When every dollar counts, Intco Isolation Gowns seem like an attractive choice. They’re widely available and cost-effective, but does lower price mean lower protection? Some teams praise them for low-risk use, others note tearing and liquid issues. Before stocking up, let’s examine Intco isolation gowns‘strengths, weaknesses, and whether a slightly pricier gown could save you money (and safety risks) long-term.

A Guide to Intco Isolation Gowns and Their Features

From my experience, Intco makes its disposable isolation gowns from a few different protective materials. This lets them meet the specific fluid protection needs found in healthcare settings. Let’s look at the key materials.

SPP+PE Laminate Disposable Gown (Model INIG-45W/INIG-45)

- Material: This isolation gown is made from spunbonded polypropylene with a plastic laminate. The 45g fabric is thicker, which helps stop fluids from getting through.

- AAMI Protection: I have seen this gown marketed for up to AAMI Level 3 protection. This is based on tests like AATCC 42 for impact and AATCC 127 for water pressure. I must stress, you should not use this for surgery or any task requiring Level 4 protection. It’s also not for areas with high heat or flammable gases.

- Design Details: I find the design very practical. It is knee-length with a round neck. It includes strong ties for the neck and waist, along with elastic wrist cuffs and long sleeves. Please note, it is non-sterile and you should only use it once. It comes in a Large size and is White.

- Packaging: You’ll find these sold in packs of 10 isolation gowns. Some sellers might have other bulk or case sizes. I suggest you always check the pack size before you buy.

- Positioning: I recommend this gown for situations that need a good fluid barrier. However, it is not for surgical use or the highest-risk environments.

CPE Isolation Gowns

- Material: These isolation gowns are made completely from a cast polyethylene (CPE) plastic film. They are available in blue, white, or yellow. A key benefit is that they do not contain natural rubber latex.

- Key Features: It has a simple pullover neckline, a strap tie at the waist, and a choice of soft or elastic cuffs. I think the option for a fine or coarse surface texture is a great touch for better grip.

- Performance: This gown is excellent for blocking water and preventing stains. Its main purpose is to create a strong liquid barrier, so it is not very breathable. You can find them in weights from 30–80g with a standard size of 120×190 cm. Custom sizing is also an option if you need it.

- Packaging: Each isolation gown comes packed in its own bag. A standard case includes 15 bags per box and 10 boxes per carton, but you can ask about custom options.

- Intended Use: I suggest using these for high-risk liquid exposure. The plastic build gives you strong fluid resistance, but comfort is secondary. Breathability is not as good as fabric gowns.

SMMS/SMMS Fabric – Yellow Gowns (Level 2)

- Material: This gown uses a 25gsm SMMS nonwoven fabric. In my opinion, this weight provides a good balance between protection and comfort.

- AAMI Rating: It is certified for AAMI Level 2, and distributors have verified its CE certification. This makes it a solid choice for work with low to moderate fluid exposure.

- Design/Color: It is often supplied in yellow. I find this color helps staff quickly see that it’s a Level 2 gown.

- Use Case: I recommend this gown for longer wear when comfort is important. The SMMS fabric is more breathable than laminated or plastic-coated gowns. This makes it a popular choice for staff on long shifts or who need to move around a lot.

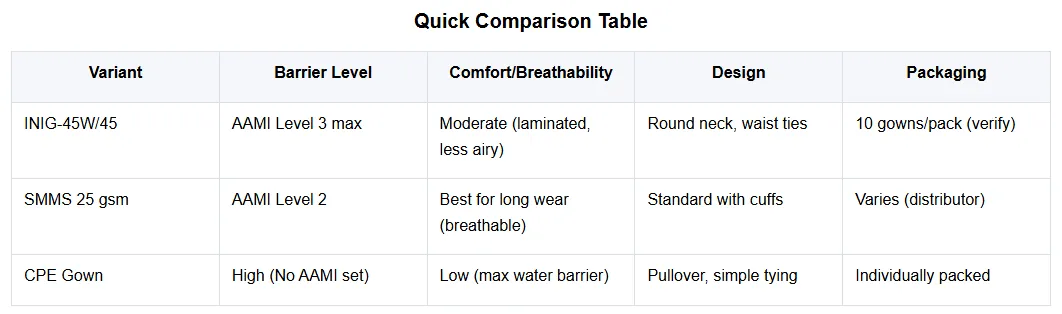

Summary: So what is my final take? If you need a lightweight gown for simple, low-exposure care, I suggest the PP+PE gown. For jobs that require a strong barrier against fluids, I recommend the CPE gown. I believe Intco does a good job of meeting real-world needs for protection, comfort, and fast delivery. My advice is to always confirm the size, color, protection rating, and packaging. This will ensure you get the right isolation gown for your staff’s workflow.

Intco Isolation Gowns’ Pros and Cons Breakdown

We tested Intco’s isolation gowns to separate fact from hype. Here are the proven strengths and surprising limitations you should know before buying.

Pros of Intco Isolation Gowns

Intco isolation gowns earn steady use in clinics and hospitals for two plain reasons – the quality stays the same roll after roll, plus the price stays low. The line covers AAMI Levels 1, 2 along with 3, so staff match the gown to the task, from quick vitals checks to tasks that splash fluid.

The fabric choices – spunbond polypropylene fused to a PE film, or SMS/SMMS layers – block liquids and microbes. Explore our SMS Isolation Gown for breathable options. The SPP+PE model keeps surface moisture from reaching clothes cutting the odds of cross transfer. Elastic at the wrists, ties at neck but also waist, and a cut that ends just below the knee seal gaps without trapping heat.

SMS/SMMS versions weigh little as well as let air pass, so heat leaves and cool air enters. Staff finish long shifts with less sweat plus less pull on the shoulders. Price lists place Intco below most rivals for each AAMI grade, yet the gowns still pass ASTM but also EN tests. A tight budget no longer forces a clinic to pick between protection and solvency.

Cons of Intco Isolation Gowns

Despite their many strengths, Intco isolation gowns also have some limitations. Some users report that some gowns, particularly the lighter Level 1 variants, can tear more easily under stress or during fast-paced tasks. This vulnerability could potentially compromise protection if the gown gets damaged before or during use.Another common concern is related to the liquid resistance of some gowns.

While the SPP+PE laminate offers good fluid repellency, it tends to be less breathable and can feel stiff, which might influence comfort for long periods. Conversely, the SMS/SMMS gowns are more breathable but may not provide the same level of liquid barrier protection, making them less ideal in high splash-risk scenarios.

Sizing can also be an issue. Some users find that the gowns run a bit large or small, which can affect fit and, consequently, the protective seal around the wrists and neck. Poor fit might increase the risk of exposure to contaminants.

Lastly, while Intco’s gowns meet basic regulatory standards, they are not designed for surgical gowns or high-risk pathogen environments (Level 4 protection). For settings requiring maximum barrier protection, healthcare providers will need to look for specialized gowns beyond Intco’s current offerings.

Replacement Brands for Intco Isolation Gowns

For healthcare providers seeking alternatives offering improved performance or additional features, several brands stand out. Morntirp is a leading option known for:

Wide Protection Range: Crafting gowns that fulfill every AAMI protection level from 1 through 4.

Premium Materials: Using SMS and SMMS fabric blends to maximize comfort and fluid resistance.

Eco-Friendly Production: Innovating with biodegradable gowns using PHA and PLA to address environmental concerns.

Industry Certifications: Carrying EN13795, ISO 13485, and CE certifications attesting to quality and safety standards.

Reliable Manufacturing: Ensuring consistent high quality with sizable production capabilities.

Other reputable disposable isolation gown brands include DuPont, 3M, Medline Industries, Owens & Minor (HALYARD), Mölnlycke Health Care, Medicom Group, and Winner Medical. These manufacturers are recognized for advanced protective features, durability, and compliance with healthcare regulations.

- DuPont is known for its Tyvek® and Tychem® gowns, offering excellent barrier protection against liquids, particles, and chemical splashes. These gowns are often used in high-risk healthcare and laboratory settings.

- 3M produces a range of disposable gowns designed for comfort and breathability while maintaining high fluid resistance, suitable for surgical and isolation purposes.

- Medline Industries offers various gown types, including reinforced and reusable options, emphasizing fit, comfort, and cost-effectiveness for hospitals and clinics.

Critical Considerations for Isolation Gown Selection

Matching AAMI Levels to Clinical Tasks

AAMI Level 1: I recommend Level 1 for minimal r isk situations, like basic patient care or for visitors. You should choose this level if your team has almost no contact with fluids. The label, package, or product page must state “AAMI Level 1.”

AAMI Level 2: You need Level 2 for low-risk tasks like blood draws, suturing, or work in pathology labs gowns. The label must show “Level 2.” I suggest you match it to jobs with a small chance of fluid spray.

AAMI Level 3: In my opinion, for moderate-risk settings like the ER or arterial blood draws, you must use a Level 3 gown. I insist on seeing proof that it passed the AATCC 42 (≤1.0g) and AATCC 127 (≥50 cm) barrier tests, which you can find on the spec sheet.

AAMI Level 4: For high-risk areas like surgery where there’s heavy fluid exposure, you need Level 4. I require seeing the ASTM F1671 viral barrier data, and the gown must show it passed this test in all its zones.

Validating Gown Design and Features

I always check the elastic cuffs to make sure they create a good seal with gloves. I also measure the sleeve length and test its stretch. Neck and waist ties: Look at the ties. They need to be adjustable for a proper fit. I find that pullover gowns are quick to put on, but taking them off safely can be tricky. You need to decide on back coverage (open-back vs full-back). Does it fit your team’s workflow and splash risk? For situations with a high risk of exposure, I recommend using full-back gowns that have passed PB70 testing.

Ensuring Size, Color, and Identification

I suggest you make sure a full size range (M–2XL or more) is available. Ask the supplier for a size chart that includes measurement guidance. Let’s talk about color coding. Many Intco gowns come in white. If your policy uses color to show protection levels (e.g., blue isolation gowns/yellow isolation gowns), I recommend asking the distributor if other options are available. I make it a rule to check the labels on cartons and pouches. They must state the AAMI level, size, and intended use.

Sterility and Packaging

Most Intco isolation gowns I’ve seen are non-sterile. If you need gowns for surgery, I recommend confirming they come in sterile EO-packaging. You should also ask for the related EO residual data. I always confirm the packaging details. Check for 10-packs or individual poly-wraps (good for CPE). I also make sure each pouch has a traceable lot number.

FAQs

- Are Intco Isolation Gowns FDA-approved?

Yes, Intco Isolation Gowns are FDA-registered as Class I medical devices and meet basic protective standards for healthcare use. However, they are not rated for high-risk surgical procedures.

- What’s the typical lead time for bulk Intco gown orders?

Standard orders usually ship within 2-3 weeks, but lead times may extend during high-demand periods. For urgent needs, ask about expedited shipping options. - Can Intco gowns be reused or sterilized?

No, these are strictly single-use disposable gowns. Attempting to sterilize and reuse them may compromise their protective barrier.

- How do Intco gowns compare to 3M or Kimberly-Clark gowns?

While more affordable, Intco gowns generally offer less durability and fluid protection than premium brands. They’re suitable for low-to-medium risk situations but may not be ideal for high-exposure environments.

Conclusion

Intco Isolation Gowns offer an affordable PPE solution, making them a practical choice for low-risk settings. However, concerns about durability and liquid resistance may limit their effectiveness in high-exposure environments. While they work well for basic protection, facilities needing reinforced safety might prefer higher-grade alternatives. Need customized isolation gowns with better protection? We provide tailored PPE solutions to match your exact requirements—contact us today for competitive pricing and bulk order options. Stay safe without compromising quality!