The development of protective clothing gives workers more defense against heat, fire, along chemicals. Nomex Coveralls are a recognized option for people who need safety and comfort at work. The garments are common in oilfields, factories, and in addition to firefighting units. The following content explains why industries depend on them, the advantages they bring, and the disadvantages you should know before choosing them.

What Are Nomex Coveralls?

Nomex is a heat- and flame-resistant aramid fiber developed by DuPont. Unlike treated cotton fabrics that rely on chemical finishes for fire protection, Nomex fibers are inherently flame resistant. This means their protective properties are built into the molecular structure and cannot be washed or worn out over time.

Nomex fibers react to extreme heat (up to 800–1000°C) by swelling and thickening, forming a carbonized barrier that slows heat transfer. This critical reaction provides workers with extra seconds to escape dangerous flashover conditions. Additionally, Nomex does not melt or drip, which prevents secondary burns caused by molten fabric.

Because of these properties, Nomex coveralls are widely used in industries where thermal hazards, chemical exposure, and electric arc risks are common.

Advantages of Nomex Coveralls: Fire Resistance, Durability, and Cost-Effectiveness

Nomex coveralls are widely valued for their reliable fire and heat protection. Unlike treated fabrics, Nomex has inherent flame resistance, meaning its protective qualities are built into the fiber and do not wash out. When exposed to extreme heat (up to 800–1000°C), Nomex fibers swell and thicken, creating a char barrier that slows heat transfer to the wearer. This reaction provides crucial extra seconds to escape dangerous situations like flashovers.

Nomex also maintains strength at high temperatures. For example, at 254°C (489°F), where many other fibers melt, Nomex retains about 50% of its original breaking strength. This durability helps reduce burn severity and serious injuries among firefighters, pilots, and industrial workers.

Resistance to Chemicals and Abrasion

Nomex fibers offer high resistance to many chemicals, making them superior to traditional cotton and polyester workwear in environments with chemical exposure. The aramid fiber structure also provides excellent abrasion resistance, giving Nomex coveralls a longer service life in tough work conditions. Certain Nomex blends, like Nomex MHP, protect not only from flames and heat but also from electric arcs and minor molten metal splashes.

Cost Savings Over Time

While Nomex coveralls are more expensive upfront compared to treated cotton or polyester suits, they provide long-term savings. Their fire-retardant qualities are permanent—no re-treatment is needed. Nomex coveralls can last up to five times longer than FR cotton under regular industrial laundering. This durability reduces replacement costs and improves overall value for industries requiring flame-resistant clothing.

Trusted Safety Standards and Global Acceptance

Nomex garments meet or exceed major safety standards, including NFPA 2112 and various ASTM and ISO certifications. Firefighter turnout gear made from Nomex consistently outperforms minimum strength requirements. Because of their proven reliability, Nomex coveralls are widely used in fire services, oil and gas, chemical, aviation, and electrical utility sectors worldwide.

Key Data and Usage Examples of Nomex Coveralls

- Provide critical escape time during flashover conditions at 800–1000°C.

- Maintain about 50% breaking strength at 254°C (489°F), unlike fibers that melt.

- Nomex MHP fabrics withstand continuous exposure to 204°C (400°F) for months.

- Last up to five times longer than FR cotton under industrial laundering.

- Trusted worldwide by emergency workers for performance in high-risk scenarios like cockpit fires and flashovers.

Disadvantages of Nomex Coveralls: Cost, Comfort, and Design Limitations

Dupont Nomex coveralls offer excellent fire protection, but they come with several drawbacks users should consider:

Higher Initial Purchase Cost

Nomex coveralls are generally 2 to 4 times more expensive than cotton-treated FR or polycotton blends. While the higher price may seem steep upfront, some argue that Nomex’s durability can reduce replacement frequency, potentially lowering long-term costs.

Heavier Weight and Comfort Issues

Nomex fabrics range from about 5 to 7 oz/yd², making these coveralls noticeably heavier than traditional cotton or synthetic options. The heavier weight adds to the wearer’s fatigue and can restrict movement during long shifts. Compared to alternatives like PBI flight suits, Nomex scores lower for comfort, especially in thermal insulation, causing extra heat buildup.

Limited Color and Design Options

Nomex coveralls usually come in standard colors such as navy blue, tan, or khaki. This limits customization for companies wanting branded uniforms or high-visibility designs. While reflective tapes and embroidery can be added, they increase cost and are less versatile than in other fabrics.

Reduced Breathability and Heat Build-Up

Nomex is less breathable than natural fibers like cotton. Its rigid polymer structure traps heat and moisture, which can lead to discomfort, sweating, and fatigue—particularly in hot climates. Some workers in tropical environments report heat exhaustion and skin irritation after prolonged use.

Additional Notes on Durability and Safety

Nomex doesn’t melt or drip when exposed to flames, but can char and develop holes in high-heat areas, even with thicker fabric (7 oz).

In tests, Nomex continued glowing for 9 seconds after jet fuel exposure versus 1 second for PBI, indicating more residual heat.

The fabric’s tensile strength (340 MPa) makes it durable but doesn’t improve comfort during heat stress.

Real-World Examples of Nomex Coveralls

Refinery workers have switched from Nomex to lighter cotton FR coveralls due to heat retention concerns, despite some compromise in fire protection.

Military aircrew flight suits in Nomex are limited to colors like tan and green because of chemical and dyeing restrictions.

Emergency responders in tropical zones sometimes face heat exhaustion while wearing Nomex coveralls, highlighting their breathability limits.

Key Industry Applications of Nomex Coveralls

Nomex Dupont coveralls are essential safety gear across many high-risk industries. Their flame resistance, durability, and heat protection make them ideal for hazardous work environments. Here’s a closer look at how Nomex coveralls are used in different sectors and what advantages they offer.

Nomex Coveralls in Oil and Gas Industry

In oil and gas, workers face extreme heat, flames, and flash fire risks. Nomex coveralls excel here by providing:

Certified protection meeting ASTM F1506, NFPA 2112, ISO 11612, and other key safety standards.

Fabric weights of 4.5 oz/yd² (153 g/m²) or 6 oz/yd² (203 g/m²) with blends of Nomex, Kevlar, and antistatic fibers.

Features like breathable, pre-shrunk fabric, 5 cm reflective tape for visibility, and reinforced stitching for durability.

Use throughout the oil and gas chain—from exploration to refining.

Safety validation through Thermo-Man® and Arc-Man® tests, ensuring flame and arc flash resistance.

Nomex Coveralls in Firefighting and Emergency Services

Firefighters rely on Nomex FR coveralls for protection against intense heat and flames. These Nomex coveralls:

They are part of layered turnout gear, often combined with moisture and thermal liners such as EPTFE-coated Nomex/Kevlar.

Use fabrics weighing 195 gsm (outer layers) and 105 gsm (moisture barriers).

Include reflective tape on arms and legs for high visibility.

Comply with NFPA 2112 and EN standards.

Resist breaking open under heat while maintaining breathability for comfort.

Nomex Coveralls for Electrical and Utility Workers

Insulated Nomex coveralls offer critical arc flash and electrical hazard protection for electricians, linemen, and utility workers by:

Providing inherent insulating and flame-resistant properties that last through repeated use.

Meeting high arc flash protection levels (CAT 2 or higher).

Featuring lightweight designs for prolonged wear and arc-resistant closures.

Enhancing safety with added visibility features.

Nomex Coveralls in Military and Aviation

In military and aviation settings, Nomex is valued for:

Lightweight, flexible protection against burns from fires, explosions, and electrical faults.

Standard issue for pilots, crew, and support staff.

Designs that allow full mobility with multiple secure pockets.

Colors include navy blue, tan, and olive to suit operational needs.

Compliance with stringent military and aviation safety certifications.

Industry Impact and Options of Nomex Coveralls

- Widely used in oilfields, mining, power, manufacturing, chemical plants, firefighting, and military bases.

- Proven to reduce burn injuries significantly in realistic tests (Thermo-Man®).

- Available in sizes S to 4XL and many colors like blue, orange, white, and grey.

- Offered in one-piece suits or multi-layer setups, often with added reflective elements for high visibility.

Nomex Coveralls vs. Other Flame-Resistant Fabrics: Key Differences and Comparisons

Nomex coveralls are made from inherently flame-resistant aramid fibers. This means they provide exceptional heat and flame protection up to 700°F (371°C) without melting or dripping. Nomex keeps its protective qualities even after many washes, making it durable and reliable. This durability gives Nomex coveralls a typical lifespan of 3 to 5 years, which is longer than many other flame-resistant fabrics.

Treated Cotton FR Coveralls

Treated cotton FR coveralls use cotton fabric chemically treated to resist flames. They are generally more affordable and breathable, which makes them comfortable in hot environments. However, the flame resistance can lessen over time, especially if not cared for properly. Their lifespan under heavy use is about 1 to 2 years.

Compared to Nomex, treated cotton:

– Offers a lower level of flame protection

– Is heavier and less durable

– Costs less upfront (e.g., around $82–$123 on average)

This makes treated cotton coveralls suitable for low-risk situations or short-term use where budget is a priority.

Nomex vs. Polyester and Blended Fabrics

Standard polyester fabric is not flame-resistant and can melt in high heat, creating extra danger. Blended fabrics that mix Nomex with other fibers (such as Kevlar or modacrylic) offer varied levels of protection and comfort. These blends are inherently flame resistant and last for the garment’s lifetime, but typically fall between pure Nomex and treated cotton in price and performance.

Performance Summary

| Feature | Nomex | Treated Cotton | Polyester/Blends |

|---|---|---|---|

| Flame Resistance | High (up to 700°F / 371°C) | Moderate, decreases over time | Low (not inherently FR) |

| Lifespan | 3–5 years | 1–2 years | Varies, shorter for treated fabrics |

| Comfort & Breathability | Moderate | High | Low for polyester |

| Cost | Highest | Lower | Varies, generally low for polyester |

Who Should Choose Which?

- Nomex coveralls

are ideal for workers exposed to high heat or flame hazards, such as firefighters, electricians, and industrial workers. The higher initial investment pays off with longer protection and durability. - Treated cotton FR coveralls

fit better for occasional use or projects where cost is a concern, and risks are lower. - Polyester fabrics

should generally be avoided where flame resistance is critical due to safety concerns.

Choosing the right fabric depends on your specific safety needs, budget, and work environment.

Choosing the Right Nomex Coveralls: Key Factors and Fit Guide

Selecting the right Nomex coveralls depends on several important factors to ensure safety, comfort, and proper protection on the job.

Key Factors to Choose the Right Nomex Coverall

Job Role:

Different industries like oil and gas, firefighting, electrical utilities, aviation, and chemical processing require flame-resistant (FR) clothing. Nomex coveralls protect against fire, electric arcs, and chemical splashes.

Risk Level:

Higher risk environments need thicker or multi-layer Nomex fabrics for better heat and flame protection.

Comfort:

Look for coveralls that balance protection with breathability and ease of movement. For example, a 4.5 oz. Nomex IIIA coverall is lightweight but still protective for long shifts.

Sizing, Fit, and Layering Nomex Coverall

General Fit:

Nomex coveralls are usually worn loose for comfort and to fit over other clothing layers.

Sizing Tips:

If you’re between sizes of Nomex coveralls , it’s best to size up for a better fit.

Example Sizes:

- For someone 6’2″ tall and weighing 160-250 lbs, XL or 2XL usually fits well.

- Chest sizes range from 30–32 inches (XS) up to 66–68 inches (6X).

Fit Chart Overview:

| Coverall Size | Chest (inches) | Waist (inches) |

|---|---|---|

| X-Small | 36–38 | 30–32 |

| Medium | 44–46 | 38–40 |

| 2X | 56–58 | 50–52 |

| 4X | 64–66 | 56–58 |

Layering:

Nomex Coveralls are designed to allow wearing thermal liners or extra clothing underneath. Sizes and lengths vary (short, regular, long) to fit different body types and job needs, important in aviation and emergency roles.

Care and Maintenance Tips for Nomex Coveralls

Proper upkeep is crucial to maintain fire resistance and durability:

– Wash with mild detergents only; avoid chlorine bleach and fabric softeners.

– Wash separately to avoid contamination by flammable substances.

– Inspect regularly for wear or damage, as compromised fabric reduces protection.

– Monitor fit after washing, as shrinkage can occur.

– Always follow the manufacturer’s care instructions.

Useful Examples

Workers in petrochemical plants often choose 4.5 oz. Nomex IIIA coveralls with reinforced stitching and a roomy fit for everyday use.

Military and aviation suits like the CWU-27/P are made from Nomex, meeting strict standards for flame protection and offering multiple size and length options.

Nomex fibers do not melt or burn, maintaining protection even after many washes.

Leading Brands and Manufacturers of Nomex Coveralls

Several top coverall manufacturers lead the Nomex coverall market, providing trusted safety and quality:

DuPont: Inventor of Nomex fibers; their coveralls are the industry standard for flame and heat protection worldwide.

Lakeland Industries: American company specializing in Nomex and flame-resistant garments, widely used in oil & gas, chemical, and healthcare sectors.

Honeywell: Offers high-performance Nomex coveralls for aerospace, pharmaceuticals, and energy industries.

Ansell: Focuses on flame-resistant and chemical-protective coveralls for high-risk environments.

Other notable brands include Bulwark, Workrite Uniform Company, VF Corporation, and Crown Safety, often serving specialized or regional markets.

Where to Buy Nomex Coveralls in Bulk?

Bulk purchases are common for companies needing reliable protective clothing. Consider these buying options:

Purchase directly from manufacturers like DuPont and Lakeland for guaranteed authenticity and certification.

Use online industrial supply platforms (e.g., DirectIndustry) to compare prices and features from multiple brands.

Regional distributors such as Crown Safety and VF Corporation assist with local bulk procurement in markets like Africa.

Always request certification documents (e.g., NFPA 2112, ISO 11612) to confirm safety compliance.

FAQs for Nomex Coveralls

1. Are Nomex coveralls worth the price?

Yes. Although more expensive upfront than treated cotton or polyester blends, Nomex coveralls offer long-term value. Their inherent flame-resistant properties do not wash out, reducing replacements. Compliance with NFPA 2112, ASTM, and ISO 11612 ensures workers remain protected in high-risk environments. For industries like oil and gas, firefighting, aviation, and utilities, investing in Nomex can prevent costly safety incidents and regulatory penalties.

2. How long do Nomex coveralls last?

Typically 3–5 years, depending on usage and laundering, compared to 1–2 years for FR cotton. Certain blends, like Nomex MHP, withstand continuous heat or minor molten metal splashes. Proper care—mild detergent, avoiding bleach, and regular inspections—further extends lifespan.

3. Are Nomex coveralls comfortable in hot weather?

Nomex is heavier and less breathable than cotton, but lighter options (e.g., 4.5 oz Nomex IIIA) balance comfort and protection. Pre-shrunk fabrics, ergonomic seams, and proper layering help reduce fatigue and overheating, even in warm climates.

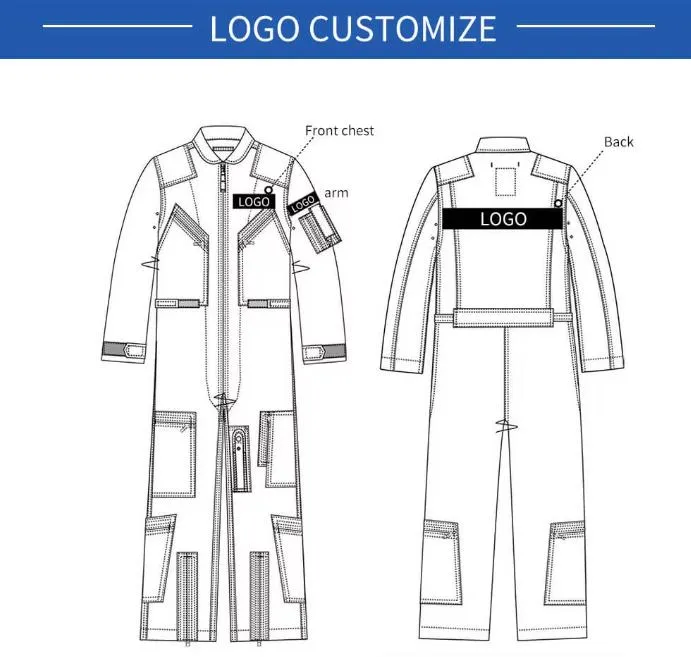

4. Can Nomex coveralls be customized?

Yes. Nomex coveralls options include:

- Logos

via embroidery, screen printing, or heat-sealed patches - Reflective stripes

for visibility - Color and sizing

choices, including gender-specific fits - Functional features

like extra pockets, reinforced knees/elbows - Bulk discounts

for 50–100+ units

Customization ensures safety, branding, and operational efficiency.

Conclusion

Nomex coveralls continue to be a trusted choice for companies that place worker safety first. They may cost more upfront, but the long life, strong protection, and global certifications make them a solid investment. Whether your team works in oilfields, firefighting, aviation, or utilities, Nomex offers proven defense where it matters most. For bulk supply or tailored options, reach out to a trusted coverall distributor today.