Ripping your coverall suit halfway through a rough job is frustrating and dangerous. You don’t want to waste money replacing gear constantly, but buying cheap options often costs more in the long run. That is why the choice of Tyvek vs KleenGuard matters so much. Let’s break down the real differences to help you pick the right disposable coverall .

Tyvek Disposable Coverall Material Technology and Protection Characteristics

DuPont makes Tyvek using a special flash-spun polyethylene process. This sets it apart from regular fabrics. High-density polyethylene (HDPE) gets extruded into very fine fibers. These fibers measure just 0.5-1.0 micrometers in diameter. That’s 50 times thinner than a human hair. The continuous filaments spin together and bond under heat and pressure. No chemical binders needed.

The result? A nonwoven material with connected molecular structures. Different bonding methods create different textures. Hard, paper-like versions (Types 10 and 14) suit industrial wrapping. Soft, fabric-like variants (Type 14) work better for protective clothing types. Tyvek weighs just 0.38 g/cm³. That’s about half the weight of paper. Yet it stays strong.

Core Performance Metrics

Tyvek 400 is the standard for disposable coveralls . It delivers measurable protection across multiple areas:

-

Thickness : 5.9 mils (ASTM D1777)

-

Burst strength : 50 psi (ASTM D774)

-

Breaking strength : 18 lbf/in lengthwise, 22 lbf/in crosswise (ASTM D5034)

-

Seam strength : Over 19 lbf (ASTM D1683)

-

Hydrostatic head : 45 inches H₂O (AATCC 127)

The material handles 1.5 lbf/in tension at room temperature. It starts stretching above 175°F (79°C). It melts at 275°F (135°C).

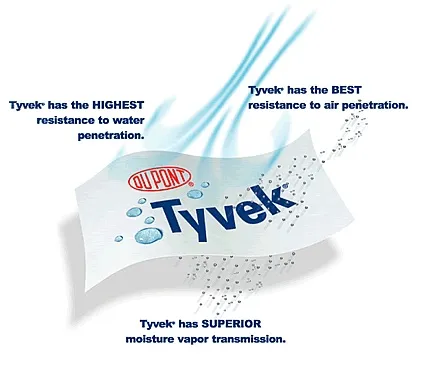

Particle Barrier Excellence

Tyvek’s continuous fiber structure blocks particles down to 1.0 micrometers. This makes it effective against dry particles and asbestos fibers. Microporous films break down with wear and tear. Tyvek keeps protecting throughout its service life. The continuous filaments create minimal lint. This matters for pharmaceutical cleanrooms and electronics manufacturing.

Surface resistivity stays below 2.5 × 10⁹ ohms at 23°C and 25% relative humidity ( EN 1149-1 ). This stops static charges that could ignite flammable atmospheres. The material also gets a Class 1 flammability rating (16 CFR 1610). It meets industrial safety garment fire resistance standards.

KleenGuard Disposable Coverall Material Technology and Protection Features

Kimberly-Clark built KleenGuard with microporous film lamination technology. This design focuses on liquid barrier performance. Tyvek, by contrast, targets particle protection. The product line breaks into different tiers. Each tier matches specific hazard needs with different materials.

KleenGuard A40 and A45 form the core chemical-resistant coveralls lineup. These suits pair microporous film with nonwoven fabric. The microporous film packs billions of tiny pores per square inch. Each pore runs 0.2-2.0 micrometers. Water vapor escapes through these pores. This gives you breathability. At the same time, they block liquid drops and particles above 1.0 micrometers. You get better liquid protection than Tyvek’s spunbond polyethylene.

Multi-Tier Material Design

KleenGuard adapts materials to fit protection needs:

A20 Disposable Coverall Series uses a five-layer SMMMS build (spunmelt/meltblown/meltblown/meltblown/spunmelt). The triple meltblown core creates winding paths for particles. Harmful dust hits multiple filter layers. The seamless front panel cuts out weak spots where the main exposure happens.

A30 Disposable Coverall Series uses three-layer SMS fabric (spunbond/meltblown/spunbond). This lighter build boosts air flow. Hot environment workers get better moisture release. The single meltblown layer still blocks dry particles well.

A80 Disposable Coverall Series steps up to Saranex 23-P film lamination. This chemical-resistant film bonds to a strong fabric backing. The mix fights off harsh chemicals. It handles jet liquid spray too. Standard microporous films can’t do this.

Protection Standards and Certifications

KleenGuard suits meet NFPA 99 rules for antistatic properties. This covers A30, A40, and A45 models. Surface resistivity stops static discharge in pharma and electronics work. The A40/A45 microporous barrier meets Type 5 and Type 6 coveralls standards. Type 5 means protection from airborne solid particles. Type 6 means resistance to light liquid splash.

Reflex design adds elastic at cuffs, wrists, and ankles. This seals tight in dusty cleanup zones, pesticide areas, and decon work. Low-lint build fits cleanroom rules. The cloth-like feel (especially in A80) cuts skin irritation during long wear times.

Disposable Coverall Price Analysis: Unit Cost vs. Real Value

Don’t just look at the sticker price when you budget for disposable coverall suits. Check the Total Cost of Ownership (TCO) instead. A small $0.24 gap might seem tiny. But it adds up. For a mid-sized shop that misses over $2,400 a year. You have to count storage, trash fees, and how many suits you actually use.

Market Prices

KleenGuard A40 usually costs 40-50% less than Tyvek 400. You get similar protection levels (Type 5/6) with both.

-

Tyvek 400: Costs $4.50 (bulk) to $12.00 (store prices).

-

KleenGuard A40: Costs $2.20 (bulk) to $6.50 (store prices).

Say you order 5,000 disposable coverall suits a year. Pick KleenGuard, and you save $10,000–$15,000 right away.

Hidden Costs

But the cheapest disposable coverall suit isn’t always the best deal. How you use them changes the math:

-

Durability (Tyvek Wins): Tyvek resists tears well. Rough jobs might need 1.5 KleenGuard suits to do the work of one Tyvek suit. This wipes out your savings.

-

Productivity (KleenGuard Wins): KleenGuard breathes better. It keeps the heat down. In hot spots (>85°F), workers take fewer breaks. This gives you 15-20% more work time.

-

Waste Management: KleenGuard materials weigh about 30% less than Tyvek. This lowers trash bills if you toss out a lot of them.

Buying in Bulk

Don’t pay the full list price. Sellers give discounts based on how much you buy:

-

100-500 units: Look for 15-25% off.

-

2,500+ units: Ask for 40-50% off. Sign a yearly contract.

-

10,000+ units: You get custom prices. These often hit 60% off.

The Verdict: Need toughness in rough zones? Tyvek costs more, but it lasts longer. For normal protection or hot places, KleenGuard gives you better value.

Application Scenarios: Which Disposable Coverall for Your Industry

Don’t simply default to one disposable coverall brand . Match the material to your specific industry hazards and budget constraints. Here is the breakdown:

Cleanroom & Pharmaceutical: Tyvek Wins

Tyvek is the clear standard here. Its continuous filament structure sheds virtually no lint, which is critical for preventing product contamination. Unlike microporous films that can degrade and shed, Tyvek offers a consistent barrier against particles down to 0.5 micrometers. For sterile processing or electronics manufacturing, the premium price is worth it to avoid costly defect rates.

Food Processing & Audits: KleenGuard Wins

KleenGuard dominates in value. For non-hazardous tasks like visitor audits or general hygiene checks, KleenGuard coverall suits ($1-2/unit) offer significant savings over Tyvek. The breathable material prevents heat stress during facility tours, and since disposable coverall suits eliminate laundry cross-contamination risks, they are often the smarter financial choice for food facilities.

Painting & Spraying: It Depends

Professional body shops should stick to Tyvek. Its Type 6B splash resistance blocks 95% of paint particles, directly reducing finish defects. However, for DIY projects or general maintenance, KleenGuard is sufficient. It costs about half as much and handles basic overspray well enough for non-critical finish work.

Warehousing & Construction: Mixed Usage

In high-turnover logistics, KleenGuard’s superior breathability (4x better than Tyvek) keeps workers more efficient in hot warehouses. However, for construction involving silica dust or sharp debris, you need Tyvek’s abrasion resistance. If you are just handling drywall dust? Switch to KleenGuard to cut costs by 35%.

High-Risk Chemical Zones: Neither

Be careful here. Neither standard Tyvek nor KleenGuard usually provides Type 3 protection against jet liquid sprays or full asbestos encapsulation. For these severe hazards, you must upgrade to specialized gear like Lakeland ChemMax. Standard disposables will fail too quickly in these environments.

Your industry picks which disposable coverall works best. Pharmaceutical cleanrooms need different features than construction sites or paint booths. Match the material to your actual hazards and work constraints.

Disposable Coverall Durability and Comfort: Long-Term Wear Performance

Real jobs need disposable work coveralls that handle specific bending and stretching without breaking. You must balance durability with breathability. This balance often decides the real cost of protection.

Material Fatigue and Durability

Tyvek 400 works great in high-stress spots. Its strong fiber structure handles over 500 rubs. You often get about 4 full shifts from it in industrial settings without failure. The material is torn. So, small punctures don’t spread into large rips.

But KleenGuard A40/A45 uses a different film that gets tired faster. Tiny tears can show up after 200-300 rubs. This can cause failure rates 30-40% higher than Tyvek in active jobs like painting or climbing. The lighter A30 series gives up even more strength. It fits best for short, light tasks.

Breathability and Heat Stress

Tyvek does well in moderate heat (65-75°F). But KleenGuard wins in hot spots (>85°F). Its tech lets 40-50% more moisture escape. This cuts down the “sauna effect” big time.

Data shows workers in hot warehouses have 35% fewer heat complaints with KleenGuard. They also take 15% fewer cooling breaks. In these places, better airflow beats Tyvek’s durability. You improve productivity.

Fit Retention and Cost Analysis

Wear them long-term, and you see differences in shape. Tyvek keeps its form well over many days. KleenGuard tends to stretch and sag (8-12% size change) because of the material type. But KleenGuard breathes better. So, you get less skin irritation over long periods.

Job intensity drives cost. In rough jobs, Tyvek is often cheaper per shift. One suit lasts longer than several KleenGuard units. On the flip side, KleenGuard offers better value for light or hot tasks. It keeps workers cool and comfortable. Track your failure rates and heat issues. This helps you find the best value for your site.

How to Choose Disposable Coverall(Tyvek vs KleenGuard)?

Buying disposable protective coveralls involves the safety, operations, and finance teams. They often have different goals. You need a set plan. This balances safety needs with your budget.

Step 1: Map Your Real Hazards First

Look at documented risks first, not product features. Companies often overspend on premium Type 4 suits. Often, a Type 6 splash barrier works fine. Make a simple risk matrix. Classify zones from “High Risk” (like asbestos) to “Low Risk” (visitor areas). Match the certification to the real hazard. Why pay for protection you don’t need?

Step 2: Calculate Total Ownership Cost

Unit price often lies. Look at the Total Cost of Ownership (TCO) instead. Use this weighted method:

-

Durability: A Tyvek suit lasts four shifts. A cheaper KleenGuard suit tears daily. The “expensive” option actually costs less per use.

-

Productivity: Heat stress kills efficiency. Breathable suits cut break frequency by 20%. You save thousands in labor time.

-

Volume Leverage: Stop buying case-by-case. Sign annual contracts for 2,500+ units. You get 30-50% off retail prices.

Step 3: Run a 90-Day Pilot Test

Don’t buy thousands of units based on a spec sheet. Test 100 suits from your top choices first. Track the numbers: failure rates (mid-shift tears), comfort scores, and heat breaks. Define success clearly. Let field data decide, not the salesperson.

Step 4: Verify Supplier Reliability

Vendor stability matters just as much as the product. Check their stock. Can they ship 2,000 units in 48 hours during a shortage? Look at their price history and support. A cheap supplier might disappear during an emergency. That creates a huge risk.

Step 5: Use a Data-Driven Scorecard

Stop guessing. Use a weighted scorecard. Rank Hazard Protection (35%), Total Cost (25%), Comfort (20%), and Reliability (15%). Math gets everyone on the same page. It speeds up approvals, too. Standardize the process. You likely see ROI within three months.

Certification and Compliance: Meeting Industry Safety Standards

Both Tyvek and KleenGuard meet core PPE coverall ratings required across industries. Certification alone doesn’t guarantee compliance. Your selection must match documented workplace hazards. It must also align with regional safety rules.

ISO 45001 sets the global standard for occupational health and safety management. This framework makes EHS compliance easier across multiple regions. Companies with global operations use ISO 45001 to unify their protective equipment standards. Both disposable coverall brands support this certification. You need to match them to your risk assessment first.

OSHA standards dominate US workplace safety requirements. The construction sector leads protective equipment investment at 28% market share. High-risk environments drive strict compliance needs. These include heavy machinery zones, elevated work areas, and chemical storage. OSHA requires written safety programs. You must review them each year. Your disposable coverall choice must align with these documented protocols.

Fortune 500 companies prioritize compliance. 90% require safety standard updates every three months. This frequent review cycle catches regulatory changes before audits. Real-time tracking systems verify that workers use certified protective gear in designated hazard zones.

Compliance Verification in Practice

Check these factors when selecting industrial safety garments:

-

Centralized incident tracking : Your EHS system should log every disposable coverall failure or breakthrough incident. This data shows whether your current protection level matches actual hazards.

-

Automated compliance reminders : Set alerts for certification renewals and regulatory updates. 76% of safety managers prefer digital systems that flag expiring certifications on their own.

-

Customizable audit reports : Generate reports showing Type 5/6 coverage rates, suit replacement frequency, and worker training completion. Auditors want this data formatted for quick review.

Safety training investment pays measurable returns. Companies see a $4.20 return for every $1 spent on compliance programs. This comes through 43% fewer workplace accidents and 25% lower insurance premiums. Insufficient training causes 50% of workplace injuries. Your disposable coverall selection means nothing without proper training. Workers must understand correct donning, doffing, and disposal procedures.

The global safety training market will hit $12.4 billion by 2025. Growth runs at 7.2% each year. 45% of companies are increasing safety budgets in 2025. This surge reflects tightening regulations and rising liability costs. Investing in certified particle barrier clothing now prevents expensive compliance gaps later.

Tyvek vs KleenGuard Disposable Coverall: Quick Decision Matrix

|

Your Priority |

Recommended Choice |

|---|---|

|

Maximum particle protection + cleanroom compliance |

Tyvek 400 |

|

Cost savings on 2,500+ units per year |

KleenGuard A40/A45 |

|

Hot environment work (85°F+) |

KleenGuard A40/A45 |

|

High-abrasion tasks (construction, demolition) |

|

|

Light chemical splash + breathability |

KleenGuard A40/A45 |

|

Pharma/electronics making |

Tyvek 400 |

|

Food processing + visitor audits |

KleenGuard A30/A40 |

|

Multi-hour shifts with minimal breaks |

Tyvek 400 |

Conclusion

Choosing the winner depends entirely on your specific job site. Tyvek offers unbeatable durability for rough cleanups, while KleenGuard provides breathable comfort and better value for hot environments. Don’t guess when it comes to safety. If you need help selecting materials or want a quote for custom disposable coveralls , reach out to our team today for expert support.