Ensuring your N95 mask fits properly is essential for real protection. A tight seal prevents airborne particles from entering and keeps you safe. N95 mask fit testing confirms the exact brand, model, and size that suits your face. Without a proper fit, even an N95 that filters 95% of particles cannot protect you effectively. Annual testing, seal checks, and proper PPE pairing maximize safety.

Why N95 Mask Fit Testing Matters?

Many workers assume that wearing an N95 respirator is enough. But even minor leaks drastically reduce protection. In healthcare, a study showed that 73% of workers failed at least one fit test during simulated chest compressions. Another audit found a 43% false negative rate when fit testing shortcuts were taken.

Fit testing is about more than just legal compliance; it ensures real-world protection. Combining a fit-tested N95 mask with other PPE, such as disposable coveralls, hoods, and face shields, creates a complete protective barrier. Proper training, consistent seal checks, and annual testing are key to maintaining safety.

OSHA N95 Mask Fit Testing Requirements and Rules

OSHA’s Respiratory Protection Standard (29 CFR 1910.134) requires N95 mask fit testing in these situations:

– Before workers use them for the first time

– When a different mask style, size, model, or make is chosen

– At least once a year after that

This rule applies to all workplaces that need respirators for worker safety. Healthcare and skilled nursing facilities must follow it.

Written Respiratory Protection Program

Employers must create a written respiratory protection program.

They must put this program into action.

The program should cover procedures specific to your worksite. This includes selection and care of N95 respirators, fit testing, and training.

Fit testing proves that an N95 forms a tight seal on the worker’s face. This limits the risk of airborne contaminants. I recommend this step because it’s critical against threats like COVID-19 and influenza.

Medical Clearance Before N95 Mask Fit Testing

Employees must complete a medical evaluation before fit testing or wearing any respirator.

This medical clearance uses the OSHA questionnaire in Appendix C. A healthcare professional reviews it. The information stays confidential.

Re-evaluation is needed if there is a health status change. You don’t need to repeat the initial clearance every year unless something changes.

NIOSH Certification and CMS Standards

NIOSH-certified N95 respirators are approved for worker protection under these requirements. Surgical masks and “KN95s” don’t meet this standard.

Skilled nursing facilities must follow Ftag 880 (CMS Infection Prevention and Control Practices). This recognizes OSHA’s rules as national standards.

Fit Testing Protocols and Qualified Testers

Qualified professionals must perform or supervise every fit test.

You can conduct fit testing in-house. You can also use external providers. N95 manufacturers and suppliers offer fit testing resources and materials.

Quantitative fit testing requires specific equipment. For example, a TSI 8038 or 8048 Portacount. These use CNC (Condensation Nuclei Counter) or CNP (Controlled Negative Pressure) methods for precise results.

How to Prepare for an N95 Mask Fit Testing?

Immediate Preparations

Hand Hygiene: Wash your hands well before you touch the respirator. This prevents contamination.

Facial Preparation: Remove all facial hair that could break the seal. No beards, mustaches, or stubble along the sealing line. Take off glasses and jewelry that may interfere with the fit. I recommend a clean-shaven face for a valid test.

No Eating/Drinking/Smoking: Don’t eat food, chew gum, drink flavored drinks, or use tobacco for at least 15 minutes before testing. This helps you detect fit test solutions.

Medical Clearance: Complete a medical evaluation in advance. Document it. OSHA requires this to confirm you can wear a respirator without health risks.

ID and Equipment: Bring your employee ID. Have your assigned respirator ready (make, model, and size). I suggest bringing backup options if the first one doesn’t fit well.

Respirator and PPE Setup

Correct Respirator: Use the exact M95 respirator you’ll wear on the job for fit testing. Match the make, model, and size.

Fit Check: Put on the respirator the right way. Center it over your chin. Adjust the straps—not too tight. Mold the nose clip. Check for slippage. Do a seal check as the manufacturer describes.

Check Other PPE: Will you wear a disposable coverall , hood, or other PPE at work? Put them on during the fit test. Make sure straps or edges don’t affect the mask’s seal. I recommend you simulate how you’ll wear all PPE during your shift.

Test Environment: Use a clean, quiet, well-lit room with a mirror. Have all fit test equipment ready (hood, nebulizer, solutions). Check that everything is in good condition.

How to Do N95 Mask Fit Testing?

Qualitative vs. Quantitative N95 Mask Fit Testing: Key Methods

– Qualitative fit testing (QLFT) uses your senses. You taste or smell a test agent like saccharin or Bitrex. If it leaks into the mask, you’ll know. This is a simple pass/fail check. Many facilities use it for N95s when equipment is limited.

– Quantitative fit testing (QNFT) uses instruments like PortaCount™. The machine measures the exact amount of leakage. It calculates a numerical fit factor. I recommend this method for precise results. It’s also useful when you can’t use qualitative agents.

Quantitative methods have a higher pass rate. They’re more reliable. I suggest using them in healthcare environments.

How to Run a Qualitative N95 Mask Fit Testing with Coveralls?

Sensitivity Screening: First, confirm the user can detect the test substance. For example, they should taste Bitrex or saccharin without the respirator.

Don PPE: Put on the N95 respirator. Add any PPE worn during patient care. This includes disposable coveralls and hoods.

Seal Check: Do a positive/negative pressure seal check. Fix any leaks before you continue.

Position the Testing Hood: Place the hood over the user’s head and shoulders. Make sure the hood doesn’t press on the respirator seal. It shouldn’t shift the seal either.

Spray the Test Agent: Spray the test solution into the hood. Increase concentration if needed.

Conduct Fit Test Exercises:

Normal breathing

Deep breathing

Turn head side-to-side

Move your head up and down

Speak loudly/read a passage

Bend over

Return to normal breathing

Pass/Fail: The user shouldn’t taste or smell anything. If they don’t, the mask passes. If they do, it failed.

Failed Test: Try a different disposable mask model or size. Restart the process.

How to Run a Quantitative N95 Mask Fit Testing with Coveralls?

Don Complete PPE: Put on the N95 mask, disposable coverall, and hood. This simulates actual job conditions.

Seal Check: Check the respirator seal. Use positive/negative pressure.

Set up Instrumentation: Attach the sampling port to the mask. Connect it to the PortaCount™ or similar tester.

Sample Measurement: The machine measures particle concentration. It checks inside and outside the mask. Then it calculates the fit factor.

Repeat Fit Test Exercises: Do the same head movements. Include talking and bending exercises.

Pass/Fail Criteria: For N95s, you need a fit factor of 100 or greater. Below 100 means the fit is poor.

Failed Test: Select a new mask model or size. Repeat the test.

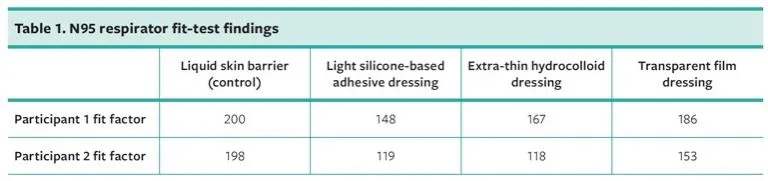

Data and Real-World Examples

Fit factor pass threshold: N95 = 100+; full-face = 500+.

Fit failures are common: 73% of healthcare workers failed at least one fit test during simulated chest compressions. 18% had issues like strap slippage.

Real-use simulation matters: Based on my experience, I’ve seen how real work affects fit. In a study with 120 nursing students, fit factors dropped after real work activity. 33% no longer passed. This proves the importance of full PPE testing.

PPE affects fit: Always test with the coverall or hood in place. They can change seal integrity.

If the Fit Test Fails

Stop using the failed mask right away.

Try a different size or model. Retest.

Do not enter hazardous environments. You must confirm a passing fit for the specific combination of mask and PPE.

Best Practices and Documentation

Documentation is required: Record the respirator brand, size, and hours worn. Include fit test results per user. Keep detailed records.

User training is critical: Educate users on how to put on, remove, and fit-check their N95s. I suggest hands-on training sessions. Even a perfect test doesn’t protect you if you wear it wrong.

Retest often: Annual fit testing is required as a minimum. Re-test after any changes to facial structure. This includes significant weight shifts or dental surgery. Also, retest when changing mask models or sizes.

Pro tip: Clean hoods and nebulizers between uses. This prevents cross-contamination. I recommend archiving individual taste sensitivity and test data. Follow structured checklists. These steps keep users safe.

How to Read N95 Mask Fit Test Results and Stay Compliant?

I recommend understanding fit test results for proper respiratory protection. This also helps you meet rules and regulations. Below, I explain what to look for, how to document, and key maintenance steps for N95 respirators and disposable coveralls.

How to Read Pass/Fail Results and Fit Factor?

Fit Factor Explained: The fit factor shows how tight the mask seals. You calculate it by dividing the particle count outside the mask by the count inside during testing.

- Example: 10,000 particles/cm³ outside and 100/cm³ inside gives a fit factor of 100.

OSHA Pass/Fail Standard: For N95 ( half-mask ) respirators, a fit factor of 100 or higher means pass.

- Pass: Fit factor ≥ 100 (readings like 150 or 220 = pass)

- Fail: Fit factor < 100 (readings like 80 or lower = fail; you need action)

Fail Action: If the test fails, check the mask fit. Remove facial hair and test again. If it still fails, try a different model, brand, or size.

Tell the Wearer Right Away: You must notify the wearer of the result at once. Those who pass get that specific respirator for work.

What to Document for N95 Mask Fit Testing?

What to Record: I suggest you document each fit test with:

– Respirator brand, model, and size

– Date of test

– Name of fit tester

– Result (pass/fail + fit factor)

– Any notes (adjustments, facial hair, retests, etc.)

Legal Records: Store fit test records for the worker’s employment period, plus at least 30 years.

Sample Record:

Date: 2025-10-15 Respirator: 3M 1860, Size Regular Tester: Jane Smith Result: Pass, Fit Factor 220 Remarks: User clean-shaven, no adjustments needed

Ongoing PPE Maintenance and Inspection

For N95 Respirators:

Check before every use: Look for damaged straps, tears, or a bent nose piece. Never use a damaged mask.

Storage: Store in a clean, dry area free from contamination. Keep away from sunlight or extreme heat.

Replacement: Replace disposable face masks after one use or if they get damaged or dirty. Follow adjusted protocols during shortages. But never reuse a mask that looks compromised.

For Disposable Coveralls:

Inspect each time: Watch for tears, punctures, or contamination before use.

Disposal: Discard used coveralls as hazardous waste. Never reuse them.

Keep a PPE Log: Record inspections, replacements, and any issues.

Repeating the Fit Test

New Respirator Model: A change in mask brand , model, or size means you need a new fit test.

Physical Changes: Re-test if there’s a big change in facial shape or weight. Also, retest after dental or facial surgery.

Test Each Year: Everyone must repeat fit testing at least once per year. This applies regardless of other changes.

Example: Moving from a 3M 1860 (Regular) to a Moldex 2200 (Large) due to low stock requires a repeat fit test.

Tips and Best Practices I Recommend

Train Your Staff Well: Train all staff on how to put on, check, and remove respirators. I emphasize that seal checks each day are important. But they do not replace a formal fit test.

Comfort and Fit: Choose respirators that feel comfortable. This improves compliance.

Use a Mirror: I suggest using a mirror to check for correct placement.

Facial Hair Policy: Requires the removal of facial hair that could break the mask’s seal.

Schedule Rotations: Rotate fit testing across all staff. This ensures ongoing compliance and readiness.

Common N95 Mask Fit Testing Mistakes and How to Avoid Them

Facial Hair, Accessories, and the Mask Seal

Facial hair—like beards and mustaches—creates leaks around N95 respirators. Even a small amount of hair growth can break the mask’s seal. This leaves you open to airborne contaminants. OSHA standards are clear: tight-fitting masks won’t protect you if facial hair or jewelry breaks the seal area.

If you must keep facial hair, consider mask fit adaptors. But know they may not guarantee protection. I recommend clean-shaven faces along the seal line before testing. Workers should shave every day they wear the mask.

Not Testing with All PPE in Place

Here’s a major error: N95 Mask Fit Testing without real-world PPE conditions. You test the mask alone. But on the job, you wear hoods, face shields, or coveralls. This creates a poor fit.

Always conduct the fit test with all PPE combinations workers will wear. I suggest you test with the exact gear they use daily. Failing to do this means the seal could break during work. Your real protection drops fast.

Skipping Real Fit Test Protocols

Another common mistake is skipping the actual fit test routines. I’m talking about the movement and breathing exercises. Just wearing a mask and assuming it protects you isn’t enough.

OSHA requires fit tests. Workers must talk, move, bend, and breathe hard while exposed to saccharin or Bitrex. Always perform both positive and negative pressure seal checks. Don’t just do this during annual fit testing. I recommend doing it every time you put on a mask.

Beta Error Rates in N95 Mask Fit Testing Methods

Be aware of beta errors. These are cases where workers pass fit tests but shouldn’t. Data reveals:

– 8% beta error for Bitrex and saccharin methods

– 9% for TSI PortaCount Plus

– Errors jump to 19% if three attempts per model are allowed before switching models

Results are worse for elastomeric respirators (14–21% error) than disposable N95s (≤5% error). In practice, about one in five workers may be deemed protected but aren’t. This happens if you don’t follow protocols with care.

Overusing or Reusing Respirators

Using N95s beyond their intended lifespan reduces both fit and filtration. Wear and reuse break down nose pieces and straps. This makes a good seal impossible.

I suggest you discard masks after the recommended use. Never reuse a mask if the physical integrity is damaged.

Neglecting Retesting After Face or Health Changes

Changes in facial structure require immediate retesting. I’m talking about weight gain, weight loss, surgery, or dental work. Skipping this can cause a failed seal. The mask may have fit before, but doesn’t now.

Based on my experience, you should monitor staff for conditions that need retesting. Check them often.

Failing to Document and Retest

OSHA mandates annual fit testing and clear documentation. Keep records of:

– Test date and method

– Respirator type, model, and size

– Tester’s name

– Pass/fail results

Retest after any model change, physical change, or worksite condition change. No documentation? You are out of compliance. You risk OSHA penalties.

N95 Mask Fit Testing FAQ: Common Questions and Practical Guidance

I want to help you understand N95 fit testing better. Here are clear answers to common questions, based on expert insight and real procedures.

What Happens If You Fail an N95 Fit Test?

Failing a fit test shows your N95 mask does not seal well. This reduces protection against airborne hazards.

Steps to take:

- Try different mask sizes or models until you get a good fit.

- Check your donning technique. Sometimes you wear the mask wrong, which causes leaks.

- Use a mask fitter if you can get one. It helps create a better seal.

Key point : Fix any fit issues right away to stay safe at work.

How Often Should You Do the N95 Mask Fit Testing?

Once a year: Most workplaces require fit testing every year.

After changes: Switch to a new mask model or size? You must do another fit test.

Physical changes: Big changes in your weight, dental work, or face shape mean you need retesting.

Can You Do N95 Mask Fit Testing While Wearing a Disposable Coverall Hood?

Yes. I recommend you do the N95 mask fit test with your regular full protective gear. Include disposable coverall hoods if you wear them during actual job duties.

This makes sure your mask works under real conditions at work.

Does Passing a N95 Mask Fit Testing Guarantee There Will Never Be Leaks?

A fit test cuts down the leak risk a lot. But it is not a permanent guarantee.

You should check the mask seal every time you put on the respirator. Do seal checks each day you wear it.

Can You Reuse the Same Mask That Passed a N95 Mask Fit Testing?

Yes. But your disposable mask manufacturer or employer’s guidance must allow it. Also, the mask must stay undamaged and clean.

Do a seal check each time you reuse the mask.

Putting on and taking off the mask wears it out. Replace it if the fit or structure changes.

Conclusion

Proper N95 mask fit testing ensures real protection and regulatory compliance. Always use the correct model and size, retest annually or after facial changes, and pair with disposable coveralls when needed. Document every step, train staff, and follow OSHA standards. A fit-tested N95 mask with appropriate PPE is the best defense against airborne hazards, from viruses to industrial particles.