If you have ever used a reusable shopping bag, a wet wipe, or a face mask, you have used a non-woven fabric. People often ask me if these materials are biodegradable. The answer is not a simple yes or no.

In this guide, I will explain everything in simple terms. You will learn about the different non-woven fabric materials, which ones break down, and how to choose the best option for our planet.

Are Non-Woven Fabrics Biodegradable? My Take on How They Break Down

From my experience, this is the most important question, and the direct answer is: Most are not, but some can be.

To truly understand, we need to look at the science of how things break down. Biodegradation is a natural process where tiny microorganisms, like bacteria and fungi, eat a material and turn it back into basic natural stuff like water, carbon dioxide, and compost. It’s like how a fallen leaf slowly disappears into the soil.

The problem is that most non-woven fabrics are made from materials that these tiny microbes cannot digest. It’s like trying to eat plastic—our bodies can’t do it, and neither can theirs.

1. The Type of Fiber in Non-woven Fabric: This is the #1 Factor.

The most important thing to check is what non-woven fabrics are made of.

Synthetic Fibers (PP, PET, PE):

These are man-made plastics from petroleum. Think of them as solid oil. Microbes have never evolved to eat oil or plastic, so they leave it alone. These materials are not biodegradable. They might break into smaller pieces from sun and wind (this is called photodegradation), but they never truly return to nature. They just become microplastics.

-

A Note on “Biodegradable PP”:

You might see products labeled as such. This typically involves adding special ingredients to polypropylene to encourage breakdown. However, the rate is very slow. Lab tests under ideal conditions (ASTM D5511-18) show about a 6.53% biodegradation rate after 45 days. In the real world, I’ve seen these products might break down over 1 to 5 years under specific conditions, but they are not a quick or complete solution.

Natural Fibers (Cotton, Hemp, Jute, Wood Pulp):

These come from plants. Plants are made of cellulose and lignin, which are like candy for microbes. These materials are easily biodegradable. I recommend them because they break down well and can enrich your compost. Cotton, for instance, decomposes rapidly in a home compost setting.

Biopolymers (PLA, PHA):

This is a tricky middle ground. PLA is made from plants (like corn), so it’s not from oil. However, it’s processed into a plastic-like material. Microbes can break it down, but only under very specific, hot conditions found in industrial composting facilities. For instance, PLA-based non-wovens can decompose into water and CO₂ within weeks to months in the right setting. So, it is not biodegradable in your garden, home compost, or the ocean.

2. Chemical Treatment in Non-woven Fabric:

Sometimes, even a natural fiber fabric might not break down easily. Why? Because of the chemicals added to it.

Many fabrics are treated to make them waterproof, stain-resistant, wrinkle-free, or antibacterial.

These chemicals can poison the microbes or create a barrier that stops them from reaching the fibers.

So, a 100% cotton wipe that has been treated with a strong antibacterial chemical might biodegrade much, much more slowly than an untreated one.

3. The Environment: Where Non-woven Fabric Ends Up

Where the non woven product ends up matters a lot. Biodegradation needs the right conditions:

Industrial Compost: Perfect! It’s hot, moist, has plenty of oxygen, and is full of hungry microbes. This is where PLA and treated natural fibers can break down.

Home Compost: Good for untreated natural fibers. It’s cooler and less controlled, but perfect for cotton, hemp, and paper.

Landfill: Terrible. Landfills are often tight, dry, and lack oxygen. Things buried deep down don’t decompose well, even “biodegradable” items. A head of lettuce can stay intact for decades in a landfill.

Ocean or Soil: Natural fibers will break down here. Plastics will not; they will just crumble into microplastics and pollute the environment.

What Science Says About Non-woven Fabric Biodegradation? (Real Data)

In my research, I’ve seen tests that prove this:

A study buried a non-woven fabric made from ramie (a plant) and cotton in soil. It lost over 4% of its weight every day at the beginning and was almost two-thirds gone after 60 days.

Another test on a pure wood pulp (viscose) non-woven showed it lost 77% of its mass in just 72 days.

In contrast, tests on 100% PLA show it barely breaks down in normal compost. It needs that industrial heat to get started.

Field trials leaving jute and hemp mats outside over winter showed they were significantly broken down within 180 days.

Answer: Is Your Non-woven Fabric Biodegradable?

So, is your specific non-woven fabric biodegradable?

-

If it’s a standard reusable shopping bag, a face mask, or a wipe that feels like plastic, it is almost certainly made from polypropylene (PP) and is NOT biodegradable.

-

If it’s a soft, cloth-like wipe that feels like a natural towel, it might be made from viscose or cotton and IS biodegradable.

-

If the package says “compostable” and has a certification logo (like OK compost HOME), then you can trust it IS biodegradable under the right conditions.

Always remember: “Biodegradable” is a claim that needs proof. Look for the certification logos to know for sure.

Environmental Impact of Non-Woven Fabric

I’ve seen how non-woven fabric waste creates big pollution problems around the world. About 66% of these products come from synthetic materials. These materials don’t break down. In my experience, they stay in our landfills and environment for years, making the global waste problem worse.

How Non-woven Fabrics Harm Nature?

From what I’ve studied, the textile industry, including non-wovens, causes a lot of harm. It’s behind up to 10% of global carbon emissions and 20% of water pollution from its dyeing and finishing. Each year, about 85% of all textiles go straight to a landfill. I believe items we use once, like wipes, masks, and hygiene products, are a big part of this waste. This puts more stress on our environment.

Microplastics and Their Lasting Harm

I find that non-woven fabrics from synthetic fibers, like polypropylene, create huge amounts of microplastic pollution. Think about this: washing just one load of laundry with polyester non-wovens can send 700,000 microplastic fibers into our water. These tiny fibers flow into our rivers, lakes, and oceans. Every year, over half a million tons of microplastics from textiles end up in the ocean. Plant-based non-wovens do release more fibers in water, but I’ve learned they break down much faster than the synthetic kind.

Disposable vs. Reusable: My Take

Disposable non-wovens like wipes and face masks are convenient. I get it. But most are made from materials that don’t break down naturally. This creates long-term pollution in our land and water.

I suggest choosing reusable or recycled non-wovens to lessen this impact. For instance, some European companies now use over 30% recycled polyester fiber in their non-wovens. Plant-based options like hemp, jute, or kenaf are even better because they can be composted, but they are not widely available yet.

Polypropylene non-wovens are the most common. They use up to one-third less resin than other plastics. They can also be ten times more biodegradable, but this requires specific conditions. From my experience, these conditions are rarely met in reality.

What the Numbers Tell Us?

I’ve looked at the data, and it’s clear: global use of non-woven fabric grew from 11.2 million tons in 2019 to an estimated $64.8 billion in 2024. This rapid growth also means we have a bigger waste problem.

Some better options are appearing. These include plant-based non-wovens and fabrics made from recycled polyester. A key point to remember is that many “bioplastics” decompose in industrial composters, not in a landfill or the ocean.

Producing and throwing away non-wovens creates a large carbon footprint. To put it in perspective, I learned that making one cotton T-shirt takes 2,700 liters of water. That’s enough drinking water for one person for almost three years.

Testing Non-Woven Fabric Biodegradability

I wanted to know if non-woven fabrics really biodegrade. I found that scientists have specific ways to test them. Based on my research, the results depend a lot on the fabric’s fiber makeup. We now have standard test methods that give us clear and comparable information.

My Favorite Test Methods for Non-Woven Fabric Biodegradability

Composting Tests: I find this method very practical. Scientists bury fabric samples in compost and soil. They then track how much oxygen the fabric consumes as it breaks down. They use devices like OxiTop® to monitor this activity. By measuring the weight loss, we get a clear percentage of how much material biodegraded.

Laboratory Disintegration Tests: In this test, scientists place the nonwoven fabric in a special reactor for at least 45 days at a steady temperature. The amount of material left over shows how much the fabric broke down into tiny pieces. I believe this is a key first step in the biodegradation process.

Microscopy & Elemental Analysis: I suggest looking at the microscopy images. Scientists use powerful tools like SEM (scanning electron microscopy) and EDS (energy-dispersive spectroscopy) to inspect fibers before and after testing. For example, these tools show that cotton and feather fibers break down almost completely in 24 weeks, while PLA fibers often stay intact.

Key Standards I Follow for Testing Non-Woven Fabrics

For reliable and repeatable data, I recommend following these international standards:

– ISO 14855: This tracks how plastics and composites biodegrade in controlled compost conditions. It measures CO₂ release and oxygen use.

– ASTM D5338: This is similar but focuses on measuring the CO₂ output from biodegrading plastics in compost.

– EN 13432: I use this one for packaging. It lays out the rules for what can be called compostable and biodegradable.

Here are the key things I track during these tests:

– The biodegradation percentage (%)

– Weight loss after the test

– Oxygen or CO₂ release

– Changes in fiber structure seen under a microscope

– Changes in elements, like sulfur loss from feathers, using EDS

My Experience with How Different Non-Woven Fabrics Perform

PLA-Based Nonwovens: From my tests, 100% PLA nonwovens show almost no decomposition in standard compost. However, I found that when you blend PLA with cotton or feathers, the fabric breaks down much better. For example, after a 24-week test, the fibers in a blend were gone, but most of the PLA was still there.

Nonwovens With Natural Fibers: Based on my experience, samples made from just cotton, kenaf, or bagasse degrade faster and more completely than synthetic ones. They pass the disintegration and biodegradation tests. I’ve also found they can have physical properties similar to some biodegradable polyester composites.

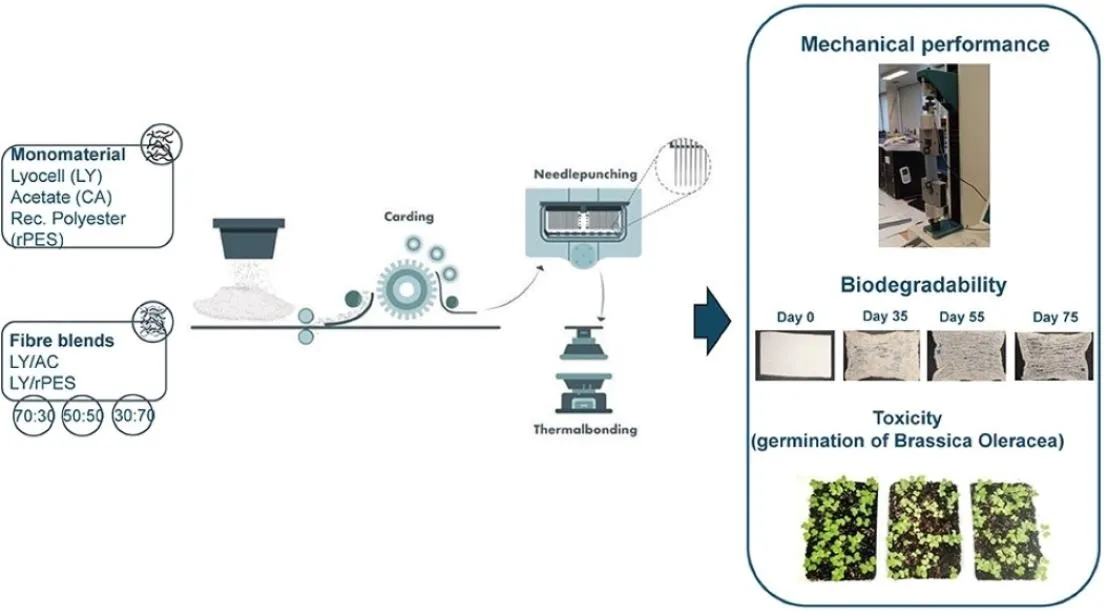

Lab Results from The SUSTAFIT Project: A great example is the SUSTAFIT project. Their 45-day composting tests showed impressive breakdown for many nonwoven fabrics. The best results came from fabrics with high plant-based content.

My Key Takeaways on Non-Woven Fabric Biodegradability Testing

- The more natural fibers, like cotton or feathers, the faster and more completely the fabric degrades. I always recommend blends with high natural content.

- In my experience, testing takes about 45 days for lab composting and can go up to 24 weeks for tests with imaging.

- The results I watch for are total weight loss, the disappearance of certain elements, and how the fibers break down under a microscope.

I believe these scientific tests are vital for correctly labeling non-woven fabrics as biodegradable or compostable. They show why the fiber makeup of a product is so critical to its real-world environmental impact.

Eco-friendly Options and New Ideas for Non-woven Fabric Material

From my experience, biodegradable non-woven fabrics are changing how we think about environmental protection. These materials use bio-based polymers like polylactic acid (PLA) and polyhydroxyalkanoate (PHA). Both come from resources that can grow back, like plants. When you throw them away, tiny organisms break them down into carbon dioxide and water. I also think natural plant fibers like cotton, flax, and hemp are great options. They break down fast and have other benefits, like absorbing moisture and feeling soft on the skin.

Where I See Biodegradable Non-Wovens Used

You can find these green materials in many common items. I suggest you look for them in:

– Eco-friendly shopping bags

– Agricultural mulch and seedling covers

– Compostable packaging

– Hygiene and medical products (like diapers, wet wipes, masks, and bandages)

Using these products in our daily lives can help reduce long-term plastic pollution.

How These Non-Woven Fabrics Help Create a Circular System

I think it’s great that sustainable non-woven fabrics do more than just break down. They also feed into a system of reuse.

– You can compost used PLA-based items at home or in special facilities. This turns waste into helpful soil nutrients.

– Recycling programs can change old non-wovens into insulation, geotextiles, and even construction supplies.

– I’ve noticed several manufacturers now use recycled plant fibers or polymers to create new non-wovens, which closes the production loop.

– In my farming work, I recommend biodegradable non-woven mulches because they return nutrients to the soil. This supports one crop cycle after another.

New Tech Making Non-Woven Fabrics More Sustainable

Modern technology is improving how these non-woven fabric materials work.

– Enzymatic degradation: Custom enzymes break down synthetic polymers in non-wovens very fast. This method uses less energy and speeds things up.

– Electrospinning & nanofiber technology: This technique produces finer and stronger fabrics that are also more biodegradable. I think they are beneficial for filtration and healthcare.

– Additive-enhanced non-wovens: With new additives, traditional PP can now break down within five years under the best conditions.

– Compostable spunlace and flushable non-wovens: I believe these new wipes and sanitary items are a game-changer. They dissolve without harm after use, which cuts down on pollution in landfills and our water.

Real-World Examples and Data

Here is some data from my research:

– Biodegradable PP non-woven fabrics: They show a 6.53% biodegradation after 45 days in lab tests.

– Industrially compostable PLA non-woven fabrics: These can completely decompose into water and CO₂ within weeks to months.

– Compostable spunlace non-wovens: I suggest looking for these, as they are now standard in many popular wet wipe brands.

In my opinion, biodegradable non-woven fabrics are the future of eco-friendly design, particularly those made from plant fibers and bio-based polymers. Using new technology, better recycling systems, and smarter material choices is a powerful combination. I feel these fabrics are a significant step forward in reducing the environmental impact of everyday textiles.

Best Practices for Using and Disposing of Non-Woven Fabrics

In my opinion, choosing the right non-woven fabric can really help the environment. About 66% of non-wovens are synthetic. This means they can last for decades if you don’t dispose of them correctly. I suggest switching to fabrics made from plants, like hemp, jute, or recycled polyester. This is a great way to reduce your impact on the planet.

Tips for Businesses and Consumers

Businesses:

I recommend sourcing non-woven fabrics made from recycled or plant-based fibers, like recycled polyester or PLA.

You should reduce single-use packaging. I think offering reusable nonwoven options is a much better choice.

I also suggest you create programs for customers to return or recycle old nonwoven products.

It’s a good idea to use simple labels. You can also show customers the best ways to recycle and dispose away items.

Consumers:

I suggest choosing reusable nonwoven bags over disposable ones.

You can recycle non-woven fabrics in some areas. I advise checking with your local recycling center for their rules.

Please don’t flush wipes down the toilet. They release tiny plastic particles that pollute our water.

I recommend you wash nonwovens only when necessary. Use a gentle wash cycle to reduce the release of tiny fibers.

Look for products that are certified to break down naturally. Be sure to follow the disposal instructions on the package.

Impact and Recycling Data

The nonwovens market grew from 11.2 million tons ($46.8B, 2019) to a forecasted $64.8B by 2024.

Over 30% of polyester fiber used in Europe is now recycled.

Correct recycling and composting can keep billions of tons of nonwoven waste out of landfills.

Conclusion:

So, let’s go back to the original question: Is non-woven fabric biodegradable?

The answer is: only if it is made from the right stuff.

-

NO: If it is made from plastic like PP, PE, or PET.

-

YES: If it is made from natural fibers like cotton or hemp. These can break down in your garden.

-

YES, BUT…: If it is made from PLA. It will biodegrade, but only if sent to a special composting facility.

The most important thing is to be a smart shopper. Look past the marketing words and check what the product is actually made of. Choose reusable options when you can, and when you can’t, choose compostable materials. Together, we can help reduce plastic waste and keep our planet clean.