Many people don’t realize how much ordinary work clothes leave them exposed to hazards. From laboratories to construction sites, hidden risks like dust, liquids, and infectious agents can create problems. Here, we explain what disposable coveralls are used for and which industries rely on them. You’ll discover why these single-use suits improve safety and make daily work easier for staff.

Applications of Disposable Coveralls in Different Industries

Disposable coveralls keep workers safe and clean across many sectors. I’ve seen how their flexibility and low cost drive market growth. The global market should reach $6.2 billion by 2032. Some forecasts even suggest $1,310 billion by 2036.

1. Healthcare and Cleanroom Hygiene Protection

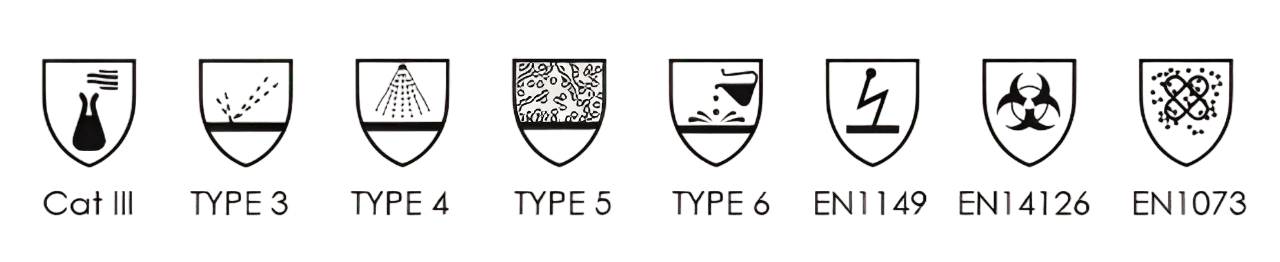

In healthcare, I recommend disposable coveralls for infection control. They protect staff from fluid splashes and aerosols. They also help keep areas sterile. Laminated polypropylene materials resist fluids well. They maintain sterility, too. Coveralls with EN14126 certification guard against infectious agents. I suggest these for cleanrooms where contamination risk runs high.

2. Manufacturing and Logistics Safety

Manufacturing and logistics use the most disposable coveralls. Workers need protection in many settings. Hot factories, cold storage, and dusty warehouses all require them. SMS (Spunbond-Meltblown-Spunbond) materials block dust and light chemicals. Based on my experience, fast donning and removal boost workplace efficiency. They don’t sacrifice protection either.

3. Construction Worker Protection

Construction pros need disposable protective coveralls to guard against dust, splashes, and sharp objects. Breathable and lightweight polypropylene designs keep workers comfortable during active work. Basic polypropylene suits handle dirt and minor splashes well. They create an important barrier against construction hazards.

4. Food Processing and Agricultural Use

Food processing and agriculture sectors use disposable coveralls to stop contamination. These suits block dust, hair, and bacteria from clean environments. Chemical-resistant suits give extra protection. I recommend them for workers who handle pesticides and fertilizers. Type 4B/5B/6B coveralls meet strict standards like EN14605 Type 4B and EN13982-1 Type 5B. They handle both liquid and solid chemical risks.

5. Warehousing, Distribution, and High-Risk Industrial Environments

Warehousing and distribution companies give staff disposable coveralls for jobs with hazardous materials or equipment. Not every job needs them. But specific duties need apparel that stops chemicals, sharp objects, and contaminants. In wood and metal processing, Type 5/6 coveralls meet EN13982-1 Type 5 and EN13034 Type 6 requirements. They protect against airborne and splash hazards.

6. Chemical, Petrochemical, and Emergency Response Needs

The petrochemical sector needs strong protection. Type 3B/4B coveralls with EN14605 Type 3B certification guard against strong chemical jets. Emergency responders and disaster relief workers appreciate disposable coveralls. They store easily and deploy fast. I’ve found they protect against many hazards. These include infectious waste and chemical spills. They also stop further contamination.

7. Specialized Uses: Nuclear Facilities and Painting

In nuclear maintenance, Type 5B/6B coveralls with EN1073-2 certification block radioactive particles. For painting jobs, disposable coveralls prevent skin contact with harmful chemicals. Hoods add defense against airborne paint particles.

Key Benefits of Disposable Coveralls: Full-Body Protection, Hygiene Control & Compliance

I recommend disposable coveralls for full-body protection. They create a strong barrier against harmful chemicals, infectious agents, and dangerous substances. Standard work clothes can tear easily during tough tasks. Disposable coveralls resist this damage. Workers stay safe from many hazards:

Chemical and biological threats

Mechanical injuries (scrapes, cuts)

Thermal and electrical risks

Electromagnetic particle exposure

360-Degree Hygiene and Contamination Control

Disposable safety coveralls provide complete coverage. This matters most in clean environments. I suggest them for healthcare, food processing, and laboratories. They stop harmful substances from moving back into the workspace. You throw these coveralls away after use. This prevents contaminants from spreading through shared or reused clothing.

Studies show a 37.6% decrease in workplace injuries and illnesses with disposable coveralls. You must use them with other PPE and proper training.

In hospitals, pharmaceutical plants, and painting workshops, single-use coveralls help meet strict hygiene standards.

Operational Ease and Cost Effectiveness

Based on my experience, disposable coveralls make workflows more efficient. Employees put them on and take them off fast. No laundry or extra maintenance steps needed.

You save time and money. No washing, drying, or decontamination required.

They work well for short-term projects or tasks with recurring hazardous exposure. No need to stockpile spare garments.

The global disposable coveralls market size is expected to increase from $3.5 billion in 2023 to $6.2 billion by 2032. It may reach $1,310 billion by 2036 (CAGR: 6.5%).

Comfort and Material Benefits

I like how disposable coveralls use lightweight materials. These materials are tough but comfortable.

Tyvek nonwoven fabric (DuPont) excels at tear resistance. It has a high strength-to-weight ratio. It breathes well and protects against liquids.

Long sleeves, full-length legs, hoods, and elastic cuffs shield workers. They can still move with ease.

Breathable designs suit active or extended tasks. Construction sites benefit most from these designs.

Regulatory Compliance with Safety Standards

I suggest disposable coveralls to help companies meet safety and hygiene rules.

They protect workers from asbestos exposure. This prevents lung problems.

Hospitals and cleanrooms can follow strict infection control mandates.

Food safety rules become easier to follow. Disposable coveralls prevent bacteria, dust, and hair from entering processing environments.

Manufacturers and food plants get quality assurance. Single-use coveralls are easy to use and support regulatory compliance.

Types and Variants of Disposable Coveralls: Protection Levels, Materials, and Features

Disposable coveralls come in several types—Types 3B, 4, 5, and 6. Each type targets specific hazards and work conditions.

EN Coverall Types and Their Applications

| Standard Type | Description | Recommended Usage |

|---|---|---|

| Type 3B (EN 13982-1) | Full-body suits with sealed seams. |

|

| Type 4 (EN 14605) | Suits with sealed seams, elastic cuffs, and hoods. |

|

| Type 5 (EN ISO 13982-1) | Protects from airborne solid particles, dust, and fibers. Includes taped or covered seams. |

|

| Type 6 (EN 13034) | Lightweight suits with basic splash protection for light liquid exposure. |

|

Construction Materials and Protection

Polypropylene:

Single-layer, low-cost, and lightweight. Use it for general maintenance and dust.

SMS (Spunbond-Meltblown-Spunbond):

Three layers provide liquid and particle resistance with good comfort. I like these for medical, food, or pharma tasks.

Tyvek®:

Made from high-density polyethylene. It blocks particulates and liquid splashes better than most. It’s durable and lightweight. I recommend it for hazardous abatement and spray-painting.

Microporous:

Polypropylene with microporous film. It balances splash and particle protection with comfort.

Polyethylene-Coated:

Gives you extra liquid protection. People often use it in painting and pesticide work.

Advanced Features and Usability

Seam Types:

Serged seams are basic. Taped seams create a particle barrier for Type 5/6. Sealed or welded seams make suits liquid-tight for Type 3B/4.

Hood and Cuff Options:

Integrated hoods, elastic cuffs, thumb loops, and boot covers help in high-contamination or chemical zones.

Ventilation:

Breathable materials like SMS, Tyvek®, and microporous fabrics reduce heat. This helps during extended wear.

Closures:

Storm flaps, locking zippers, and Velcro make suits safer for splash and spray risks.

Extra Elements:

Sealed pockets, reinforced stress points, and visibility stripes add value.

Materials and Cost Comparison

| Type | Best for | Material Example | Relative Cost |

|---|---|---|---|

| 3B/4 | Liquid/chemical splashes | Tyvek®, microporous | $$$ |

| 5 | Dust/particles, asbestos | SMS, Tyvek® | $$ |

| 6 | Light splashes | Polypropylene, SMS | $ |

You select disposable PPE coveralls based on risk. Consider hazardous chemicals, dust, or light splashes. Think about what your industry needs. Tyvek® options last longer in harsh environments. But they cost more. Polypropylene and SMS give you affordable flexibility. I suggest them for short-term, low-risk jobs.

How to Choose the Right Disposable Coverall for Your Industry?

I recommend you pick the right disposable coverall by knowing your industry’s safety needs and risks. Here are the steps and factors to help you choose.

1. Assessing Industry-Specific Risks and Hazards

Identify main hazards:

Construction: dust, asbestos, chemical splashes

Pharmaceuticals: powders, biological agents, sterile conditions

Food processing: hygiene, particle contamination

Typical examples:

Asbestos removal risks inhaling fibers

Chemical plants need protection from splash and aerosols

Cleanrooms must avoid particle contamination

Risk level matters:

Disposable coveralls must meet “Category III” PPE standards. This applies to serious or irreversible hazards.

2. Selecting the Right Protection Level and Material of Disposable Coverall

Hazard types:

chemical, biological, particulate

Coverall types:

Type 5: Hazardous dust/particles (EN 13982)

Type 6: Light sprays/liquids (EN 13034)

Higher types: Type 1 (full chemical), Type 4 (spray-tight)

Material options:

Tyvek®/Microporous Coverall: Great for particles and limited splash. Less breathable.

SMS Coverall: Good splash/particle barrier. Breathable. Filtration rates: 55 gsm (blocks 10-micron), 45 gsm (30-micron).

Polypropylene Coverall: Lightweight. Basic. For short-term or hygienic use.

Extra features:

anti-static (EN 1149-5), welded seams for liquids, biological hazard (EN 14126)

Example:

For electronics, I suggest you choose anti-static. For biological risks, confirm EN 14126 cert.

3. Size, Fit, and Comfort Considerations of Disposable Coverall

Sizing standards:

ANSI/ISEA 101-2014 ensures minimum body coverage and movement

Fit checklist:

Should not restrict work

Adjustable closures (elastic cuffs, hoods, boot covers)

Reinforced stitching where needed

Comfort:

Breathable: SMS and certain microporous films

More comfort: Knitted cuffs instead of elastic

Climate:

Pick breathable fabrics for heat. Add layers in cold.

4. Regulatory Standards and Certifications of Disposable Coverall

Key standards to verify:

- ANSI/ISEA 101-2014 (US sizing/label)

- EN 13982 (Type 5), EN 13034 (Type 6), EN 14126 (bio), EN 1149-5 (antistatic)

- OSHA compliance with hazard training and clothing features

Certification:

EN 369 chemical penetration testing

Labeling:

Must show protection level, material, size, and certs as per ANSI/ISEA 101

Always check:

The coverall must meet both hazard-specific and local rules.

Practical Checklist for Selection

Assess your industry’s specific hazards

Match coverall protection type (5, 6, higher) to the risks

Select the right material for hazard, comfort, and job duration

Ensure size, secure fit, and range of motion

Confirm valid and updated certifications

Review all labeling for clarity and compliance

Train teams in selection and proper usage

How to Use, Dispose of, and Understand the Environmental Impact of Disposable Coveralls?

I recommend using and disposing of disposable coveralls the right way. This protects workers and reduces contamination.

Putting on coveralls:

Check for any tears or defects first. Secure all fasteners. Close the cuffs. Zip up completely. Make sure no skin is exposed.

Taking off coveralls:

This step is critical. Peel the coverall from top to bottom. Turn it inside out as you remove it. Place it in a designated waste container right away. I suggest treating disposable coveralls as single-use items only. Washing them does not remove hazardous agents.

How to Dispose of Disposable Coveralls Safely?

After you remove disposable nonwoven coveralls, put them in heavy-duty plastic bags. Seal the bags.

If coveralls are contaminated, label the bag as hazardous waste. Follow your local health and environmental rules.

Two main disposal methods are used around the world:

Landfill:

Millions of coveralls go to landfills. Synthetic fabrics like polypropylene or polyethylene last for hundreds of years. This takes up huge amounts of landfill space. It also risks chemicals leaking into soil and water.

Incineration:

This method reduces waste volume. It can generate energy. But it may emit toxic pollutants (like dioxins) and greenhouse gases. This happens without advanced emission controls.

Environmental Impacts and Better Alternatives

Based on my experience, disposable coveralls cause serious environmental harm:

– High volumes create major microplastic pollution.

– The entire product life—from resource extraction to manufacturing, transportation, and disposal—produces greenhouse gas emissions.

– Reusable coveralls are used 15–20 times. Disposables add more to global warming, freshwater eutrophication, and toxicity. Reusable models do use more water for laundering.

Waste Management Examples:

– Place contaminated PPE in labeled hazardous waste containers.

– Use controlled waste streams. Or participate in specialty recycling programs. I like the ReWorked Zero Waste Recycling Box. These programs divert waste from landfills and incinerators.

| Waste Challenge | Impact |

|---|---|

| Landfill Space | Takes up large volumes worldwide |

| Chemical Leaching | Toxins may enter soils and waters |

| Air Pollution | Incineration releases toxic substances |

| Resource Depletion | Uses nonrenewable oil-based materials |

| Climate Change | Emissions from the production and disposal stages |

I suggest sustainable approaches. Shift to reusable coveralls. Use recycled materials. Support take-back or recycling schemes for disposable PPE.

Conclusion

Disposable coveralls provide essential protection against dust, chemicals, and biological hazards across many industries. From healthcare and food processing to construction and chemical handling, choosing the right type ensures safety, hygiene, and comfort for workers. Understanding materials, protection levels, and proper usage helps prevent accidents and contamination. If you are looking for customized disposable coverall solutions to meet your workplace needs, feel free to contact us for a quote and expert guidance.

Frequently Asked Questions For Disposable Protective Coveralls

1. Are disposable coveralls waterproof?

Some disposable coveralls are designed to resist liquids, but it depends on the type and material. Type 3B and Type 4 coveralls can handle sprays, splashes, and pressurized liquids. Type 5 and 6 provide only light protection against small splashes or dust and are not fully waterproof. Always check the coverall type before using it in wet or chemical environments.

2. Can disposable coveralls be reused?

No, disposable coveralls are meant for single use only. Reusing them can reduce their protective abilities and may spread contaminants. Always discard them after one use, especially if they have been exposed to chemicals, dust, or biological hazards.

3. How do I choose the right disposable coverall?

Choosing the right coverall depends on your workplace risks. For dusty or particle-heavy jobs, Type 5 or 6 is suitable. For chemical or liquid hazards, Type 3B or 4 is recommended. Consider size, fit, and material. Make sure the coverall allows easy movement, has proper closures like zippers or elastic cuffs, and meets relevant EN or ANSI/ISEA standards.

4. Can disposable coveralls protect against chemicals?

Yes, but protection varies by type and material. Type 3B and 4 coveralls are made for chemical splash or pressurized spray hazards. Type 5 and 6 offer limited protection for light liquid exposure. Always verify the certification and choose coveralls suited to the specific chemicals you may encounter.

5. Are disposable coveralls comfortable to wear?

Modern disposable coveralls are lightweight, breathable, and designed for extended wear. Materials like SMS or microporous fabrics allow airflow while still providing protection. Features such as elastic cuffs, hoods, thumb loops, and adjustable closures help workers stay comfortable and move freely during long shifts or physically demanding tasks.

6. Do disposable coveralls require special training to use?

Yes, proper donning (putting on) and doffing (taking off) techniques are crucial to avoid contamination. Workers should follow instructions carefully, secure all fasteners, and remove the coverall without touching the outside surface. Using disposable coveralls with other PPE and proper safety training ensures maximum protection against chemical, biological, or particulate hazards.