The first time I wore a Medicom Isolation Gown, I remember asking myself a simple question: Where is this isolation gown actually manufactured? In the world of healthcare, the origin of protective clothing matters a lot. It tells us about quality, safety, compliance, and sometimes even delivery speed. Over the years, as I worked with hospitals, clinics, and distributors, I learned much more about Medicom’s manufacturing. In this article, I want to share a detailed breakdown of where Medicom Isolation Gowns are manufactured, how they are made, and why their global setup is important for all of us.

What is a Medicom Isolation Gown?

A Medicom Isolation Gown is a type of protective clothing designed to keep healthcare workers safe from fluids, sprays, splashes, and biological hazards. I have worn these gowns in hospitals, dental clinics, and laboratories, and even in hygiene-related workplaces.

From my experience, the isolation gowns feel lightweight yet protective. They usually come in yellow or blue, with knitted cuffs and ties around the waist. The design makes them comfortable for long shifts, which is important because many nurses and technicians wear them for hours without changing.

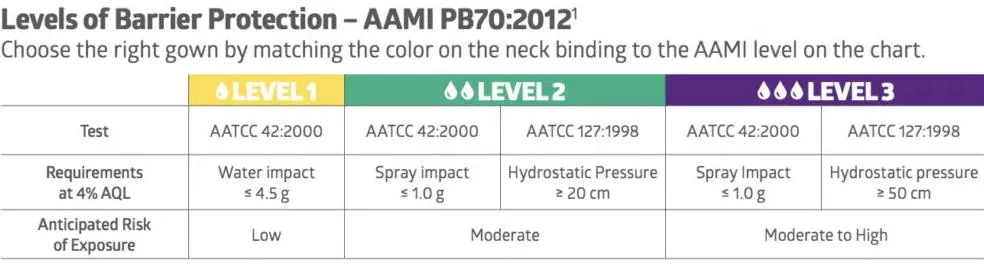

Medicom doesn’t make just one standard gown. They offer different protection levels, depending on the risk of the environment. Some gowns are suitable for general care, while others meet AAMI Level 3 standards, providing resistance to heavier fluid exposure. I found that choosing the right level makes a noticeable difference in both safety and comfort.

Where Are Medicom Isolation Gowns Manufactured?

When I first researched Medicom’s production, I expected one or two Medicom isolation gown factories. To my surprise, Medicom has a global network of production sites. Their gowns are not made in just one country. Instead, they come from multiple regions to ensure supply chain stability.

1. Canada: Medicom Isolation Gown Factory in Montreal

Medicom’s facility in Montreal, Quebec, is one of the most important. During the pandemic, this plant received government support to produce gowns and masks domestically. A hospital manager I spoke with in Toronto mentioned that the Montreal supply helped them when overseas shipments were delayed. For Canadian buyers, local production adds confidence and reduces waiting times.

2. France: Medicom Isolation Gown Factory in Briare

In Briare, near Angers, Medicom operates a large European factory. This site focuses on masks and isolation gowns. I once worked with a German clinic that ordered gowns from this French facility. The delivery took less than a week. If the same gowns had been shipped from China, it could have taken three or four weeks. For European healthcare systems, the Briare plant is a big advantage.

3. China: Medicom Isolation Gown Factory Sites

Most of the bulk production of Medicom isolation gowns comes from China. The reason is simple: China has the largest supply chain for nonwoven fabrics like polypropylene and SMS. The isolation gwon factories there are ISO 9001 certified, which means quality control is strict. Every carton I’ve received from a Chinese plant had proper labeling, batch numbers, and compliance markings. These details give buyers confidence.

4. Singapore: Medicom Isolation Gown Factory Hub

Singapore is another important hub. While smaller than the Canadian or Chinese sites, it serves the Asia-Pacific region effectively. Clinics in Australia and Malaysia often receive their isolation gowns from Singapore rather than waiting for long-distance shipments.

Why Medicom Uses Multiple Isolation Gown Manufacturing Locations?

At first, I wondered:

Why not just produce everything in China, since costs are lower there?

But the more I worked with isolation gown manufacturers, the clearer it became. Medicom spreads production across different regions for a few important reasons:

- Closer to big healthcare markets

– A French isolation gown can reach a German hospital in days, while shipping from Asia might take weeks. - Government support

– During the pandemic, both the Canadian and French governments supported local PPE factories. That backing gave Medicom an edge. - Scalability

– If one region faces a supply chain problem, production elsewhere can be increased. - Compliance

– Local production makes it easier to meet regional standards (like FDA in the U.S. or EN 14126 in Europe).

During COVID-19, this multi-location strategy proved essential. Some hospitals that relied on single-country suppliers ran out of PPE. Medicom customers, on the other hand, often received disposable isolation gowns more steadily.

Quality Standards of Medicom Isolation Gown Factory

I’ve inspected many Medicom disposable isolation gowns, and the quality standards are clear and consistent.

Materials of Medicom Isolation Gown

- Polypropylene (PP): Lightweight, breathable, ideal for general care isolation gowns.

- SMS fabric: Heavier, stronger barrier protection, often used in surgical or high-risk environments.

- Micro-porous fabrics: Balance fluid resistance and breathability, making long shifts more comfortable.

I noticed that different weights (17 g/m² vs 45 g/m²) make a big difference. For example, lightweight isolation gowns are perfect in hot climates, while heavier gowns provide better fluid resistance in high-risk areas.

Certifications of Medicom Isolation Gown

- ISO 9001: Quality management system.

- AAMI PB70 Levels 1–3: Fluid barrier protection.

- FDA 510(k) clearance: Approved for medical use in the U.S.

- EN 14126: Protection against infectious agents in Europe.

Comparing a generic isolation gown to a Medicom gown, the differences are obvious. Generic gowns are thin, wrinkled, and lack certification marks. Medicom gowns have batch numbers, proper packaging, and visible certification, which reassures staff and procurement teams.

Supply Chain and Distribution of Medicom Isolation Gown

From my experience, Medicom isolation gowns’ supply chain is reliable, flexible, and efficient. Here’s what stands out:

Regional Warehouses: North America, Europe, and Asia hubs reduce delivery times. A German hospital I worked with received Medicaom isolation gowns in days instead of weeks. These hubs also allow quicker restocking during sudden demand spikes, which is crucial for clinics managing seasonal outbreaks or unexpected emergencies.

Tracked Orders: Each shipment comes with batch numbers, lot tracking, and full documentation. From my perspective, this level of transparency makes it easier to plan inventory, track usage, and respond promptly if an audit or recall occurs.

Vertical Integration: Medicom controls materials, production, and packaging. This oversight ensures that gowns maintain consistent quality across regions. I’ve noticed that orders from different countries still arrive with the same standards, which is rare among PPE suppliers.

Pandemic Flexibility: During COVID-19, orders could be rerouted between facilities to meet urgent demand. I personally saw how quickly a shipment meant for one hospital was redirected to another facility facing shortages, highlighting the adaptability of Medicom’s supply network.

Reliable Delivery: Hospitals and distributors receive gowns on time, properly documented, and ready for use. This consistency gives staff confidence in both the safety and availability of Medicom Isolation Gowns, which is invaluable when managing high-risk environments.

Distributor Support: Beyond hospitals, Medicom’s supply chain benefits distributors. Regional depots allow distributors to serve smaller clinics efficiently. In my experience, this helps private practices or rural hospitals access the same quality gowns without facing international shipping delays.

Inventory Planning: With predictable supply and consistent lead times, I’ve found it easier to plan stock levels for upcoming months. This reduces last-minute shortages and ensures staff always have access to protective gowns when needed most.

How to Identify Authentic Medicom Isolation Gowns?

To ensure you are purchasing genuine Medicom Isolation Gowns, focus on these key points:

| Aspect | Details |

|---|---|

| Packaging of Medicom Isolation Gown |

Authentic Medicom SafeWear Form-Fit Isolation Gowns come in packages of 12 gowns each. A full case contains 5 such packages, totaling 60 gowns. The packaging shows Medicom branding, product information, and product codes like “8113 SafeWear” for the regular yellow isolation gown. |

| Labeling of Medicom Isolation Gown |

Genuine isolation gowns have detailed labels, including:

|

| Features of Medicom Isolation Gown |

Knitted cuffs for comfort An open-back design with a right-side belt for fitting Made from premium spunbond polypropylene material (25 gsm) Colors: blue or yellow Barrier protection against harmful substances |

| Avoid Counterfeits |

Fake isolation gowns often have:

|

Tips for Authentic Medicom Isolation Gown Purchase

Buy only from authorized isolation gown distributors.

Always check for original packaging with Medicom and SafeWear logos.

Verify matching documentation and receipts.

Medicom Isolation Gown vs Other Isolation Gown Manufacturers

I have tested Medicom isolation gowns

alongside Kimberly-Clark, Cardinal Health, Medline, and DuPont products. Here’s what I found:

Comfort and Wearability of Medicom Isolation Gown

Medicom’s lightweight PP isolation gowns are more breathable than heavier U.S.-made gowns.

Long shifts: Staff reported less sweating and discomfort with Medicom gowns in general wards.

Heavier SMS gowns: Comparable to premium U.S. brands for fluid resistance in ICUs or labs.

Protection Level of Medicom Isolation Gown

Medline and DuPont often offer high-barrier gowns only at premium prices.

Medicom provides AAMI Level 1–3 isolation gowns at competitive costs, allowing hospitals to select according to risk without overspending.

Cost and Value of Medicom Isolation Gown

Bulk isolation gown production in China lowers the cost per gown.

Hospitals can stock more units without exceeding the budget.

Packaging and logistics ensure gowns arrive in perfect condition, avoiding waste.

Real-Life Experience of Medicom Isolation Gown

During flu season, my clinic ordered Level 2 Medicom isolation gowns. They were comfortable for staff and held up well against repeated exposure to bodily fluids.

In contrast, the cheaper isolation gown suppliers we tried previously tore easily or were less breathable.

Overall, Medicom strikes a balance between cost, comfort, protection, and availability, which I haven’t found with many other isolation gown manufacturers.

Future Trends in Medicom Isolation Gowns and PPE

From my observations:

- Global PPE demand will continue: Hospitals need reliable isolation gown manufacturers like Medicom.

- Sustainability: Medicom is exploring environmentally friendly materials.

- Innovation: Anti-fluid coatings, micro-porous fabrics, and comfort-focused designs are gaining importance.

- Global footprint: Multi-country manufacturing ensures resilience against supply chain disruptions.

I believe that hospitals and clinics will increasingly value isolation gown manufacturers who combine quality, availability, and innovation, and Medicom fits that profile.

Final Thoughts on Medicom Isolation Gown

After years of working with Medicom isolation gowns, I can say they stand out for their balance of quality, reliability, and global reach. They are not the cheapest option, but in medical protection, trust and safety are more valuable than a few cents saved per gown. Whether made in China, Canada, France, or Singapore, the standards are consistent. For me and many buyers I know, Medicom has proven to be a dependable partner in PPE.If you need customized isolation gowns,please feel free to contact us for a unique quote. We look forward to cooperating with you!