China Latex Glove Manufacturer

We are a leading latex gloves manufacturer in China, supplying high-quality disposable and reusable gloves for industrial, household, and cleaning applications. Our gloves are made from natural latex with strong grip, good elasticity, and durable protection against dirt, oil, and chemicals. With stable production and factory-direct prices, we help global buyers source reliable latex gloves for daily and professional use.

Certifications of Latex Glove Supplier

EN388:2016

This standard tests latex gloves for mechanical protection, including abrasion, cut, tear, and puncture resistance, ensuring safe handling in industrial and laboratory environments.

EN374-5

EN374-5 certification confirms that latex gloves protect against bacteria, fungi, and viruses, providing essential defense for healthcare and laboratory professionals handling infectious materials.

EN374-2

This test measures the latex gloves’ resistance to liquid and microbe penetration, ensuring a reliable barrier against chemicals and biological hazards during medical or cleaning tasks.

EN420

EN420 defines general safety requirements for latex gloves, including size, comfort, and labeling, guaranteeing they fit well and perform effectively in professional environments.

CE

CE marking shows the latex gloves comply with European health, safety, and environmental protection standards, allowing safe sale and use throughout the European market.

.png)

EN1186

How to Custom Latex Gloves?

Choose the Right Material of Safety Gloves

We supply gloves in latex, nitrile, vinyl, PVC, PE, and neoprene.

-

Latex: soft, elastic, and ideal for medical and cleaning work.

-

Nitrile: strong chemical and oil resistance.

-

Vinyl / PE: cost-effective for light-duty use.

Each material meets export standards and can be customized for powder-free or textured designs. We’ll help you pick the best material for your work and budget.

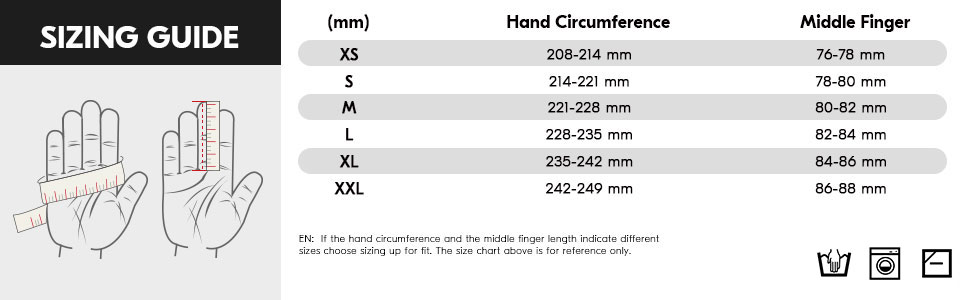

Custom Size and Thickness of Latex Gloves

Available glove sizes: S, M, L, XL, XXL.

-

Palm width: 80–115mm

-

Length: 240mm or 300mm (long cuff optional)

-

Thickness: 3.5–7 mil depending on protection level

All gloves are tested for stretch, tear resistance, and comfort. You can choose light, medium, or heavy-duty models based on your usage.

Custom Color for Latex Gloves

Choose any glove color you like — white, blue, yellow, green, black, or Pantone-matched custom shades.

-

Medical use → white or blue

-

Industrial cleaning → yellow or green

-

Food or lab work → transparent or light color

We use eco-friendly pigments, ensuring color consistency and no irritation during use.

Add Logo to Your Latex Gloves

Make your brand visible with printed or embossed logos on gloves or packaging.

-

Printing method: screen print / laser mark

-

File format: AI, PDF, PNG

Your logo can be placed on the cuff, box, or bag, helping distributors and brands stand out. We offer quick sample confirmation before mass production.

Top Latex Glove Factory

Watch how our latex gloves are produced in a clean and well-organized factory. Every step—from raw latex processing to final inspection—follows strict quality control to ensure safety and consistency. Our video also shows real moments from international exhibitions, where we meet clients, present new glove designs, and discuss future cooperation. Together, these scenes reflect our strong production capability and global presence as a trusted latex glove manufacturer and supplier.

Why Choose Us As Your Latex Gloves Manufacturer?

Manufacturer with 20 Years of Experience

With over 20 years in glove manufacturing, we know what quality means. Our factory follows strict production standards to make every pair reliable and safe. From raw latex processing to final packing, every step is checked carefully. We’ve worked with hospitals, factories, and distributors worldwide, offering a steady supply and trusted quality.

Low MOQ for Flexible Orders

Morntrip supports a low minimum order quantity, starting from just 10,000 pcs for new customers. It’s perfect for testing new markets or adding new glove types to your catalog. Whether you need one container or a small trial batch, our production team adjusts quickly to meet your plan without extra setup costs.

Latex Gloves At Low Price

Strict Quality Control System

Free Samples for Quality Checking

Fast Production and On-Time Delivery

Medical Gloves Manufacturer

Household Gloves Manufacturer

Industrial Gloves Manufacturer

Disposable Gloves Manufacturer

FAQ of Safety Gloves Manufacturer

What is the average monthly production capacity of your gloves?

Our glove factory produces millions of gloves every month, including latex gloves, nitrile gloves, vinyl gloves, and PVC gloves. With multiple automated production lines operating simultaneously, we can handle both small trial orders and large bulk orders for distributors. Monthly output ensures a stable supply for hospitals, factories, and industrial clients. Production schedules are carefully managed to maintain quality and consistency across batches. This capacity allows B2B buyers to plan inventory efficiently, meet seasonal demand, and reduce the risk of stock shortages while maintaining competitive pricing in their markets.

Can buyers mix different glove materials in one order?

Yes, orders can include a mix of glove types such as latex, nitrile, vinyl, and PVC gloves in a single shipment. This flexibility allows distributors to offer a diverse product range to meet different customer needs, from medical examination gloves to industrial and cleaning gloves. Each glove type is packaged separately but shipped together to simplify logistics. Buyers can mix sizes, colors, and textures like powder-free or textured gloves in one container. This option saves shipping costs and ensures consistent delivery schedules, making it ideal for B2B clients managing multiple markets or diverse end users.

How to manufacture latex gloves?

Latex gloves are made through a dipping process using high-quality natural latex. Clean hand-shaped molds are dipped into liquid latex, followed by curing, leaching, and drying to ensure strength, flexibility, and comfort. After removal from molds, gloves are washed, powdered or powder-free treated, inspected for holes and defects, and finally packaged. Modern automated lines allow consistent thickness, texture, and size control. Additional processes like texturing or coloring can be applied based on client needs. This method ensures each pair of latex gloves meets industrial or medical standards, providing reliable protection for B2B customers worldwide.

How long is the shelf life of gloves?

The shelf life of gloves depends on the material, storage, and packaging. Generally, latex, nitrile, and vinyl gloves last two to three years if kept in a cool, dry place away from sunlight and heat. Proper storage preserves elasticity, grip, and barrier protection, ensuring gloves perform reliably when used. For wholesale gloves buyers handling bulk shipments, it is recommended to follow a first-in, first-out inventory system. This prevents older stock from losing effectiveness and maintains safety standards for medical, industrial, and cleaning applications. Regular stock rotation also helps minimize waste and ensure consistent product quality.

Can you produce gloves with special thickness or extra-long cuffs?

Yes, we can manufacture gloves with custom thicknesses ranging from light-duty three to four mils to heavy-duty six to seven mils for industrial or laboratory use. Extra-long cuffs are available for applications requiring extended forearm protection, such as chemical handling or food processing. B2B buyers can specify the exact size, length, and thickness to suit end-user safety requirements. Each batch is tested to ensure consistent strength and flexibility. This flexibility allows distributors to supply latex, nitrile, or PVC gloves for specialized industrial, laboratory, or medical tasks, meeting diverse customer demands and regulatory standards.

What packaging options are offered for bulk glove orders?

Bulk orders can be packed in polybags, color boxes, or standard cartons, with each box labeled with size, material, and batch number. For large orders, pallets can be used to simplify logistics and reduce handling damage. Clients can also request custom packaging layouts to combine different glove types in one shipment. Packaging is designed to protect latex, nitrile, vinyl, or PVC gloves during transport, maintain hygiene, and make warehouse management easier for distributors. Efficient packaging ensures smooth delivery, reduces breakage, and helps B2B buyers streamline inventory storage and order fulfillment.

What industries are your gloves suitable for?

Our gloves serve a wide range of industries. Latex and nitrile gloves are commonly used in medical, laboratory, and food processing sectors, while PVC and rubber gloves suit cleaning, chemical handling, and industrial work. Safety gloves also protect workers in manufacturing plants, automotive workshops, and janitorial services. Different textures, thicknesses, and powder-free options ensure proper grip, barrier protection, and comfort for each application. B2B buyers can rely on our diverse glove portfolio to serve multiple sectors with a single supplier, making inventory and logistics more efficient and reducing the need to source from multiple manufacturers.

Can bulk glove orders be split into multiple shipments?

Yes, large orders can be divided into multiple shipments based on buyer requirements, helping manage warehouse space and cash flow. Each shipment can include different glove types or sizes, including latex, nitrile, vinyl, or PVC gloves, while maintaining batch tracking and consistency. Partial shipments also allow B2B clients to meet urgent market demand before the full order is ready. Our logistics team coordinates delivery schedules to ensure smooth and timely arrival of all shipments. This flexible approach supports distributors in handling seasonal demand, sudden market spikes, or multi-location storage needs efficiently.

What logistics partners are used for global glove shipments?

Morntrip collaborate with reliable international logistics partners for sea, air, and express shipping. Major carriers ensure safe transport for latex, nitrile, vinyl, and PVC gloves worldwide. Shipments are fully tracked, and customs documentation is prepared to simplify import procedures for B2B buyers. Packaging is designed to protect gloves from moisture, impact, and contamination during transit. Long-term partnerships with freight forwarders allow priority scheduling, faster delivery, and competitive shipping costs. Buyers can choose shipping methods based on urgency, cost, and destination, ensuring gloves reach customers safely and on time across global markets.

How do you handle damaged gloves during transit?

Our logistics team carefully inspects every shipment before dispatch, and gloves are packed in sturdy boxes or cartons to prevent damage. In the rare event of damaged gloves, clients can report the issue within a few days of receipt. We provide replacements or partial refunds based on the damage report. Gloves are also labeled clearly to track batches during transit, ensuring accountability. For high-value or large shipments, additional protective packaging is applied. This system minimizes losses and maintains supply reliability, giving distributors confidence that they can safely deliver latex, nitrile, or vinyl gloves to their customers.

Contact Us