Being around hazardous materials is risky. From chemicals to germs, even small mistakes can be serious. HAZMAT suits act like a shield, keeping your body safe. I’ve seen how the right HAZMAT suit makes a big difference for workers and first responders. This guide will explain the main HAZMAT suit levels, what they protect against, and when each type is needed.

What is a HAZMAT Suit? Understanding the Basics and Key Risks

From my experience, a HAZMAT suit is a specific type of personal protective equipment (PPE). I see it as a shield that protects people from dangerous materials and substances. The suit’s main job is to create a barrier. This barrier protects your skin, eyes, and breathing from contact with chemicals, germs, or radioactive materials. I think it’s crucial that in high-risk scenarios, this protection can even stop damage to your internal organs.

I see these professionals use HAZMAT suits often:

– Firefighters

– Emergency medical teams

– Paramedics

– Hazmat specialists

– I’ve worked with industrial crews who face toxic work areas.

– I also see researchers use them when they handle infectious or radioactive items.

Main Hazards HAZMAT Suits Are Designed For

- Chemical Hazards:

In my view, a suit must protect against chemicals like toxins, acids, and fumes. I recommend a suit for industrial spills, accidental leaks, or attacks with chemical weapons. - Biological Hazards:

The suits must also block germs like bacteria, viruses, and spores. I believe this is vital during disease outbreaks or bioterrorism events, such as the Ebola or COVID-19 responses. - Radiological Hazards:

Some suits offer protection from radioactive particles. I find this is key for nuclear industry workers or first responders in a radiological event. My advice for high-level radiation risks is to use lead-lined suits.

In my professional opinion, not using the correct HAZMAT suit for a specific risk is a huge mistake. It can lead to severe injuries, such as burns, infections, breathing failure, or death. This is why I always stress that you must understand the exact danger. You need to know its strength and your expected exposure time to select the right protection.

A Guide to EPA’s HAZMAT Suit Levels

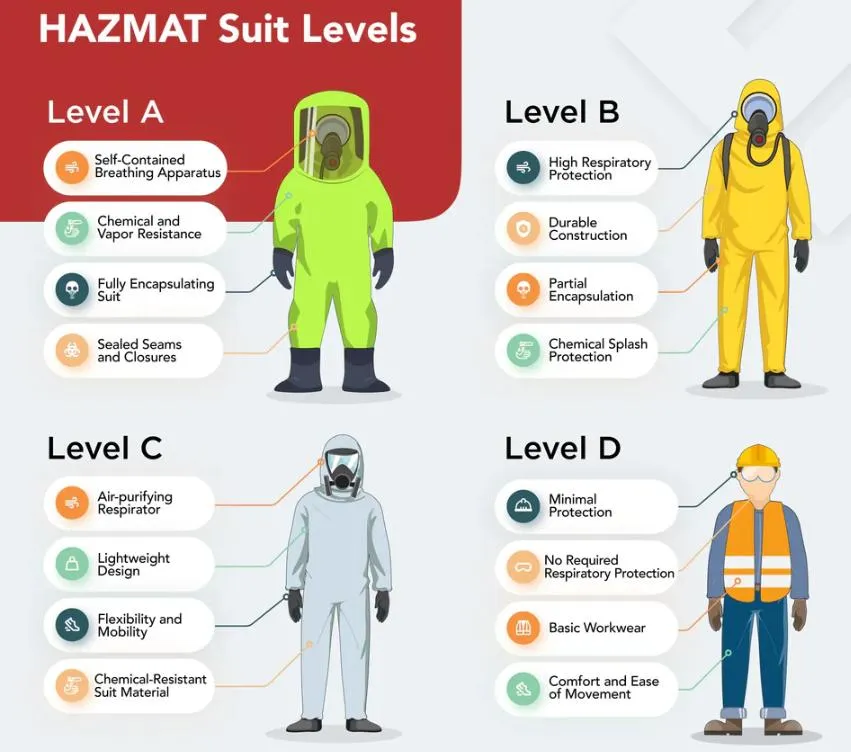

The EPA sorts HAZMAT suits into four main levels: Level A, Level B, Level C, and Level D. I find it helpful to think of each level as a response to a specific risk. These risks can be chemical, biological, or radiological. The level determines the gear you need to protect your skin, eyes, and lungs.

Level A HAZMAT Suit: Maximum Protection for Extreme Hazards

Level A HAZMAT suits offer the most protection. They are completely sealed and used with a positive-pressure, full-face breathing apparatus (SCBA). I recommend this setup when there is a major risk to the skin and lungs from chemicals, biological agents, or radioactive particles. A standard Level A outfit includes chemical-resistant gloves (inner and outer) and boots.

Best for: I suggest using them for major chemical spills, releases of unknown materials, or bioterror events in spaces with bad air circulation.

Real risks: The dangers are toxic vapors and hazardous liquids. Airborne particles can also harm your skin or organs.

Notable point: I always stress that these suits can weigh up to 50 pounds (22 kg). This causes heat stress, so users must take regular breaks.

Cost: A complete Level A suit with an SCBA costs about $2,000–$3,000 per set.

Decontamination: After use, the suit needs an intense shower and air monitoring.

Scenario Example: A chlorine gas leak at a chemical plant, or transporting a patient with the Ebola virus.

Level B HAZMAT Suit: High Respiratory Protection with Less Skin Coverage

Level B HAZMAT suit prioritize keeping your lungs safe with an SCBA. Based on my experience, the suit itself is less sealed than Level A. It’s a hooded suit that protects from chemical splashes rather than vapors.

Best for: I recommend Level B when you know the chemical involved. The main risk should be from liquids, with a lower threat from vapors.

Typical Scene: You might see them used for environmental spill cleanups, treating contaminated groundwater, or handling ammonium tank leaks.

Cost: These are cheaper than Level A, but the breathing gear is often the same.

User Base: Over 340,000 U.S. emergency responders receive training for Level A and B situations, according to the Department of Homeland Security (2022).

Level C HAZMAT Suit: For Known Hazards with Controlled Airborne Risks

I choose Level C HAZMAT suits when I know the specific contaminant and its concentration. This level works only if an air-purifying respirator (APR) is enough to handle the threat. They protect against splashes but are not safe for unknown or highly toxic vapors.

Best for: You can use these in places with low-to-moderate toxicity. The airborne risk must also be limited and closely watched.

Ensemble: The gear includes liquid splash-protective clothing, an APR, gloves, and boots.

Usage: I’ve seen them used for mold removal or cleaning up pesticides where exposure is tracked.

Cost: The cost is lower than Level A and B because the equipment is less complex.

Level D HAZMAT Suit: Basic Barrier for Minimal Hazards

Level D HAZMAT suit provides basic protection. It includes coveralls, boots, and eyewear. It’s important to know there is no breathing protection. I suggest using this for simple jobs in safe areas with no significant exposure risks.

Usage Examples: This could be for building demolition, standard maintenance, or working around non-hazardous dust.

Cost: A full set is almost always less than $100.

Quick Comparison Table: HAZMAT Suit Levels

| Level | Respiratory Protection | Skin/Eye Protection | Typical Use | Example Scenario |

|---|---|---|---|---|

| A | SCBA |

Sealed, air-tight suit | Max unknown hazard | Chemical spill, bioterror event |

| B | SCBA | Splash-resistant suit | Liquids, less skin risk | Environmental cleanup |

| C | APR | Splash-resistant suit | Known, low air hazard | Mold or pesticide cleanup |

| D | None | Minimal (coveralls) | No real hazard present | Construction, maintenance |

Materials and Technology Behind HAZMAT Suits

From my experience, not all HAZMAT Suits are created equal. The material determines how well a suit protects you, how comfortable it is, and how long it lasts. Modern suits use specialized fabrics and laminates designed for specific hazards.

Polyethylene (PE) Suits

Many disposable HAZMAT Suits are made from high-density polyethylene (HDPE) or low-density polyethylene (LDPE).

- Pros: Lightweight, resistant to most liquids, cost-effective.

- Cons: Poor tear resistance, limited heat tolerance, not suitable for strong chemical vapors.

- Best use: Short-duration biohazard tasks, medical emergencies, or chemical splashes with low volatility.

I’ve seen hospital staff wearing PE-based coveralls during infectious outbreaks. They are easy to put on and take off, which is critical when time is limited, but they are not suitable for prolonged chemical exposure.

Polypropylene (PP) HAZMAT Suits

Polypropylene is another common material, often used in disposable or semi-disposable suits.

- Pros: Breathable, lightweight, good barrier against particles.

- Cons: Limited chemical resistance, not vapor-tight.

- Applications: Pharmaceutical labs, cleanroom maintenance, and minor contamination events.

Many PPE suppliers now combine PP with laminated films, which significantly improves chemical resistance without reducing comfort.

Laminates and Multi-Layer Composites

For Level A and B HAZMAT Suits, PPE suppliers often use multi-layer laminate fabrics. These layers may include:

- Outer chemical barrier: Usually butyl rubber or Tychem-resistant film.

- Structural support layer: Polyester or nylon for tear and puncture resistance.

- Inner comfort layer: Wicking or breathable layer to reduce heat stress.

These suits are heavy—often up to 22 kg—but they are essential for maximum protection against unknown chemical threats.

PTFE, PVC, and Specialized Coatings

Some suits are treated with PTFE membranes (like Tychem TK) to repel liquid chemicals and resist permeation. PVC coatings are excellent for acids and caustics. These materials increase durability and allow workers to clean and reuse suits multiple times if protocols allow.

Performance Metrics to Consider

When choosing a HAZMAT Suit, I always check these:

- Permeation Rate: How quickly a chemical passes through the suit material (mg/cm²/min).

- Breakthrough Time: Time before a chemical penetrates the suit. Longer times = better protection.

- Seam and Closure Resistance: Critical for preventing leaks at zippers, Velcro, or stitched areas.

A Level A suit may have a breakthrough time of 480 minutes for sulfuric acid, which is enough for an entire shift in industrial cleanup.

Key Industries and Applications for HAZMAT Suits

HAZMAT suits are vital in many industries. They protect workers from chemical, biological, and radiological dangers. Based on my experience, the demand for this gear is rising. This is due to stricter safety rules, industry growth, and greater awareness after recent global events.

Chemical and Industrial Safety: Manufacturing, Oil & Gas, Mining, and More

I find that hazmat suits are most used in chemical manufacturing, oil & gas, pharmaceuticals, and mining. Workers in these fields often face dangerous chemicals and vapors. Strong safety rules and the need to protect workers boost market growth. For instance, in 2024, the global hazmat suit market hit USD 8.26–8.34 billion. Most of this demand came from tasks needing chemical protection.

My analysis shows Level A HAZMAT suits provide top-tier protection. They are now required after large industrial spills or chemical accidents, particularly in refineries and big factories.

I’ve seen projections that the mining and metallurgy sector will increase its hazmat suit use by 6.9% CAGR through 2030.

Real-world examples show their importance. I think of EPA Superfund cleanups or plant explosion responses. Hazmat suits are essential in these cases.

Healthcare and Infectious Disease Control: Market Drivers and Examples

Based on the data, healthcare was the top industry in 2024, holding 26.76% of the market share. This shows a clear need for biohazard HAZMAT suits on the front lines. Hospitals, labs, and pharmaceutical plants use these suits for infection control, a must when handling contagious diseases and dangerous materials.

In my view, this is significant: Biohazard and infection control accounted for 52.56% of the U.S. hazmat suit market in 2024.

The demand for suits keeps growing. I believe this is because over 5,100 pharmaceutical companies are active in R&D. They currently have 18,600 drugs in development.

I recall that suit usage jumped globally during the recent pandemic. Hospital staff, lab techs, and medical transport teams all needed them.

For example, full PPE was vital during the Ebola and COVID-19 crises. It helped keep medical workers and patients safe.

Firefighting and Disaster Response: Protection in Extreme Conditions

From my experience, hazmat gear is essential for fire departments. They use it for chemical fires, industrial accidents, and train derailments. It’s also used for hazardous material rescues. Firefighters wear special heat- and flame-resistant suits during these dangerous events.

I suggest thinking about major events like plant explosions or chemical warehouse fires. These situations require airtight, full-body protection.

Fire crews in the U.S. are using these suits more often. They now follow strict standards for city and industrial settings.

Environmental Cleanup and Forensics: Waste Management and Crime Scene Safety

Certain jobs always need dependable HAZMAT suits. These include work at toxic waste sites, asbestos removal, and hazardous material disposal. I also recommend them for crime scene investigators and forensic teams. They use these suits when facing possible biological or chemical threats.

Both U.S. and EU standards require full-body protective gear for site cleanup.

I’ve noticed a trend. For longer jobs, comfort is key. This has led to more use of Level C suits for lower-risk situations. For high-risk cleanups, I suggest Level A/B suits.

Good examples are EPA Superfund site cleanups. Another is a hazardous crime scene where chemical or biological evidence might be present.

Based on my experience, hazmat suits are now a standard piece of equipment. They are used in any industry with chemical, biological, or radiological risks. I believe they are essential for protecting workers, both in daily tasks and during major emergencies.

Operational Best Practices: Donning, Doffing, and Decontamination

A HAZMAT Suit is only as effective as the way it is worn and maintained. Improper donning or doffing is a common cause of injury.

Donning (Putting on the Suit)

I recommend a step-by-step approach:

- Inspect the suit: Check for tears, missing zippers, or damaged seams.

- Put on base layers: Moisture-wicking undergarments help reduce heat stress.

- Boots and inner gloves: Ensure a snug fit to prevent gaps.

- Suit entry: Step into the legs carefully, avoiding snagging.

- Adjust hood and torso : Ensure the visor fits well and seals completely.

- Outer gloves: Cover cuffs and secure with tape or elastic.

- SCBA or PAPR: Check airflow and seals.

- Buddy check : Have a trained colleague confirm all seals and closures.

Doffing (Removing the Suit)

Removal is even trickier. I’ve seen contamination occur here more than anywhere else. Key steps include:

- Initial decontamination: Rinse off gross contaminants in a shower or using decontamination stations.

- Step-wise removal: Start with gloves, then boots, then suit, carefully folding inside-out.

- Respiratory device removal: Last, after leaving the contaminated zone.

- Disposal or cleaning: Single-use suits go to hazardous waste; reusable suits are cleaned according to manufacturer protocols.

Decontamination and Maintenance

- Chemical residues: Must be removed immediately to prevent permeation.

- Heat and UV exposure: Prolonged sunlight can degrade materials like Tyvek and PVC.

- Storage: Cool, dark, and dry areas extend shelf life.

- Inspection: Check seams, zippers, and gloves before every use.

From my experience, consistent training and rehearsals reduce mistakes by over 40% . Many accidents happen not because the suit fails, but because the user fails.

Cost Analysis and Global Supply Chain

From my experience, cost is a critical factor in HAZMAT Suit selection, especially for hospitals, industrial plants, and emergency teams with limited budgets.

Cost by Level

| Level | Approx. Cost (USD) | Key Notes |

|---|---|---|

| A | $1,500–$4,000 | Includes SCBA, fully encapsulated, highest protection |

| B | $500–$1,500 | Splash protection, SCBA outside, lower skin coverage |

| C | $200–$600 | Air-purifying respirator, splash protection, suitable for known hazards |

| D | $50–$150 | Minimal protection, basic coveralls, disposable or reusable |

Disposable vs. Reusable

- Disposable suits: Single-use, lighter, ideal for infectious outbreaks.

- Reusable suits: Durable, can withstand multiple decontamination cycles, cost-effective for industrial applications.

Example: A chemical plant may invest in Kappler Zytron suits, which can last 20–30 cycles with proper cleaning, while hospitals handling Ebola prefer single-use Tychem suits.

Global Supply Chain

Leading suppliers include:

- DuPont (USA): Tyvek and Tychem suits for chemical and biological protection

- Lakeland Industries (USA): ChemMAX and MicroMAX series for industrial and emergency use

- Kappler (USA/Global): Zytron and ChemMax Pro for reusable and disposable suits

- Ansell (Global): Offers both chemical gloves and integrated HAZMAT ensembles

I’ve noticed that during pandemic spikes or major chemical incidents, supply can become constrained, leading to price surges of 20–50%. Planning and maintaining stockpiles is essential.

Brand Comparison and Product Recommendations

From my hands-on research and field visits, here’s how I compare popular HAZMAT Suits:

| HAZMAT Suit Brand | Material | Levels Available | Notes |

|---|---|---|---|

| DuPont | Tyvek, Tychem | A, B, C | Excellent chemical resistance, widely trusted, disposable |

| Lakeland | ChemMAX, MicroMAX | B, C | Lighter, good comfort, reusable options |

| Kappler | Zytron | A, B | Durable, reusable, suitable for industrial high-chemical exposure |

| Ansell | Microgard | C, D | Cost-effective, good for low-risk and cleanroom applications |

Personal advice: For unknown chemical spills, always choose DuPont Level A; for low-risk cleaning, a Kappler Level C or Ansell Level D is sufficient.

FAQ: Common Questions About HAZMAT Suits

I’ve collected questions I often get from new responders and industrial workers:

1. Can HAZMAT Suits protect against nuclear radiation?

Not fully. They block radioactive dust and contaminated liquids, but gamma and neutron radiation penetrate most materials. Lead or specialized shielding is needed for high-radiation areas.

2. How long can I safely wear a Level A HAZMAT suit?

Heat stress limits use to 20–30 minutes per entry, especially in hot environments. Cooling vests can extend safe wear time.

3. What’s the difference between a HAZMAT Suit and a biohazard suit?

A biohazard suit is a type of HAZMAT Suit specifically designed to prevent viral and bacterial contamination. Chemical-resistant suits may not be fully bio-safe.

4. Can HAZMAT Suits be washed and reused?

Only certain reusable HAZMAT suits, like Kappler Zytron or ChemMax Pro, can be decontaminated for multiple cycles. Most disposable suits (Tyvek, Tychem) are single-use.

5. How do I know which HAZMAT Suit level to choose?

Perform a hazard assessment considering chemical type, vapor risk, airborne particle concentration, and exposure duration. Refer to EPA, OSHA, and NFPA guidance.

Final Thoughts

In my experience, HAZMAT suits are not optional—they’re essential for worker and responder safety. From chemical spills to pandemics, the right suit level can mean the difference between safety and severe harm. I believe success depends on three things: choosing the right level, consistent training, and strict decontamination.