Many buyers assume all disposable coveralls come from the same place, but prices and quality often vary a lot between suppliers. That’s why knowing where Kleenguard disposable coveralls are manufactured can help you understand their reliability and cost. In this post, I’ll walk you through the production origin, the facilities behind the brand, and how their global supply chain affects quality and delivery time.

What is the KleenGuard Brand?

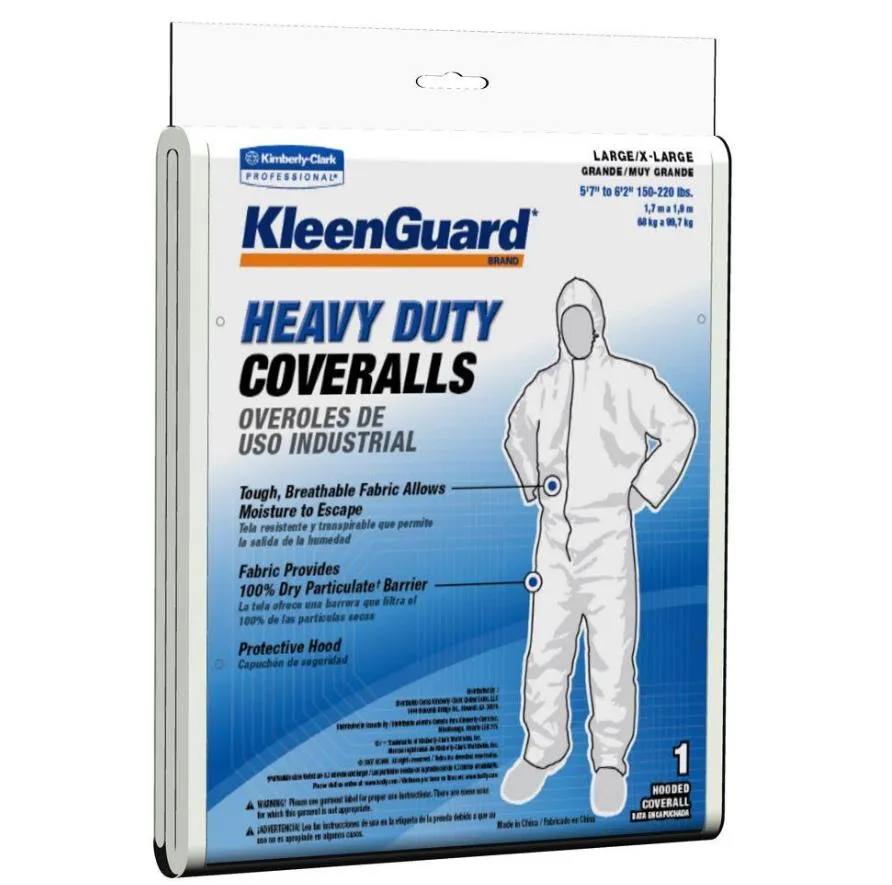

KleenGuard is a PPE brand of protective apparel, safety gloves , eyewear and related PPE that is (or was) part of Kimberly‑Clark Professional’s portfolio, now under Ansell via acquisition. When you buy a KleenGuard “coverall”, you are buying more than just fabric and stitches — you’re buying a product made under certain standards, by certain factories, in certain countries.

Where Are Kleenguard Disposable Coveralls Manufactured?

Kleenguard disposable coveralls are mainly manufactured in two countries: Mexico and China. These locations are key to the production of popular Kleenguard models such as the A10 and KGA35 series.

Manufacturing Locations: Mexico and China

Mexico: Many Kleenguard coveralls , including sizes from S to 5XL of the A10 and KGA35 lines, are produced here. Product details often list “Country of Origin: Mexico.”

China: Some KGA35 coveralls also come from factories in China, confirmed by labeling “Country of Origin: China.”

Why Mexico and China?

Several factors influence Kleenguard’s choice of manufacturing sites:

Cost Efficiency: Both countries offer lower labor and operational costs, reducing production expenses.

Quality Assurance: PPE factories in Mexico and China meet ANSI/ISEA protection standards. This guarantees the disposable coveralls meet strict quality and safety requirements.

Regulatory Compliance: These sites comply with international and local regulations for protective gear, supporting reliable and legal manufacturing processes.

Shipping and Supply Efficiency: Most suppliers can ship over 95% of Kleenguard orders within 24 hours, thanks to centralized warehouses supporting these manufacturing hubs. This quick turnaround benefits industries requiring fast restocking of protective gear.

Examples and Product Data

- The KGA35 Disposable Coveralls are available in a wide range of sizes (S–5XL) and made in both Mexico and China.

- Specific product codes such as Kleenguard™ A10 (product 10616) are made in Mexico, while KGA35 (product 38937) is manufactured in China.

In conclusion, Kleenguard Disposable Coverall manufacturing focuses on Mexico and China due to cost advantages, quality standards, and regulatory rules. These locations allow flexible production of safe and reliable disposable PPE for various work environments.

Materials Used in KleenGuard Disposable Coveralls

KleenGuard disposable protective coveralls are made from specialized materials designed for protection, comfort, and durability.

Main Fabric Types

Microporous Film Laminate: This is the primary material used in models like the KleenGuard KGA300 and A40. It combines layers of polypropylene and polyethylene to create a breathable barrier. It protects against hazardous particles and light liquids while allowing air flow for comfort.

MicroForce Barrier Fabric: Used in the A20 model, this fabric focuses on dust and grime protection. It is breathable and antistatic, suitable for environments where dust control is important.

Key Material Features of Kleenguard Coveralls

Latex- and Silicone-Free: This helps reduce allergic reactions and is better for sensitive users.

High Durability: For example, the A40 model’s fabric is 37% stronger and 2.5 times more tear-resistant than competitor fabrics.

Low Linting: Produces up to 90% less lint, essential for cleanroom and pharmaceutical uses.

Ergonomic Design: Features like elastic wrists and ankles, water-resistant zippers, and a Reflex® design that provides 12% more chest room and longer body length.

Examples of KleenGuard Disposable Coverall Materials and Features

| Model | Material Type | Durability & Protection |

|---|---|---|

| KGA300 | Microporous film laminate | Protects against light liquids & dust |

| A40 | Microporous film laminate | 37% stronger, 2.5x tear-resistant |

| A20 | MicroForce barrier fabric | Dust and grime barrier |

In conclusion, KleenGuard disposable coveralls rely on advanced microporous and polypropylene-based fabrics. These materials ensure strong protection against particles and liquids while maintaining comfort and compliance with industry safety standards.

Kleenguard Disposable Coverall Manufacturing Quality and Standards

Kleenguard disposable coveralls are manufactured with strict quality control to ensure safety, durability, and comfort. Here are the key quality measures and certifications involved in their production:

Quality Control Measures of Kleenguard Coveralls

Individual Packaging: Each safety coverall is packed in a clear polybag to maintain cleanliness and product integrity.

Seam Construction: Over-locked stitched seams provide strength and comfort, especially in areas prone to exposure.

Antistatic Treatment: Fabrics meet NFPA 99 and EN 1149-5:2018 standards to reduce static risks, important in sensitive environments.

Fit Design: Reflex® Design offers 12% more chest room and 6% longer body length than ANSI minimums for better fit and mobility.

Certifications and Safety Standards of Kleenguard Coveralls

ISO 9001 Certification: Ensures manufacturing consistency and quality management.

ASTM Standards Passed:

- F1670 for synthetic blood penetration protection.

- F1671 for bloodborne pathogen resistance.

- F903 for chemical barrier performance (e.g., isocyanate paint, potassium chromate).

- F1001 for chemical penetration and permeation resistance in certain models.

NFPA 99: Validates antistatic material properties.

European EN Standards:

- EN ISO 13982-1:2004+A1:2010 (Type 5) for particle protection.

- EN 13034:2005+A1:2009 (Type 6) for limited liquid splash protection.

- EN 1149-5:2018 for antistatic performance.

- EN 1073-2:2002 for radioactive dust protection.

- ISO 6530:2005 class 3 repellency for various hazardous chemicals.

Manufacturing Practices and Performance of Kleenguard Coveralls

Material: Microporous film laminates provide breathability plus strong barriers against dust, splash, and chemicals.

Testing: Regular batch testing confirms compliance and quality:

- Produces up to 90% less lint than competitors, critical for cleanrooms.

- Fabric strength is 37% higher and tear resistance is 2.5 times better compared to leading competitors (for A40).

- Strong taped seams enhance protection, seen in A80 models.

PPE Category III: Complies with EU PPE Regulation 2016/425 for high-risk applications.

User Safety Features: Latex-free, silicone-free, seamless fronts, and respirator-compatible hood design.

Clear Guidance: Sizing charts and usage instructions ensure optimal protection.

Packaging and Industry Use of Kleenguard Coveralls

Standard Packaging:

- A40 and similar models: 25 coveralls per case.

- A80 and higher-protection models: 12 coveralls per case.

Typical Applications: Widely used in pharmaceutical production, cleanrooms, electronics, labs, paint spraying, industrial maintenance, hazardous material handling, agriculture, and remediation work.

This manufacturing quality and certification portfolio ensures Kleenguard disposable coverall suits offer trusted protection, durability, and comfort for demanding professional environments.

Environmental Considerations of Disposable Coverall Manufacturing

KleenGuard disposable coveralls are made using petroleum-based plastics like high-density polyethylene (HDPE) and SMS polypropylene. These materials come from non-renewable resources and require energy-heavy processes such as extrusion, spinning, and weaving. This manufacturing process results in significant greenhouse gas emissions and uses a large amount of water and energy.

Environmental Impact of Manufacturing

The production chain includes raw material extraction, manufacturing, packaging, and transport, each contributing to energy use and greenhouse gas emissions.

Chemical additives like plasticisers, flame retardants, and UV stabilisers are used, which can be harmful when leached into the environment.

Millions of disposable PPE coveralls end up in landfills or are incinerated worldwide, causing microplastic pollution and toxic emissions.

Sustainability Efforts by KleenGuard

KleenGuard’s parent companies promote waste tracking and aim to reduce environmental footprints. However, specific data on recycled content or recycling rates for KleenGuard products is limited. Some strategies to lessen impact include:

Using renewable energy in manufacturing

Reducing single-use plastics in packaging

Exploring recycled fibers and eco-friendlier raw materials

What This Means for Buyers?

KleenGuard coveralls are non-biodegradable and persist in the environment for hundreds of years as microplastics. Eco-conscious buyers should consider reusable alternatives or products made from recycled materials. Checking if manufacturers have certified sustainability programs or measurable waste reduction goals can guide more responsible purchases.

How to Verify Authentic KleenGuard Disposable Coveralls?

Check Certifications: Look for compliance with standards like ANSI/ISEA 101 and CE certifications on the packaging.

Inspect Product Labels: Genuine products have clear KleenGuard logos and model codes like 68968 (KGA20) or 46003 (A30).

Confirm Purchase Source: Always buy from authorized distributors or official Kimberly-Clark or Ansell websites.

Avoiding Counterfeit Coveralls

- Watch out for poor packaging and misspelled labels.

- Be cautious if the price is significantly lower than average.

- Use disposable coverall manufacturer verification tools or contact customer support.

- Genuine products often include a manufacturer’s warranty or quality guarantee.

By verifying the manufacturing origin and following these tips, you can ensure that the KleenGuard Disposable Coveralls you buy are authentic and reliable.

FAQ for Kleenguard Disposable Coverall

Q1: Are KleenGuard disposable coveralls available in all countries?

Not all models are sold worldwide. Some, like A10 or A20, are mainly available in North America and Europe, while others such as KGA35 are often stocked in Asia. Availability depends on import regulations and warehouse locations. It’s best to check with authorized distributors to confirm regional supply before placing large or long-term orders.

Q2: How can I confirm where my KleenGuard coveralls were made?

You can check the product box or bag. It usually says “Made in Mexico” or “Made in China.” If you order from a distributor, ask them for the batch or lot number. That code helps trace which factory made your items. Reputable suppliers always provide clear documentation, especially for industrial or hospital use.

Q3: Does the manufacturing country affect product quality?

Not directly. Both Mexican and Chinese factories must follow KleenGuard’s standards for materials, seams, and barrier protection. Quality depends more on factory control and inspection than geography. However, differences in stitching, packaging, or sizing sometimes occur between batches. If you notice inconsistency, contact your supplier or check the official KleenGuard specification sheet.

Q4: Are KleenGuard disposable coveralls single-use or reusable?

KleenGuard coveralls are designed for single use. They protect against dust, light liquid splashes, and non-hazardous chemicals. Reusing them may reduce protection and comfort because the seams and material weaken after one wear. For long-term or heavy-duty tasks, it’s better to choose reusable coveralls made from washable FR or coated polyester fabrics.

Q5: What is the shelf life of KleenGuard disposable coveralls?

The average shelf life is about five years if stored in a clean, dry place away from sunlight and moisture. Over time, the material may lose its protective barrier. Always check the packaging for the production date and use items within the recommended period for full protection and performance.

Q6: What should I check before accepting a KleenGuard coverall shipment?

Inspect the label for model and country of origin, verify batch or lot number, and compare the specs with your order sheet. Open one piece to test stitching, seam sealing, and material feel. Make sure packaging is clean and undamaged. If any details seem off, ask your supplier to confirm whether the items come from approved factories.