I’ve heard many workers ask if they can reuse their disposable coveralls after a quick job. It feels wasteful to throw them away when they still look clean. But reusing disposable coveralls can quietly raise safety risks and costs you don’t expect. Let’s look at what really happens after the first use — and what safety rules say about it.

Can You Reuse Disposable Coveralls?

I strongly advise against reusing disposable coveralls labeled as single-use PPE. Based on my experience, this practice creates serious health and safety risks. Here are the main reasons why I recommend never reusing these garments:

Why Reusing Disposable Coveralls Is Unsafe?

Compromised Protection:

After you wear them once, the material and seams start to break down. The double-sided tape on zip covers loses its grip. This makes the suit less able to block dangerous substances.

Ongoing Contamination:

Germs and harmful chemicals stick to the suit’s surface after use. I’ve seen how reusing a dirty suit spreads these agents to new places. This puts you and the people around you at higher risk.

Material Breakdown:

Most disposable PPE coveralls use polyethylene film or SMS fabric. Makers design these materials for one use. They break down fast if you wear them again. The pores get bigger. Harmful particles get through more easily. The fit gets worse—elastic cuffs stretch out.

Supporting Data and Compliance Requirements

Bacterial Filtration Efficiency (BFE):

Disposable SMS coveralls offer up to 95% BFE. Reusable garments drop from under 70% to less than 40% BFE after you wash them multiple times. This shows how protection falls off when you try to make garments last longer than they should.

OSHA and NFPA regulations:

These standards are clear. Chemical protective clothing marked ‘disposable’ must not be reused. Workplace safety laws require this.

Real-World Examples and Industry Protocols

Healthcare and Pharma Sectors:

Hospitals must use disposable medical coveralls once, then throw them away. This limits infection exposure. It also meets regulatory compliance, which I find critical during outbreaks.

Cleanroom Environments:

In Grade A/B cleanrooms, even small mistakes from reuse cause contamination. You can fail to meet industry regulations.

Hospital and Biolab Practices:

I recommend following what top institutions do. They throw away disposable PPE after each use. They bag them right away for safe disposal. They never clean or reuse these garments.

Risks Associated with Reuse

Weaker barrier against chemicals, germs, and dangerous particles

Loss of strength and tear resistance, which increases the chance that the suit will fail

Hidden damages you can’t see, such as tiny scratches and weak seams

You cannot clean the material well enough, or trust the cleaning process

Higher risk of spreading contamination while putting on or taking off reused coveralls

International Standards for Disposable Coveralls

- EN ISO 13982-1:

This standard identifies disposable coveralls as “Type 5” and “Type 6” PPE. Both are single-use. They protect against particles and limited liquid splashes.

In summary,

every major safety authority and regulation confirms this: makers do not design or approve disposable coveralls for reuse. The dangers are clear. Reduced barrier performance, contamination, and legal problems outweigh any benefit from using them more than once. I suggest you always use fresh coveralls for each task.

Engineering and Material Science of Disposable Coveralls

Disposable protective coveralls serve one purpose: single use. I recommend them for quick barrier protection against contaminants. They are lightweight and cost-effective. Most use non-woven synthetics. Common materials include polypropylene (PP), polyethylene (PE), SMS polypropylene, or Tyvek.

Core Materials and Protective Features

- Polypropylene (PP):

This material is light, breathable, and resists chemicals. I see it used in healthcare, labs, and cleanrooms. It blocks dust and safe particles well. PP reduces heat stress and prevents static buildup. But it won’t protect you from strong chemical splashes. - Polyethylene (PE):

Manufacturers coat PP with PE to boost liquid resistance. This works well for areas needing extra liquid protection. - SMS Fabric:

This is a multi-layer non-woven material. It filters particles better than PP alone. SMS blocks fluids and particles effectively. I suggest it for high-risk medical or industrial zones. - Tyvek (HDPE):

Tyvek resists dangerous particles and liquid splashes better than other options. You’ll find it in asbestos removal or chemical work. But Tyvek is made for one use only. It breaks down after exposure or cleaning attempts.

Performance Limits and Single-Use Design

Disposable coveralls cannot be cleaned or reused. Contaminants, stress, or moisture break down the fibers fast. This ruins their protection.

Seams and closures work for limited, controlled use. They fail under repeated cleaning—mechanical or chemical.

Industry rules say: dispose after exposure. This stops cross-contamination. It also prevents users from trusting worn-out gear for protection.

Comparison With Reusable PPE

Reusable PPE:

These use cotton-polyester blends, treated woven fabrics, or polyurethane coatings. Based on my experience, they survive many cleaning cycles and heavy use.

Reusable coveralls offer stronger protection. They resist tears and punctures better. They use multi-layer construction for dangerous environments.

You can autoclave them, wash them at high temperatures, and disinfect them with chemicals. Disposable coveralls cannot survive this.

Key Specifications and Industry Data

Typical weight of Polypropylene coveralls:

30–50 gsm (grams per square meter).

Particle filtration for PP coveralls:

They block over 90% of 1–2 micron particles. I like them for dry, dusty environments. But they are not certified for dangerous biological or chemical agents.

Usage cycle:

Manufacturers say: use for one shift or one exposure, then replace. This is standard in cleanrooms and hospitals.

Cost details:

Disposable coveralls cost 30–60% less per unit than reusable ones. But frequent changes add up. Over time, they may cost more.

Anti-static properties:

These protect sensitive electronics. They reduce fire risk from static discharge near flammable materials.

Common Application Scenarios

- Healthcare:

Workers change PP coveralls fast between patient areas. This controls infection spread. - Asbestos abatement:

Tyvek suits work for one-time entry and exit in contaminated zones. - Food processing:

PP coveralls stop cross-contamination. They prevent fiber shedding in processing areas.

In summary, Disposable coveralls focus on short-term barrier protection and fast replacement. Their non-woven structure and seam design differ greatly from reusable PPE. Reusable gear handles multiple cleanings and long-term use. Disposable options do not.

Safe Removal and Disposal of Used Disposable Coveralls

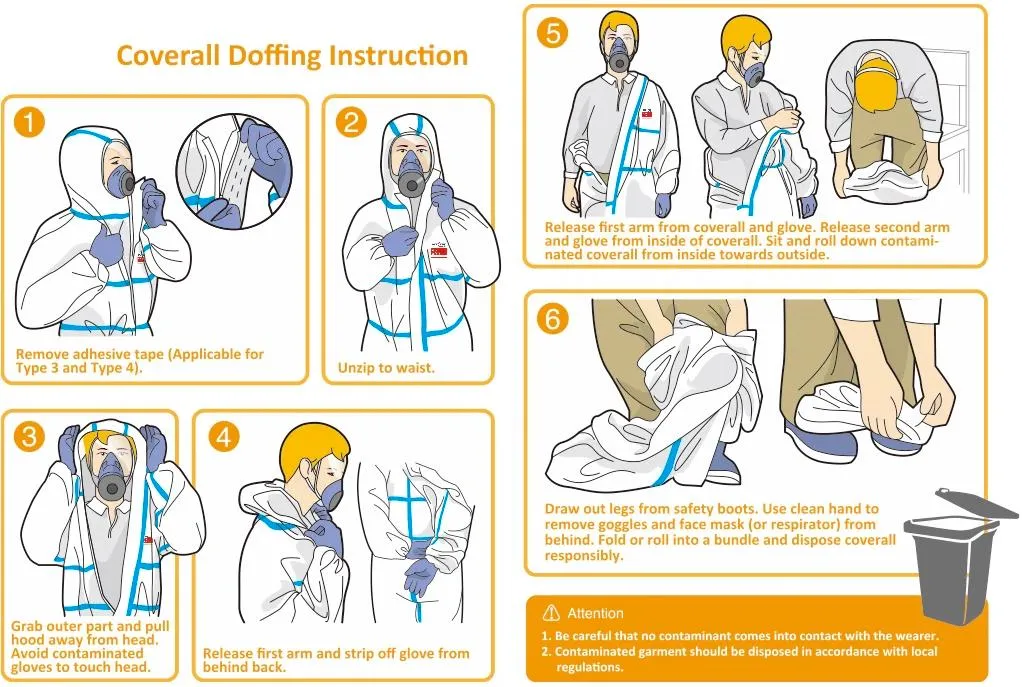

You need to remove and dispose of used disposable coveralls the right way. This protects you and others from contamination. Here’s my step-by-step guide based on what works in the industry:

Step-by-Step Removal Procedure

- Stand in a designated removal area, next to a hazardous materials waste bin.

- Remove gloves first. This cuts down the chance of spreading contaminants from your hands.

- Wash your hands right after removing gloves. Do this before touching other PPE.

- Peel the coverall off from the hood and shoulders. Roll it inside out as you go downward. Don’t touch the outside surface.

- Put the safety coverall straight into a designated waste bin. Never let it touch clean surfaces.

- Seal the waste bag tightly. I suggest double-bagging if you need to prevent leaks.

- Wash your hands well after removal and disposal.

How to Dispose of Contaminated Coveralls?

- Sort used coveralls as hazardous or general waste. Coveralls from healthcare, labs, or hazardous sites need biohazard waste handling.

- Put contaminated PPE in regulated medical or hazardous waste containers. Match the container to the exposure type: healthcare, chemicals, or pesticides.

- In OSHA/EPA industries, Remove coveralls in a decontamination chamber. Seal them in a bag. Dispose of according to local and federal hazardous waste rules.

- No regulations in your area? Treat coveralls as household hazardous waste. Take them to authorized collection sites.

- Final disposal usually means incineration or specialized treatment. This prevents environmental harm.

Key Facts and Real-World Examples

Tens of thousands of workers change disposable coveralls multiple times a day.

CDC and FDA require medical and lab coveralls to go into biohazardous medical waste.

Poor disposal adds to landfill waste. Disposable coveralls take centuries to break down.

Incineration must happen at controlled facilities. This prevents toxic emissions.

Healthcare: Coveralls with blood or body fluids go in red-labeled biohazard bins. Contractors manage the incineration.

Mold remediation: Remove and bag coveralls in a decontamination chamber. Dispose of them as hazardous waste.

Agriculture: Follow chemical/pesticide label and regulatory guidance. No guidance available? Treat as hazardous waste.

Scenarios That Prohibit Reuse of Disposable Coveralls

In some high-risk environments, you cannot reuse disposable coveralls. It’s unsafe. In fact, it’s forbidden. Safety standards and industry rules require single-use protocols in these scenarios:

Asbestos Removal Coveralls

Never reuse disposable coveralls during asbestos removal. Asbestos fibers are dangerous. They cling to clothing after just one use. Workers must wear a fresh coverall for each entry or shift.

Example: During asbestos removal projects, workers discard coveralls as hazardous waste after every use. This prevents fiber transfer and protects respiratory safety.

Coveralls for Chemical and Hazardous Material Exposure

Toxic chemicals, pesticides, and biocides require protective barriers. Disposable coveralls prevent skin absorption and chemical burns. Once exposed to chemicals, the protective layer traps hazardous residues.

I recommend immediate disposal after use. Reused coveralls cannot prevent secondary exposures or cross-contact.

Example: Emergency personnel responding to chemical spills use a new coverall for each deployment. Even small invisible breaches can cause serious injuries.

Coveralls for Healthcare and Infectious Disease Control

Single-use medical coveralls are essential in medical fields, laboratories, and infectious disease zones. This includes COVID-19, Ebola, and MRSA treatment areas. Reusing garments risks spreading infections between patients, staff, and environments.

Example: Hospital workers treating Ebola patients dispose of their coveralls after every interaction. This avoids transmitting the virus.

Coveralls for Radioactive Material Handling

Coveralls exposed to radioactive contamination are for single use. Radioactive particles are almost impossible to remove from fabric. Reuse creates a life-threatening risk.

Regulatory agencies (OSHA, NIOSH) prohibit reuse in nuclear and radiology settings.

Coveralls for Cleanroom and High-Contamination Manufacturing

In the pharmaceutical and electronics sectors, even trace contamination from reused coveralls could ruin entire product lines or batches.

Based on my experience, new disposable non-woven coveralls are required for every entry into Grade A/B cleanroom zones. This protects against particulate and microbial contamination.

Coveralls for Fire, Extreme Heat, and High-Risk Industrial Work

Flames, molten metals, and extreme heat cause permanent damage to coverall materials. Hazardous substances can embed in the fabric during these tasks.

I suggest using a fresh, intact coverall for every high-temperature or fire-related task.

Key Data and Industry Guidelines

Disposable coveralls generate 94–96% more landfill waste compared to reusable options. But authorities prioritize user and community safety over environmental concerns in high-risk areas.

OSHA and NIOSH state that decontaminating disposable PPE for reuse is not effective or reliable in these hazardous environments. Single-use is mandatory.

Summary Table: Environments Prohibiting Reuse

| Scenario | Hazard Type | Reason for Prohibit Reuse | Example/Industry |

|---|---|---|---|

| Asbestos Removal | Fibrous particulates | Inhalation/cross-contamination risk | Construction/remediation |

| Toxic Chemicals | Chemical exposure | Absorption, poisoning, burns | Manufacturing/agriculture |

| Infectious Disease | Pathogens | Infection spread, outbreak control | Healthcare/laboratories |

| Radioactive Materials | Radiation | Permanent contamination | Nuclear/medical imaging |

| Cleanroom Environments | Particulates | Product contamination | Pharma/electronics |

| Fire/Extreme Heat | Thermal/chemical | Degradation, hidden hazards | Oil & gas/foundries |

In all of these scenarios, using a new disposable coverall for each task is mandated. It’s a safety requirement. Any attempt to reuse disposable coveralls in these environments increases danger for users, workplaces, and the surrounding community.

The Hidden Costs of Reusing Disposable Coveralls

Reusing disposable coveralls may seem like a way to save money. But the risks and long-term costs outweigh any immediate savings. Single-use coveralls are designed for limited use and reliable protection. Using them more than once damages their barrier capabilities. This leaves workers exposed to hazardous substances.

Economic and Regulatory Risks of Reuse

Medical Expenses:

Exposure incidents can result in direct costs of $5,000 to $20,000 per case. This includes treatment and lost productivity.

Productivity Losses:

Workers get injured or become ill. Work stoppages and unexpected downtime follow. Companies lose thousands each time.

Regulatory Fines:

Non-compliance with safety standards like OSHA or HSE brings fines. These range from hundreds to tens of thousands of dollars per violation.

Data-Driven Outcomes

Industry data shows that proper single-use PPE practices reduce workplace risks by up to 37.6%.

Trying to clean or reuse disposable coveralls can cost $3–$10 per attempt. You often get no restoration of full protection. This may exceed the price of buying a new one.

The average cost for a new disposable coverall is $2–$8. A single contamination event in a cleanroom can result in multi-day shutdowns. Losses can reach tens or even hundreds of thousands of dollars.

Cost-Effectiveness of Single-Use Protocol

- Single-use eliminates contamination spread. It reduces expensive incidents.

- Reusable PPE saves money if designed for repeated use and proper laundering. Disposables never deliver this benefit.

- Key figure: Risk reduction up to 37.6% with adherence to single-use protocols.

In summary:

The price for a new disposable coverall is minimal. Compare this to the financial, legal, and human health risks of reuse. Based on my experience, proper single-use of disposable coveralls is the most cost-effective approach for any safety-driven environment. I recommend this as the responsible choice.

Cost and Sustainability Comparison: Disposable vs. Reusable Coveralls

I recommend evaluating protective clothing for your facility based on two key factors: cost and environmental impact. Industrial laundry services have made reusable cleanroom coveralls a smart choice in many sectors.

Cost Efficiency and Service Life

Reusable coveralls last about 50 cycles on average. Sterilized versions handle 40 cycles. Non-sterilized types go for 60 cycles. Some non-sterilized coveralls reach 75–100 cycles before retirement.

I like the cost savings here. Reusable costs 58% less than disposable options. This includes all garment purchases and laundry expenses.

Based on industry data, facilities save $120 million per year by choosing reusable cleanroom coveralls and using industrial laundry services.

Environmental Impact: Reusables vs. Disposables

Reusable use 56% less natural resources. They produce 57% lower carbon dioxide (CO₂) emissions compared to single-use options.

Facilities using reusable coveralls cut water usage by 77%. Solid waste drops by 95%.

Disposable HDPE options beat PP disposables. They reduce energy use by 43%. CO₂ output drops by 41%. But both fall short compared to reusables for the environment.

Practical Tips for Facility Managers

High-use environments gain the most benefit. Sites with constant protective clothing needs hit the break-even point fast when they switch to reusables.

About 40% of reusables need laundering and sterilization after each wear. The other 60% need just laundering.

Facilities requiring gamma sterilization can use reusables. Modern laundry services handle this need.

The Reuse Cycle and Lifecycle Extension

- Professional laundry services handle everything. They wash, package, manage wastewater, and sterilize as needed.

- Reusables don’t go straight to the landfill after their primary service ends. They move to secondary uses. This extends garment life beyond the initial 50 cycles on average.

My recommendation:

I suggest facilities with ongoing protective wear needs shift from disposable to reusable cleanroom coveralls. You’ll see lower costs. You’ll reduce your environmental footprint. Professional industrial laundry and sterilization services make this switch easier and more effective.

Frequently Asked Questions For Disposable Coveralls

Q1: Can disposable coveralls be washed?

No. Disposable coveralls are not designed for washing. Water, detergent, or heat can damage the protective coating and seams, making them unsafe for reuse. Even if they look clean, their barrier performance drops quickly. To stay protected, always replace them after one use instead of trying to wash or disinfect them.

Q2: How long can I wear one disposable coverall?

It depends on the job and exposure level. Most disposable coveralls are made for one continuous shift or single use. Once the suit becomes torn, wet, or dirty, it should be replaced immediately. Wearing it too long can reduce its protection against dust, fluids, or harmful particles.

Q3: Are reusable coveralls safer?

Reusable coveralls can be safe if they are properly maintained and washed in controlled conditions. They’re made from stronger fabrics and can last through several cleaning cycles. However, they need strict inspection after each use. For short-term or high-contamination tasks, disposable coveralls are still the safer option.

Q4: What’s the difference between Type 5 and Type 6 coveralls?

Type 5 coveralls protect against solid dust and particles, making them suitable for construction or asbestos work. Type 6 coveralls offer light liquid splash protection, often used in cleaning or laboratory tasks. Choosing the right type depends on the level of exposure and safety requirements in your job.

Q5: How should disposable coveralls be stored before use?

Store them in a clean, dry, and ventilated area away from sunlight or chemicals. Avoid crushing or folding them tightly, as this may damage the seams or coating. Proper storage helps keep their barrier protection intact until you’re ready to use them on site.

Final Thoughts and Recommendations

Every major safety standard—from OSHA to EN ISO—confirms that disposable coveralls are for one-time use only. The hidden risks of reuse outweigh any short-term savings.

From my own experience, the smartest and most responsible practice is simple: use a new disposable coverall for every task. This keeps your team safe, meets compliance, and prevents costly contamination events.

If your facility needs custom-made disposable coveralls, contact us for a detailed quotation and product recommendation. We can help you select the right PPE solution for your environment and compliance level.