Ever wondered what makes surgical masks, gowns, and wound dressings safe and effective? The answer often lies in medical non-woven fabric. Unlike traditional textiles, these engineered materials are designed for single use, offering superior protection against infections, fluids, and contaminants. Discover why this innovation is critical for patient safety, hygiene, and modern medical practices. Learn how this unsung hero is vital in healthcare!

What Are the Main Components of Medical Non-woven Fabric?

Based on my experience, medical non-woven fabrics are made using different fibers. Each fiber is chosen for its unique properties that work well in healthcare settings.

Polypropylene (PP) in Medical Non-woven Fabrics

Polypropylene makes up more than 80% of the medical non-woven market. I believe it is popular for a few reasons:

– It’s affordable.

– It’s lightweight.

– It provides a strong barrier.

– It is easy to process with modern techniques.

Two main methods are used to make polypropylene fibers: spunbond and meltblown.

– Spunbond PP: This type is strong. It’s used in products like surgical gowns and caps.

– Meltblown PP: This is a fine fiber. I recommend it for the core filtration layer in surgical masks and N95 respirators.

For instance, surgical masks use 2–3 layers that combine both spunbond and meltblown PP. The total weight is around 20–30 grams per square meter (gsm). Medical gowns are made from 35–50 gsm spunbond or SMS (spunbond-meltblown-spunbond) PP fabric.

Polyester and Viscose (Rayon) Blends

- Polyester

adds strength and chemical resistance to fabric. It does not absorb liquid. - Viscose

(rayon) adds softness and helps the fabric absorb liquids. It is also biodegradable.

I suggest blending polyester and viscose with polypropylene. This practice helps create a balance of:

– Strength

– Softness

– Absorbency

A medical drape might use spunlace blends of polyester and viscose. These fabrics weigh 40–80 gsm. I find they are valued for surgical wipes and drapes because they offer better strength and absorbency.

SMS Non-woven Fabric Structure

An SMS non-woven fabric combines two key features.

– The barrier function of meltblown polypropylene.

– The strength of spunbond polypropylene.

In my opinion, this layered approach creates a fabric that is strong and offers high protection. This makes it perfect for medical drapes and sterile packaging.

Raw Material Usage Examples

- Surgical masks: 2–3 layers (spunbond and meltblown PP), 20–30 gsm

- Medical gowns: 35–50 gsm spunbond or SMS PP

- Surgical drapes: Spunlace polyester/viscose blends, 40–80 gsm

I have to stress that medical non-woven fabrics must meet strict quality standards. These include BFE (Bacterial Filtration Efficiency), breathability, linting control, and resistance to fluids and blood. Based on my experience, these materials are key to ensuring safety and performance in healthcare today.

How Medical Non-woven Fabrics Are Made: Spunbond, Meltblown, and SMS

Medical non-woven fabrics are made with special production methods. These methods focus on both safety and speed. In my experience, the two main technologies are spunbond and meltblown. Each one offers unique advantages for medical products.

The Spunbond Process for Medical Fabric

In the spunbond process, makers melt plastics like polypropylene. They push the melted plastic through tiny holes to create long, unbroken threads. These threads then cool down. They are laid out on a moving belt, which forms a soft sheet of material. To hold it all together, heat, chemicals, or pressure are used to bond the web.

- Features:

The final fabric is strong, breathable, and lasts a long time. It is used for products like surgical gowns, masks, and drapes. - Industry Application:

I believe spunbond creates a fabric that is both soft and strong. This makes it a great choice for items that touch the skin in hospitals.

Meltblown Technology and Its Filtering Power

The meltblown method also starts by melting plastics. The plastic is then forced through a line of tiny nozzles. A blast of high-speed air turns it into super-fine fibers, often smaller than 2 micrometers. These tiny fibers create a dense web that is excellent for filtering.

Key Benefits:

I think meltblown fabric is vital for surgical masks and respirators. It does a great job of filtering out bacteria and viruses.

Industry Innovation:

For example, I saw that Berry Global Inc. released a new meltblown technology in 2023. This improved how well medical masks can filter the air.

SMS Composite Structure: A Blend of Strength and Filtration

I suggest looking at SMS non-woven fabrics, which stand for spunbond-meltblown-spunbond. Makers create it by placing a meltblown layer between two spunbond layers. This is a smart way to combine the strength of spunbond with the filtering power of meltblown.

Result:

This combined fabric is used for many things, like medical gowns, drapes, and sterile packaging.

Bonding Techniques:

Based on my knowledge, common ways to bond the layers include heat, glues, or physical methods like needlepunching. The method chosen depends on what the final fabric needs to do.

Strict Industry Standards and New Advances

From what I’ve seen, producers must follow strict rules like ISO 22610, EN 13795, and AAMI PB70. I know that key product needs include:

- A strong barrier against liquids and germs

- Good breathability and absorption

- The ability to be cleaned with methods like autoclave (steam) and gamma irradiation

New technologies are making a big difference. I’ve noticed faster production lines and the use of sustainable raw materials. This helps create better medical non-woven fabric products in less time. I also see a stronger push for green options to meet people’s environmental hopes.

Key Benefits of Medical Non-woven Fabrics

From my experience, medical non-woven fabrics are special. They are lightweight, breathable, and provide great protection. They are also sterile and comfortable for users. I believe these features are what make them so vital in healthcare.

Breathability and Lightweight Structure

I feel spunlace non-woven fabrics are impressive. They are very breathable and light. Their weight is typically between 10–50 g/m². This lightweight material makes them perfect for surgical masks, gowns, and wound dressings.

Good airflow and comfort are necessary for these items. Spunlace fabrics let air and moisture pass through easily. This helps wounds heal naturally. It also reduces discomfort from heat and sweat. I think this is a huge benefit for patients and doctors who must wear them for a long time.

Case in point:

Nonwoven medical dressings let air and moisture through. This promotes healing and makes them more comfortable to wear. Market reviews show a strong preference for these fabrics in medical masks, gowns, and dressings. Their lightness and breathability are the main reasons why.

High Barrier Protection Against Fluids and Pathogens

In my view, preventing infection is a top priority in healthcare. Medical non-woven fabrics solve this problem. They use layered meltblown and spunbond structures. These structures block liquids and particles in the air. I’ve seen how meltblown layers in masks and gowns offer great filtration:

– A single layer of nonwoven material filters about 42 ± 2% of tiny particles.

– With a double-layer, you get 54 ± 1% particle filtration. This can go up to 93% for bacterial filtration efficiency (BFE).

This barrier physically stops germs. It lowers the risk of infection in hospitals and clinics. I’m also excited about new developments. For instance, some new bioresorbable dressings can dissolve into the body. They deliver medicine directly to a wound while still protecting it.

Practical examples:

Medical masks and isolation gowns use these powerful non-woven layers. I suggest looking at wound dressings. They often mix meltblown PP for filtering with spunlace cotton or viscose. This adds absorption and comfort.

Sterility, Safety, and Comfort for Users

Manufacturers produce all medical non-woven fabrics in clean, sterile rooms. Based on my experience, their structure is a key safety feature. They don’t stick to skin and are hypoallergenic, which prevents irritation. This makes them safe to wear against the skin for long periods.

Factories use methods like water jets (hydroentanglement) and sound waves (ultrasonic bonding). This means no toxic glues are needed. I believe this is better for both the fabric and the patient’s safety.

The fact that they are disposable is another safety plus. You use a mask or gown once, then throw it away. This stops germs from spreading between people. I also find that comfort is a huge selling point. They have soft finishes, help manage temperature, and fit well. It’s no surprise that healthcare workers prefer them.

Brand examples:

If you look at products from companies like Welspun and KNH, you’ll see this in action. Their patient wipes, drapes, and protective gear are known for being breathable, filtering well, and keeping users safe all day.

Key Figures and Market Trends

Medical masks using these fabrics perform better than cotton. They meet or beat standards for filtration and breathability (pressure differential ≤49 Pa, filtration >30%).

I’ve noticed the demand for medical non-woven fabrics is growing fast in the Asia-Pacific region. The market is expected to grow at a rate of 7.1% each year through 2028.

Applications of Medical Non-woven Fabric

From my experience, medical non-woven fabrics are key in hospitals and clinics. They provide a strong barrier against germs. This helps prevent infections and also saves money.

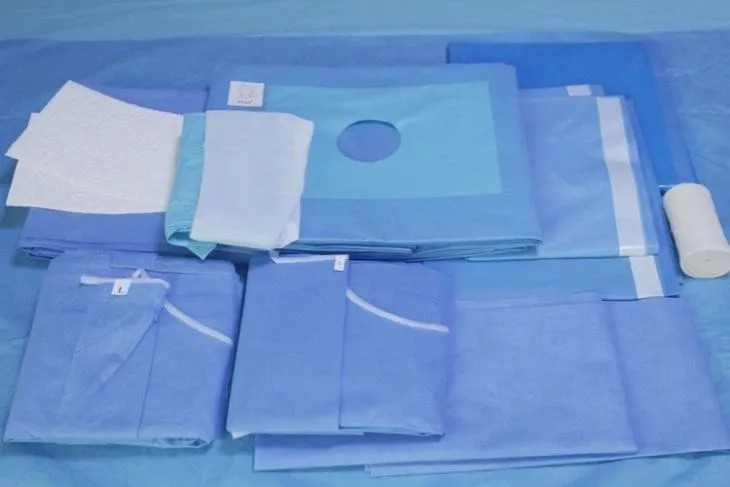

Surgical Gowns, Drapes, and Caps: Infection Control on the Front Lines

I have seen that disposable surgical products made from medical non-woven fabrics are the most common. Hospitals demand them for the best infection control.

Take surgical gowns, drapes, and disposable caps. I recommend using the ones made from non-woven polypropylene. They block fluids and bacteria well. They are also breathable, which keeps staff comfortable during long surgeries.

In 2023, hospitals used over 445,000 metric tons of these materials. That created a market worth $1.44 billion for just this segment.

Newer cotton-based nonwovens are a great development. I find them 30–50% more breathable in surgical gowns. This improves comfort and is better for the environment. These materials can cut carbon emissions by at least 50% compared to fabrics made only from synthetics.

Using single-use surgical nonwovens is now the standard practice. I believe this is because they meet strict safety rules and offer a strong defense against spreading germs.

Medical Face Masks, Respirators, and Disposable Coveralls

I suggest using Polypropylene for making medical masks and respirators. It is a top choice. People like it because it is lightweight, safe for sensitive skin, and filters particles very well.

A meltblown layer is a must-have in any mask design. I think it is the most important part. It traps harmful germs and viruses, which protects both patients and medical staff.

You will always find disposable coveralls in infectious disease wards. They were also essential during pandemics. They give healthcare workers full protection from liquids and germs.

The demand for these items is growing. The global medical-grade polypropylene non-woven fabric market should reach $2.5 billion by 2025. It is expected to grow at a rate of 5% through 2033.

Hospital infections are a big, expensive problem. U.S. facilities lose $35.7–45 billion each year from infections that could be prevented. Based on my experience, changing to nonwoven barrier materials can make a huge difference. Doing so could stop up to 70% of these cases, which directly improves safety and saves money.

Medical Wrapping and Sterilization Packaging

In my opinion, sterilization wraps and pouches from non-woven fabric are the best choice. They are great for storing sterile instruments. They are made for one-time use, which greatly reduces the chance of contamination before surgeries.

Many people choose polypropylene-based wraps. I recommend them because they have a strong barrier against microbes. They keep instruments sterile, but let sterilization gases get through.

In 2024, hospitals and clinics used 51.31% of all medical nonwovens in the world. This shows just how common they are in medical settings.

Today, advanced sterile packaging is made in very clean environments called Class 8 cleanrooms. I believe this shows how seriously infection control is taken in the healthcare supply chain.

Key Factors for Choosing Medical Non-woven Fabric

Choosing the right medical non-woven fabric is very important. I believe it affects safety, performance, and following the rules in healthcare. Here are the most important things I look for:

Thickness, GSM, and Fiber Composition of Medical Non-woven Fabric

Thickness

affects how well the fabric blocks fluids and germs. Thicker fabrics give you more protection. But they might be less comfortable and breathable. I choose thinner fabrics for maximum comfort in less critical situations.

GSM (Grams per Square Meter):

Medical non-woven fabrics range from 15–50 GSM.

35–50 GSM: I use these for products that need to be tough and resist fluids, like surgical gowns and drapes.

20–30 GSM: This is ideal for disposable face masks and caps where comfort and low cost are key.

Fiber Composition:

Polypropylene SMS (Spunbond-Meltblown-Spunbond): This is my top choice for critical barrier needs. It gives high bacterial and viral filtration with very little lint.

Blends (e.g., polyester, wood pulp, or cotton): I use these in cases where I need extra absorbency or softness.

Biocompatibility: The materials must be safe for direct skin contact. They should not cause any irritation.

International Standards of Medical Non-woven Fabric

| Standard | Description |

|---|---|

| ISO 13485 | Key certification for managing the quality of medical devices. |

| EN 13795 | Sets the basic standards for sterility, strength, and barrier quality in surgical drapes and gowns. |

| ASTM D5034 | Tensile strength |

| ASTM D1777 | Thickness |

| ASTM D5587 | Tear strength |

| ASTM D1175 | Abrasion resistance |

| ISO 811 | Water resistance (hydrostatic head) |

| EN 1149 |

Antistatic properties |

| AAMI PB70 | This standard sets barrier levels from 1–4. Higher levels are strongly recommended for high-exposure areas like operating rooms. |

Medical Non-woven Fabric Supplier Quality, Certification, and Traceability

Medical Non-woven Fabric Supplier Selection:

I suggest you look for non-woven suppliers with proof of ISO 13485 certification and FDA approval. They should also provide test documents for each batch.

I always ask for reports that show they meet local and international standards.

In my experience, you should choose non-woven suppliers with a good track record. They need to provide materials that are safe for the skin, can be sterilized, and are always consistent.

Certification & Audits For Medical Non-woven Fabric Supplier:

You should confirm they have regular checks from outside groups to verify they are following the rules.

I always make sure that lot traceability, batch test records, and reliability data are easy to get.

Practical Examples and Data

Surgical Gowns: I recommend SMS fabric (35–45 GSM). The three-layer design gives strong fluid protection and meets standards like EN 13795 and AAMI Level 3/4.

Face Masks: Spunbond-meltblown-spunbond PP, 20–30 GSM, must be tested for BFE and PFE.

Sterilization Wraps: SMS or spunlace, 40–50 GSM, tested per ASTM F88/F88M and F1670/F1671.

Additional Selection Factors For Medical Non-woven Fabric

Sterilizability: The fabric must handle sterilization methods like autoclave, ethylene oxide, or gamma rays. It should do this without losing its effectiveness.

Barrier & Fluid Resistance: I think this is the top priority for surgery and critical areas. We test the fabrics with specific water pressure and penetration standards.

Comfort & Breathability: These are very important for long-term wear. I suggest choosing a lower GSM or blended fabrics for more softness.

Innovative Options: I like to consider new choices. These include antimicrobial finishes, biodegradable materials, and green blends.

Intended Use: From my experience, you must always match the fabric to the medical situation. I prioritize higher protection for the most critical zones.

Typical Medical Non-woven Applications and Suitable Fabric Types

- Isolation gowns: SMS or SMMS, 20–35 GSM

- Sterilization wraps: SMS, spunlace, 40–50 GSM

- Surgical drapes/gowns: SMS, 35–45 GSM, high barrier

- Face masks: Spunbond/meltblown, 20–30 GSM

- Wound dressings: For these, I find that absorbent, hydroentangled blends work best.

Based on my experience, balancing all these factors is the key. When you balance thickness, GSM, fiber blend, and supplier quality, your medical non-wovens will provide the best safety, comfort, and performance.

New Ideas in Medical Non-woven Fabrics: Smart, Germ-Fighting, and Green Solutions

From my experience, I’ve seen major growth in smart medical non-woven fabrics and germ-fighting treatments. Smart medical non-woven fabrics have built-in sensors or electronics. I think they are useful for:

* Watching vital signs

* Checking on wound healing

* Helping deliver medicine

For example, some non-woven textiles can now conduct electricity. This allows for the creation of smart bandages and wearable health monitors.

Germ-Fighting and Infection Control Features

I notice that treatments with silver, copper, or zinc are very popular. These metals help stop germs. This makes disposable surgical gowns, masks, and drapes much better at protecting people from bacteria and infections they might get in a hospital. In 2024, I saw that fabrics that are sterile, antibacterial, and can soak up fluids accounted for over 60% of the market. You will find them used heavily in surgical units to prevent infections.

Green Materials For Medical Non-woven Fabric

I see the industry shifting to materials that are better for the planet, like PLA and bamboo fiber blends. These options can break down naturally. Manufacturers now face more demand for green production and certifications like OEKO-TEX, ISO, and ASTM. This is very common in Europe and Asia. I find that hospitals and governments are driving this change. They want to use more sustainable non-wovens to reduce their carbon footprint.