material

Use fluorescent materials in daylight.

Add reflective tape for dawn, dusk, or low light.

At night, prefer retroreflective materials for the best visibility.

Fit and Comfort

Coveralls must fit well and allow free movement.

Choose options made for different body types, including women.

Materials should be lightweight, flexible, and irritation-free.

Extra Protection

In heat, use coveralls that wick moisture and block UV rays.

For cold or wet weather, insulated or rainproof high visibility coveralls help maintain comfort.

Layers that can be added or removed improve adaptability.

Durability and Cost

Pick coveralls with abrasion-resistant fabrics and strong reflective tape.

Investing in durable gear saves money and protects safety long-term.

How to Properly Care for High Visibility Coveralls?

Proper care extends the life of your hi-vis coveralls and keeps you safe on the job. Here’s how to maintain their visibility and durability.

Washing Tips for Hi-Vis Coveralls

Always wash coveralls inside out to protect reflective strips.

Use a cold, gentle cycle with a mild detergent only.

Avoid bleach, fabric softeners, and harsh chemicals—they harm fluorescent fabric and reflective tape.

Wash coveralls separately from other clothes, especially dark or rough-textured items.

For tough stains, apply spot cleaners like OxiClean or Shout gently, avoiding scrubbing reflective parts.

Drying and Storage Guidelines

Air dry in shade, away from direct sunlight to prevent fading.

If machine drying, set to the lowest heat and remove the coveralls right after drying.

Never iron or dry-clean hi-vis coveralls.

Store them carefully to avoid crushing reflective tape.

When to Replace Hi-Vis Coveralls?

Replace work coveralls showing fraying, tears, peeling reflective tape, or fading fluorescent colors.

Retire any garment no longer meeting ANSI/ISEA 107-2020 standards.

Regular inspections before and after use ensure ongoing safety and compliance.