Trusted Surgical Gloves Manufacturer In China

We are a leading surgical gloves manufacturer in China, producing high-quality latex and nitrile gloves for hospitals, clinics, and laboratories. Each pair meets international sterility and quality standards, with options for thickness, texture, and cuff length. Our factory supports OEM and private labeling services, full traceability, and stable production capacity to ensure a reliable supply for global buyers seeking trusted surgical gloves.

Best Surgical Gloves Supplier

Our factory delivers high-quality surgical gloves with a reliable supply for hospitals, clinics, and distributors. We offer latex and nitrile gloves with customizable thickness, texture, and cuff length. Every batch follows strict sterilization and quality controls, providing consistent performance and traceability. Buyers can access OEM services and flexible order quantities to meet diverse market needs efficiently.

Custom Surgical Gloves Made to Fit Your Needs

Material & Thickness Control

Our surgical gloves are manufactured using medical-grade nitrile or natural latex materials, with optional low-protein and reduced-allergen latex formulations. Surgical disposable gloves can be engineered with controlled thickness and gram weight to align with defined AQL standards and clinical barrier performance targets.

Surface Treatment & Ergonomic Fit

Surgical gloves are available with fingertip micro-texturing or full palm texture to support secure instrument handling. These surgical disposable gloves may be offered in powder-free polymer-coated or chlorinated finishes, with size coverage from 5.5 to 9.0 and choices of standard or extended cuffs.

Sterilization Process & Quality Assurance

Each production lot of surgical gloves can undergo EO or Gamma sterilization, validated to achieve a sterility assurance level of SAL 10⁻⁶. Surgical disposable gloves are routinely evaluated for pinhole integrity (AQL ≤ 1.5 or customer-defined) as well as tensile strength and tear resistance.

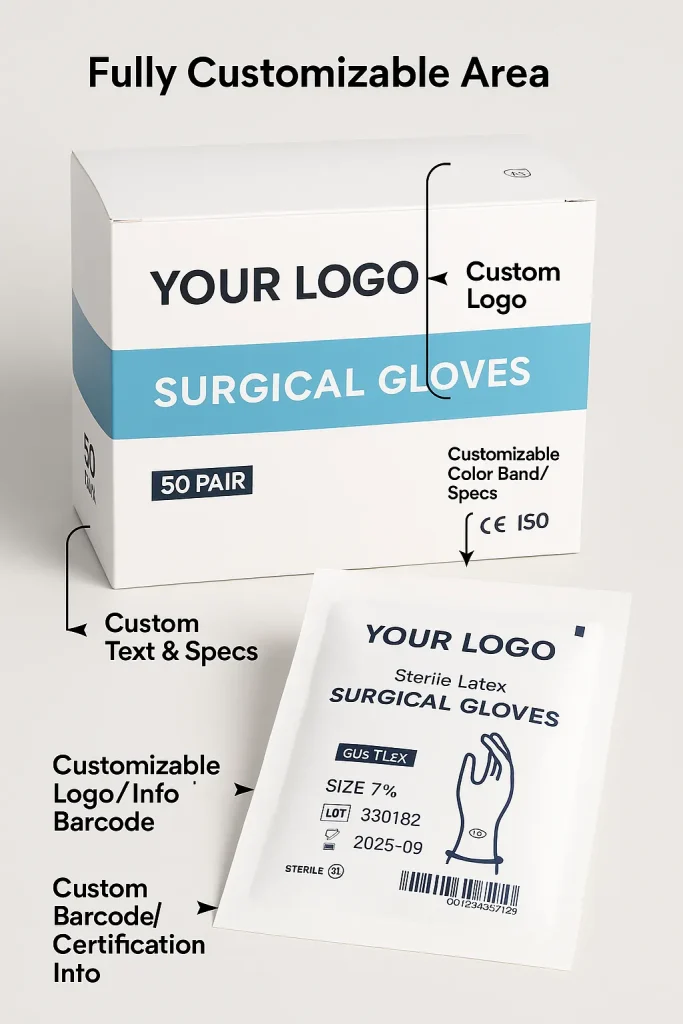

Packaging Design & Brand Customization

Surgical gloves can be supplied in custom-printed sterile inner pouches with multi-language instructions for use. Surgical disposable gloves are also supported with fully customized outer packaging, including box layout, color bands, SKU icons, and shipping carton identification.

FAQs About Surgical Gloves

From materials and specifications to sterilization, packaging, and regulatory compliance, our FAQ covers what buyers care most about when sourcing Surgical Gloves. We explain product options, including latex and nitrile types, thickness, texture, and cuff length, as well as quality assurance measures, sterility standards, and traceability. We also address customization possibilities, OEM and private labeling, production capacity, and delivery timelines to help buyers make informed decisions.

1. Why choose a surgical gloves factory instead of a trading company?

Buying directly from a factory gives buyers full visibility into materials, production control, and quality systems. As a manufacturer, we manage compounding, forming, sterilization, and packing in house with clear accountability. This reduces cost layers and improves response speed for buyers. Surgical gloves produced at the source offer better consistency, technical support, and long term supply stability worldwide.

2. Are your surgical gloves compliant with international regulations?

All products are made under certified quality systems that align with global medical regulations. Processes include validated sterilization, routine pinhole testing, and physical performance checks during production. Documentation for CE, ISO, and FDA is supported for different markets. Surgical gloves are manufactured to meet safety, traceability, and clinical use requirements consistently.

3. Do you manufacture both latex and nitrile surgical gloves?

Our factory manufactures both natural latex and synthetic nitrile options on separate production lines. Latex provides excellent elasticity and comfort, while nitrile supports latex free needs and chemical resistance. Specifications such as thickness and texture can be adjusted by material type as required. Surgical gloves are configured based on clinical preference and specific market demand.

4. Can you provide OEM and private label services for surgical gloves?

OEM and private label services are handled directly at the factory level efficiently. Buyers can customize pouch printing, box layout, language, and brand identity elements professionally. Our team supports artwork review and compliance checks before mass production begins. Surgical gloves maintain consistent quality while matching your branding strategy accurately and reliably.

5. How do you ensure batch-to-batch quality consistency?

Quality consistency is ensured through standardized raw materials, controlled production parameters, and defined inspection points. Each batch is tested for strength, integrity, and sterility performance before release. Records are retained for review and full traceability purposes. Surgical gloves from repeat orders meet the same performance expectations reliably and consistently.

6. What AQL and sterility levels do your surgical gloves meet?

Standard production supports medical grade pinhole acceptance levels with options for customization effectively. Sterile products are validated using EO or Gamma methods to achieve reliable sterility assurance levels. Sampling follows recognized testing standards across different markets. Surgical gloves are suitable for operating room and procedural use environments safely.

7. Can I order trial samples before placing a bulk order?

Sample packs are available for evaluation of fit, grip, and packaging quality easily. Buyers may request standard samples or agreed specifications for review beforehand. Pilot runs support internal testing and approval processes efficiently. Feedback can be applied before scaling production. Surgical gloves sampling helps reduce procurement risk significantly for buyers.

8. What is your typical production capacity for surgical gloves?

The glove factory operates automated dipping and sterilization lines designed for medical output consistently. Capacity supports a stable monthly supply and large volume programs efficiently worldwide. Production planning is handled internally to meet timelines accurately and professionally. Surgical glove orders are scheduled to balance speed and quality requirements effectively.

9. How do you handle traceability and product identification?

Each shipment includes the lot number, production date, and expiration marking clearly visible to buyers. Sterilization batches are linked to quality records for review purposes carefully and completely. Optional barcode or QR code systems are supported when required as needed. Surgical gloves traceability meets hospital and regulatory expectations fully and reliably for all customers.

10. How fast can you ship international bulk orders?

Lead time depends on order size, customization, and sterilization scheduling cycles carefully and efficiently managed. Standard items ship faster, while OEM orders require additional preparation time for documentation. Export documents are managed by our team professionally and accurately. Surgical gloves are shipped through stable global logistics partners efficiently worldwide for all shipments.

Contact Us