Buying a bad coverall can cost money and risk your safety. Tyvek disposable coveralls protect from dust, chemicals, and germs, but not all are equal. This guide shows how to choose the right one, what features matter, and tips to stay safe and comfortable at work.

What Are Tyvek Disposable Coveralls?

Tyvek disposable coveralls are light protective suits. DuPont makes them from flash-spun polyethylene fibers. I recommend these coveralls because they resist tears well and last long. They block liquids but still let air through. Based on my experience, they create a strong shield against dangerous dust, tiny particles, and chemicals. They protect you from particles as small as 1.0 microns.

Tyvek Disposable Coveralls vs Other Disposable Coverall Materials

I recommend understanding the differences between Tyvek and other materials before you buy. Polypropylene, SMS, and microporous film each serve different purposes. This knowledge helps you pick the right disposable coverall for your workplace safety and comfort needs.

| Feature | Tyvek | Polypropylene | SMS | Microporous Film |

|---|---|---|---|---|

| Particle Barrier | Excellent (>1 micron) | Basic (dust, fibers) | Good (dust, splash) | Good (fine, light splash) |

| Chemical Resistance | High | Minimal | Moderate | Moderate |

| Durability/ Abrasion | Excellent | Low | Moderate | Moderate |

| Breathability | Good | Excellent | Very good | Good |

| Comfort (Long Wear) | High | High | High | Moderate |

| Price Range (2025, USD) | $7–$14 | $2–$4 | $3–$8 | $4–$10 |

Typical Use Cases

- Tyvek: I recommend it for asbestos abatement, spray painting, lead remediation, pharmaceutical or food environments, and high-audit cleanrooms.

- Polypropylene/SMS: Best for dust, general cleaning, light maintenance, and non-hazardous food handling.

- Microporous: Use it for light chemical splash, forensics, and some medical tasks.

Workers say Tyvek gives them peace of mind. They see real safety improvements. They cite its solid barrier and comfort even under full PPE. Tyvek beats lower-cost coveralls in critical jobs.

Key Design Features and Benefits of Tyvek Disposable Coveralls

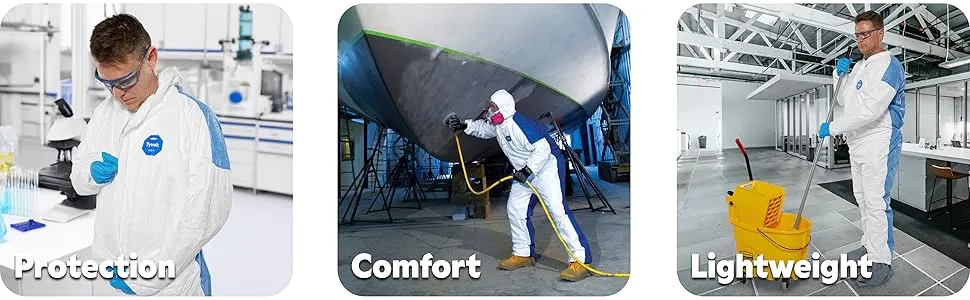

I recommend Tyvek disposable coveralls because they offer several design elements that boost safety and user experience. Based on my experience, these suits work well for various high-risk jobs.

Essential Structural Features

Hood Design: Most models include an attached, elastic hood. This gives full head and neck coverage. It fits tightly around respirators or masks. This reduces the chance of particles or splashes entering hazardous areas.

Elastic Cuffs and Ankles: Elastic at the wrists and ankles keeps the suit in place. This cuts down exposure points. It allows you to move freely. It also lowers the risk of particles or liquids getting inside the coverall.

High-Quality Zippers: Zippers are nonsparking. They come with protective storm flaps. These features make it easy to put on and take off the coverall. They maintain a sealed barrier. This matters in areas with repeated movement.

Sizing Options and Comfort Fit:

Tyvek suits come in sizes from Small up to 3X-Large or higher. The design allows freedom of movement. The comfort fit reduces the risk of tears. It suits a wide range of body types. This holds even during hard physical work.

Advanced Material Engineering

Continuous Barrier Protection: The material uses flash-spun high-density polyethylene. This creates a solid shield against particles as small as 1 micron. I’m talking about asbestos, mold spores, and fine dust. The coveralls stay light and flexible.

Breathability and Moisture Control: Micro-porous fibers let sweat and vapor escape. They don’t let in larger droplets or particles. Workers report less heat stress and fatigue during long shifts. This ventilation makes a real difference.

Tear and Abrasion Resistance:

Tyvek coverall suits keep their integrity after bending, squatting, or repeated abrasion. Users in construction and cleanup sites note that Tyvek resists snags. Basic polypropylene suits would tear in the same conditions.

Antistatic Treatments: Some models prevent static electricity. This adds safety in industries where sparks could create fire or explosion risks. I suggest these for chemical manufacturing or grain handling.

Common Configurations and Customization

Full-body options with attached hoods and boots give maximum coverage for hazardous jobs.

Features like thumb loops, multiple seam types (serged or taped), and high-visibility coloring help match the coveralls to specific workplace hazards.

Application-Specific Optimizations

- For tasks with big chemical splash risks, I recommend specialized models like Tychem or Tyvek 800. These go beyond standard protection.

- The lightweight design and ergonomic patterns make Tyvek my top choice for long shifts. They work great for demanding inspection and cleanup work. They reduce fatigue and maintain safety.

- Air sampling and real-world testing show that Tyvek offers superior containment of dangerous particles. This matters for industries like lead or asbestos removal, healthcare, pharmaceuticals, and food production.

I like Tyvek coveralls because professionals favor them for their protection, comfort, and durability. Real-world feedback and workplace audits show their value. They deliver breathable comfort and strict barrier protection against fine dust, chemicals, and biohazards.

Tyvek Disposable Coverall Types: Choosing the Right Model for Specific Hazards

I recommend that you understand the different Tyvek disposable coverall types before buying. This helps you get the right protection, comfort, and fit. Tyvek suits protect against many hazards. Three main series are used in workplace safety: Tyvek 400, Tyvek 500, and Tyvek 600.

Tyvek 400: Standard Protection for Dust and Light Splash

Best for: General protection against dust, asbestos fibers, light liquid splashes, and basic lab work.

Protection level:

Type 5 certified (protects from hazardous dust and particles).

Type 6 certified (protects from limited liquid splashes).

Design highlights:

Made of flash-spun high-density polyethylene.

Antistatic treated. It allows air and vapor to pass. This reduces heat stress.

Features elastic at the waist, wrists, ankles, and hood fit for respirator use.

Sizes range from SM to 4XL. It has reinforced stress zones for longer wear.

Real-world examples:

I suggest this coverall for asbestos abatement, paint shops, and basic building maintenance.

Tyvek 500: Enhanced Barrier for Dust and Liquid Sprays

Best for: Jobs needing both fine particle and liquid spray protection. Examples: food processing and pharmaceutical manufacturing.

Protection level:

Type 5 & 6 certified. Blocks particles ≥1 micron.

Certified for infectious agents ( EN 14126 ) and radioactive particles (EN 1073-2).

Material and performance:

Flash-spun HDPE, thickness of 140 μm.

Tear resistance 27 N, burst strength 345 kPa.

Hydrostatic head 48 inches H₂O for high liquid resistance.

Key features:

Stitched and taped seams.

Thumb loops for a tight glove seal.

Tunneled elastication for more secure cuffs and ankles.

Sizes from SM to 4XL with hoods and ergonomic fit for long-duration work.

Use cases:

Workers wear this in pharmaceutical plants and food processing lines. It prevents contamination from dust and splashes.

Tyvek 600: Maximum Protection for Chemicals and Biohazards

Best for: The highest risks. This includes chemical handling, biomanufacturing, healthcare, and emergency response to hazardous spills and infectious disease.

Protection level:

Type 4 certified (liquid spray).

Type 5 certified (particulates).

Type 6 certified.

Meets EN 14126 for infectious agents.

Enhanced hydrostatic resistance (>10 kPa).

Flexible in temperatures down to –73°C, melts at 135°C.

Performance stats:

41.5 g/m² basis weight.

Strong puncture resistance (>10 N).

Flex fatigue resistance (>100,000 cycles).

Design features:

Hooded for full face protection.

Stitched-and-taped seams, thumb loops, and tunneled elastication.

Glued waist, self-adhesive zipper with chin guard for a positive seal.

Ergonomic design supports a close fit across all sizes and body shapes.

Real-world application:

Chemical spill teams and infection control units in hospitals use this.

Quick Reference Table: Tyvek Coverall Types

| Model | Main Feature | Protection Level | Standards | Common Uses |

|---|---|---|---|---|

| Tyvek 200 | Lightweight | Dust | – | Cleaning, dry environments |

| Tyvek 400 | Standard | Dust + light liquid | Type 5, 6 | Asbestos, painting, labs |

| Tyvek 500 | Splash resistance | Dust + liquid spray | Type 5, 6 | Food, spraying, pharma, cleanrooms |

| Tyvek 600 | Highest protection | Dust+liquid+biohaz. | Type 4, 5, 6 | Chemicals, healthcare, biohazards |

In summary: I suggest you choose your Tyvek disposable coverall type based on the hazards you face. Also consider body fit needs and desired comfort level for the job. Tyvek 400 suits work well for standard dust and light-liquid risks. Tyvek 500 handles splashes and stricter hygiene areas. Tyvek 600 is my top pick for the toughest chemical and biohazard scenarios.

How to Choose the Right Tyvek Disposable Coveralls for Your Task?

I recommend choosing the right Tyvek disposable coverall for safety and comfort at work. Here’s my guide to help you pick based on certifications, use cases, and fit.

Tyvek Coverall Certification Levels and Application Matching

Painting & General Cleanup:

They protect from fine dust, aerosols, and light liquid splashes.

I suggest them for spray painting, cleanrooms, food processing, pharmaceuticals, and daily maintenance.

Asbestos Removal & Chemical Handling:

Choose Type 4 Tyvek coveralls for protection against liquid aerosols and sprays.

For the best chemical and pressurized liquid barriers, Type 3 coverall suits offer maximum protection.

Cleanroom or Laboratory Environments:

I prefer Type 5/6 with antistatic features (EN 1149-5). They have low lint and resist liquids and particles.

Look for these standards: EN 13982-1 (particle tight), EN 13034 (spray tight), EN 1073-2 (radioactive), EN 14126 (biohazard).

Core Factors in Selecting Tyvek Disposable Coveralls

Level of Hazard:

Check for official certification. Type 3 (liquids under pressure), Type 4 (sprays), Type 5 (dust/particles), Type 6 (light splashes).

Higher types increase protection. But they may reduce breathability and flexibility.

Comfort & Fit:

Tyvek coveralls weigh under 180g.

Elasticity at wrists, ankles, and waist promotes free movement.

Longer zippers and comfort fit designs help you put them on and take them off fast.

Budget:

More protective suits (Type 3/4) cost more than standard Type 5/6.

Bulk pack quantities vary. For example, Tyvek 400 comes 100 per box. This affects budget planning.

Correct Sizing:

Always refer to the disposable coverall manufacturer‘s sizing guide:

| Size | Chest (cm) | Height (cm) |

|---|---|---|

| S | 84–92 | 164–170 |

| L | 100–108 | 176–182 |

| XXL | 116–124 | 188–194 |

Upsize to fit extra apparel or for tasks that need heavy movement.

Tyvek Disposable Coverall Selection Checklist

Confirm certifications. Type (3, 4, 5, 6), EN 1149-5, EN 13982-1, EN 13034, EN 1073-2, EN 14126.

Match the size chart to the wearer’s body measurements and expected activity.

Define your application. Is it for painting, cleanroom, asbestos, or chemical hazards? This helps you match the coverall model.

Review seam construction:

- Serged for dry, low-risk jobs.

- Over-taped for better liquid and chemical resistance.

Inspect features:

- Comfort-fit, storm flaps, hoods, booties, anti-static coatings, reinforced stress points.

Verify packaging and quantity needs. Individual or bulk boxes help with inventory management.

Example Tyvek Coverall Models and Sizing

Tyvek 400 (Type 5/6):

Blocks particles to 1 micron. Anti-static. Less than 180g per suit. Available in SM–3XL. I like it for painting, pharmaceutical, or cleanroom work.

Tyvek 600 Plus:

Has stitched and over-taped seams. Thumb loops. Elastic at cuffs and ankles. Best for chemical handling and higher risk zones.

Standard Sizing Reference:

L: 100–108cm chest, 176–182cm height

XXL: 116–124cm chest, 188–194cm height

Check for Certifications:

Always confirm EN 1149-5, EN 13982-1, EN 13034, EN 1073-2, and EN 14126 on each label.

Where to Buy Tyvek Disposable Coveralls: Best Retailers, Pricing, and How to Avoid Counterfeits

I recommend buying Tyvek disposable coveralls from trusted sources. Amazon, Home Depot, Grainger, PK Safety, EquipDirect, and official DuPont distributors are your best options. Sunrise Industries and Cleanroom World carry wide selections for industrial use.

Price Examples and Bulk Discounts

PK Safety: DuPont Tyvek 400 suit at ~$7.13 per piece, Medium to 5XL; poly-bagged per piece.

Equipment Direct: 25-count pack from $160.70–$217.37 ($6.43–$8.69 each).

JJ Keller, Sunrise Industries: Bulk case lots (25 units), sizes through 3XL.

Home Depot: Single suits for quick, local pickup.

Online purchases give you more size and style options. You’ll also get bulk pricing with 10–30% savings on volume orders. In-store shopping works better for urgent projects. You can check product quality before buying. You won’t wait for shipping either.

Tips to Ensure Authenticity and Find Deals

Use the DuPont distributor locator to confirm authorized sellers.

Check for branded packaging and documentation.

Compare prices. I suggest you avoid deals under $5/unit—they often sell counterfeits.

Look for promos on older models or case lots.

Verify reviews and return policies. For large industrial orders, request certifications.

How to Wear and Remove Tyvek Disposable Coveralls

Putting on and taking off Tyvek coveralls the right way keeps you safe. It protects the suit’s barrier from breaking down. I suggest you follow these steps. They help you stay safe and lower the risk of contamination.

How to Put On (Don) Tyvek Coveralls

- Sit on a clean chair. This keeps you stable.

- Put on protective footwear first. Use boot covers or safety shoes.

- Step into the legs one at a time. Pull the suit up to your waist while sitting.

- Stand up. Pull the suit over your body. Insert your arms into the sleeves.

- Wear a mask or respirator before pulling up the hood. Check for gaps.

- Zip up the Tyvek disposable coverall. Tuck your hair under the hood.

- Put on gloves. I recommend using two pairs for hazardous materials. Check that you can move freely.

How to Remove (Doff) and Dispose

- Unzip to your waist. Pull the hood off.

- Peel off the sleeves. Avoid skin contact with the suit’s outside.

- Roll the suit downward. Step out of each leg with care.

- Remove shoe covers. Discard all PPE as per protocol.

- Remove face protection last. Wash your hands well.

- Dispose of Tyvek disposable coveralls and PPE as contaminated waste. Never reuse them.

Essential FAQs and Tips

Tyvek disposable coveralls are not reusable. Dispose of them after one use.

Store in a dry, cool place. Keep the temperature at 15–30°C. Keep them out of sunlight.

Wear close-fitting clothes underneath. Bulky items can tear the suit.

Inspect suits before you use them. Check seam security every time.

I suggest you use gloves, boots, and a respirator with the coveralls. This gives you better protection.

Train all users. Bad procedures put people at risk.

Conclusion

Tyvek disposable coveralls provide lightweight, breathable, and highly protective solutions for dust, chemicals, and biohazards. From Tyvek 400 for light dust and splashes to Tyvek 600 for maximum chemical and infectious protection, these suits balance comfort, durability, and safety. Trusted in industries from pharmaceuticals to asbestos removal, they offer peace of mind on every job. For custom disposable coverall solutions or bulk orders, contact us for a personalized quote today.

Questions About Tyvek Disposable Coveralls

Are Tyvek disposable coveralls waterproof?

Tyvek disposable coveralls resist water, but they are not waterproof. They repel light splashes and sprays. This makes them ideal for jobs with occasional moisture or liquid exposure. They are not suitable for immersion. They also won’t protect against heavy or prolonged liquid exposure.

For better waterproofing, I recommend specialized models like Tyvek ProShield, Tyvek 500, Tyvek 600, or Tychem. These upgraded coveralls resist harsher liquids and chemicals. They offer strong barrier protection for tough environments.

What sizes do Tyvek disposable coveralls come in?

Tyvek disposable coveralls come in many sizes, from Small (SM) to 5XL. Some models, like the Tyvek 500 HV, come in sizes from SM to 3X. Getting the right fit matters for comfort and safety.

Manufacturers provide sizing charts. Many Tyvek suits have elastic wrists, ankles, hoods, and waists. These features ensure a secure and flexible fit for different body types and tasks.

Can Tyvek disposable coveralls protect against chemicals?

Standard Tyvek coveralls offer limited protection against mild chemical splashes and water-based solutions. For tasks with concentrated chemicals or aggressive liquid exposures, I suggest:

- Tyvek 500 for improved water-based chemical resistance

- Tyvek 600 for protection against stronger chemicals and increased barriers

- Tychem series for hazardous chemical environments and full splash protection

Always check chemical compatibility charts and permeation data before use. No coverall blocks all chemicals. Matching the suit to the actual hazard is crucial.

Are Tyvek coveralls breathable?

Yes, Tyvek materials are breathable. Their unique fiber structure lets vapors and sweat escape. This improves comfort for users who wear coveralls during long shifts. This balance between protection and breathability helps reduce heat stress in demanding settings.

What are typical uses for Tyvek disposable coveralls?

Based on my experience, common applications for Tyvek coveralls include:

Lead and asbestos abatement work

General maintenance, repairs, and facility operations

Spray painting, surface preparation, and cleanup

Mold remediation and insulation installation

Tasks in agriculture, food processing, healthcare, and pharmaceutical industries

How do Tyvek disposable coveralls differ from traditional cloth coveralls?

Tyvek disposable coveralls are single-use. They offer better filtration, liquid repellency, and biological hazard resistance compared to cloth coveralls. Cloth options can be reused after washing. But they allow more particle and liquid penetration. They can hold contaminants even after laundering.

Tyvek’s non-woven, continuous barrier is built into the material. Cloth relies on surface treatments. These treatments degrade over time.

Are Tyvek coveralls reusable?

No, Tyvek disposable coveralls are for single use. Reusing them can compromise their protective barrier. This is true after exposure to contamination, abrasives, or hazardous materials. Always dispose of used suits according to site safety procedures.

Do Tyvek coveralls protect against viruses and bacteria?

Tyvek coveralls block particles down to 1 micron. This offers a real barrier to many viruses, bacteria, and biohazards. For high-risk or regulated infection control roles, I recommend confirming that the chosen model meets specific biosafety requirements or standards.

How much do Tyvek disposable coveralls weigh?

Tyvek coveralls are lightweight, between 40 and 60 grams per square meter (gsm). This keeps the wearer’s fatigue low during extended operations or hot conditions.