Frequently Asked Questions About FFP1, FFP2 and FFP3 Dust Masks

Clear guide on FFP1, FFP2, and FFP3 dust masks, including their filtration efficiency, inward leakage limits, and compliance with EN 149:2001+A1:2009 certification standards. This FAQ page provides detailed answers to common questions about how to choose the right FFP mask, differences between FFP1, FFP2, and FFP3, proper usage and fit, mask duration, valved vs. non-valved options, and recommendations for industrial, construction, healthcare, and public environments. To help you make the right choice.

FP1 / FFP2 / FFP3 Dust Mask FAQ

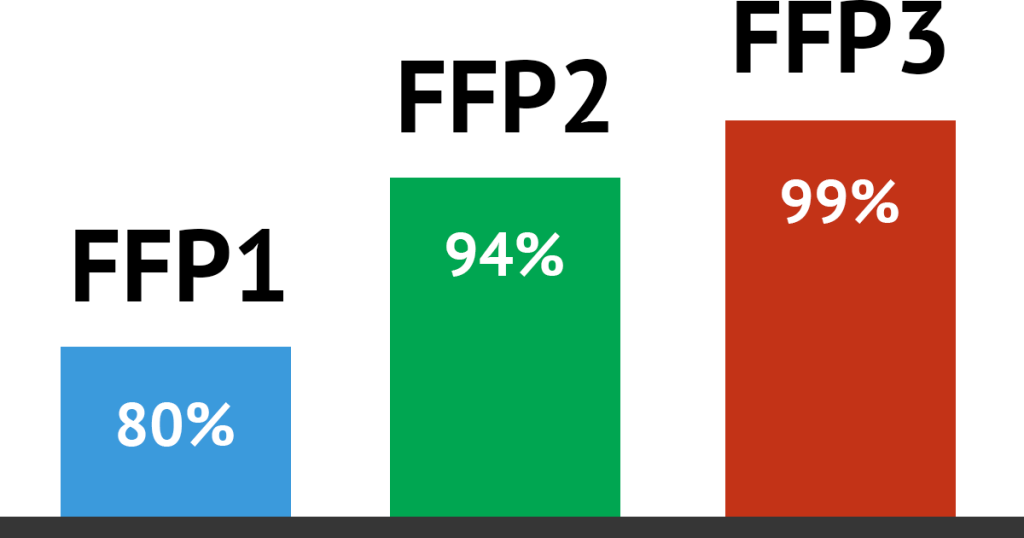

What filtration performance distinguishes FFP1, FFP2, and FFP3 dust mask?

FFP1, FFP2, and FFP3 dust masks are classified according to the EN 149:2001+A1:2009 standard, which evaluates filtration efficiency, inward leakage, breathing resistance, and overall performance under conditions such as high humidity and particle loading. This ensures each mask category meets consistent protection requirements.

FFP1 masks provide 80% filtration efficiency and are intended for low-to-moderate exposure to non-toxic dust. They are commonly used for light sanding, cleaning work, or home DIY tasks where airborne risks are relatively low.

FFP2 masks offer 94% filtration efficiency, giving reliable protection against fine particles like construction dust, mold spores, and certain aerosols. They are suitable for workplaces where air quality may be affected by moderate levels of particulates.

FFP3 masks deliver 99% filtration efficiency and have the strictest limits on inward leakage, offering the highest level of protection. They are used in environments with hazardous fine particulates, such as asbestos, silica dust, chromium VI, welding fumes and certain biological contaminants.

In general, a higher FFP class means stronger filtration, lower leakage, and more stringent testing, resulting in a higher level of respiratory protection.

Is an FFP2 dust mask more reliable than KN95 for workplace protection?

Although FFP2 and KN95 respirators look similar, the standards behind them involve different testing requirements and performance expectations.

FFP2 masks must pass the European EN 149 standard, which includes strict assessments for particle penetration, total inward leakage, breathing resistance, filter clogging and performance against both water-based and oil-based aerosols. This ensures the mask performs reliably even in demanding industrial conditions.

KN95 masks are produced under the Chinese GB2626 standard. While they also test filtration efficiency, the standard does not require the same level of inward leakage testing and does not include the same oil aerosol resistance requirements found in EN 149. As a result, real-world fit and protection levels can vary more from model to model.

For industrial workplaces—such as construction sites, mining operations, woodworking shops, and manufacturing facilities—FFP2 respirators generally offer more consistent and independently verified protection, especially when CE-certified by an accredited Notified Body.

Are FFP2 dust mask still recommended for virus protection in 2025?

Yes. FFP2 masks continue to be recommended for preventing airborne infectious diseases in 2025, especially in situations where close contact, poor ventilation or high-density indoor environments increase transmission risk.

FFP2 respirators provide 94% filtration efficiency, a tight facial seal that limits aerosol leakage around the edges, and performance requirements aligned with medical and occupational health guidelines. These features make them more effective than loose-fitting face coverings when dealing with fine infectious aerosols.

Because of their reliable protection, FFP2 masks remain widely used in hospitals, clinics, long-term care facilities, airports, public transportation, and busy indoor spaces—anywhere higher levels of respiratory protection are needed.

In short, FFP2 respirators continue to be a trusted and recommended option for virus protection in 2025.

When should you choose an FFP3 dust mask instead of an FFP2 one?

FFP3 respirators are recommended in situations where the air contains highly hazardous, carcinogenic, or ultra-fine particulates that pose a serious health risk and demand the highest level of filtering efficiency.

Common scenarios include:

Asbestos removal, where microscopic fibers can cause severe long-term lung disease.

Cutting or grinding materials containing silica dust, which produces very fine respirable particles.

Welding operations, especially those generating fumes with metal oxides or chromium VI.

Chemical processing areas, where toxic aerosols or reactive particles may be present.

Handling pharmaceutical powders, particularly in production or compounding rooms.

Advanced infection-control procedures, where exposure to high viral loads or aerosol-generating tasks requires maximum respiratory protection.

With 99% filtration efficiency and the lowest allowable inward leakage, FFP3 masks provide a substantial safety margin for workers facing airborne carcinogens or environments with heavy particulate concentration, making them the preferred choice in high-risk industrial or medical settings.

How many times can an FFP2 dust mask be worn before it loses performance?

Most FFP2 masks are classified as single-use (NR), meaning they are designed for one work shift—typically around 8 hours of continuous or intermittent use under normal conditions. Their filtering performance relies heavily on electrostatic charge within the filter media, which can degrade with moisture, heat and particle buildup.

Factors such as high humidity, heavy breathing during physical work, perspiration, or exposure to dust and aerosols can accelerate performance decline. In these cases, the mask should be replaced sooner. You should change the mask immediately if it:

becomes damp or saturated

shows visible dirt or contamination

causes increased breathing resistance

fails a seal check or no longer fits tightly

has damaged straps, foam, or nose clip

Limited extended use may be acceptable in clean, low-aerosol indoor environments, but only if the mask remains dry, intact and maintains a reliable seal. When in doubt, replacing the mask is the safer option to maintain proper protection.

Can FFP3 and FFP2 dust masks be reused after disinfecting?

FFP respirators use electrostatic filter media, which trap fine particles through both mechanical and electrostatic mechanisms. This material is sensitive to heat, alcohol, steam, and UV exposure, all of which can weaken the fibers, strip the electrostatic charge, or deform the mask’s structure. Because of this, most disinfection methods can significantly reduce protective performance.

Masks marked NR (non-reusable) are intended for single-use only and cannot be safely cleaned or disinfected for another shift. Their design and materials are not tested for repeated exposure to moisture, wear, or cleaning agents.

Only masks marked R (reusable) are approved for multiple uses. These models must pass additional clogging and loading tests under the EN 149 standard to confirm they maintain filtration efficiency, breathing resistance, and structural integrity across more than one wear cycle.

For typical disposable FFP2 and FFP3 masks, attempting to disinfect them is not recommended, as it can degrade both filtration efficiency and the fit, reducing their ability to provide reliable respiratory protection.

How can you identify a genuine CE-certified FFP2 or FFP3 Dust Mask?

A genuine, legally compliant FFP2 or FFP3 respirator must display specific markings that confirm it has passed the full EN 149 certification process. The mask itself—not just the packaging—should clearly include:

CE mark followed by a 4-digit Notified Body number, indicating which accredited testing authority approved the product.

EN 149:2001+A1:2009 standard reference, confirming full compliance with European filtration, leakage and performance requirements.

Manufacturer name, brand or registered logo, ensuring traceability.

Mask classification, such as FFP2 NR, FFP3 NR, or FFP3 R.

Model number, batch/lot code or similar identification for quality control.

Instructions for use (IFU), including fitting guidance, limitations and warnings.

Counterfeit or non-compliant masks may carry incorrect markings, use fake CE labels, or lack traceable manufacturer information. To verify authenticity, always cross-check the 4-digit Notified Body number on the EU’s official NANDO database, which lists all accredited certification bodies authorized to certify PPE.

Are FFP2/FFP3 dust mask with exhalation valves suitable for public environments?

FFP2 and FFP3 masks with exhalation valves provide strong protection for the wearer, as the valve only opens during exhalation to reduce heat and moisture buildup. However, the air released through the valve is not filtered, allowing unfiltered breath, droplets and aerosols to escape.

Because of this, valved FFP masks are generally considered:

Suitable for industrial environments, where the goal is to protect workers from dust, fumes or hazardous particulates.

Unsuitable for public health or surgical settings, where preventing outward transmission is essential.

Restricted or prohibited in certain hospitals, public transport systems, laboratories and cleanroom environments due to insufficient source control.

Although the valve improves comfort during heavy work, it compromises protection for others. For shared indoor spaces or situations requiring both inward and outward filtration, non-valved FFP2/FFP3 masks are the preferred and recommended choice.

Do FFP2 or FFP3 dust mask fog up glasses, and how can this be prevented?

Fogging happens when warm, moist exhaled air escapes through gaps around the nose and rises to contact eyeglass lenses. While common, it can be minimized with proper fitting and additional precautions.

Effective measures include:

Firmly molding the nose clip to the bridge of the nose for a tight seal.

Choosing masks with high-density or contoured nose foam, which reduces air leakage.

Adjusting the top strap tension to hold the mask snugly against the face without causing discomfort.

Applying medical or micropore tape along the upper edge of the mask to seal any remaining gaps.

Using anti-fog wipes, sprays, or a thin soap film on eyeglass lenses to prevent condensation.

A well-fitted mask not only reduces fogging but also improves filtration efficiency by minimizing inward and outward leakage, ensuring both comfort and effective protection during use.

Do beards interfere with the proper sealing of FFP2/FFP3 dust mask?

Yes. Facial hair interferes with the tight seal between the mask and the skin, which is essential for effective respiratory protection. Even short stubble or light beard growth can create small gaps, allowing contaminated air to bypass the filter and reducing overall protection.

Occupational health and safety guidelines recommend:

Maintaining clean-shaven skin along the areas where the mask edges contact the face.

Avoiding beard styles that extend under the mask edges or cover the sealing surfaces.

Considering alternative respiratory solutions, such as powered air-purifying respirators (PAPRs) with hoods, for workers who cannot shave due to personal or religious reasons.

Ensuring a proper seal is critical for both protection against hazardous dust, aerosols, and infectious particles and for maintaining the full effectiveness of FFP2 or FFP3 respirators in workplace or healthcare settings.

What does the CE mark with four digits mean on an FFP mask?

The CE mark on an FFP mask indicates that the product complies with the European Union Personal Protective Equipment (PPE) Regulation (EU) 2016/425. It confirms that the mask has been manufactured and tested according to strict safety and performance standards, ensuring reliable respiratory protection.

The four-digit number next to the CE mark identifies the Notified Body—an independent, accredited organization responsible for assessing the mask. This body oversees several critical aspects of quality and performance, including:

Testing filtration efficiency to confirm the mask effectively blocks particles.

Verifying total inward leakage, ensuring the mask forms a proper seal on the wearer’s face.

Auditing the manufacturer’s production processes, to confirm consistent quality control.

Ensuring batch-to-batch consistency, so each mask meets the same high standards.

Together, the CE mark and four-digit Notified Body code guarantee that the respirator meets the EN 149:2001+A1:2009 requirements for FFP2 or FFP3 performance, giving users confidence in its safety and effectiveness.

Are FFP1 dust masks still relevant in modern workplaces?

Yes. Although FFP1 masks provide the lowest filtration efficiency (around 80%), they remain relevant for low-risk environments where exposure is limited to non-toxic dust or large particles. Their lighter design and lower breathing resistance make them comfortable for extended wear during less demanding tasks.

Typical uses include:

Woodworking with soft or untreated materials, where dust is not hazardous.

Insulation installation, particularly with materials that do not produce harmful fibers.

Cleaning or sweeping tasks in offices, warehouses, or workshops.

Simple DIY projects at home or in low-exposure areas.

Handling non-hazardous construction debris, such as plaster or drywall dust.

However, in workplaces where fine, toxic, or carcinogenic particulates may be present, higher-grade masks such as FFP2 or FFP3 are strongly recommended to ensure adequate respiratory protection.

Are FFP3 Dust Mask suitable for healthcare, or only for industrial use?

FFP3 respirators are used in both industrial and healthcare settings, thanks to their high filtration efficiency and low inward leakage. Their 99% filtration performance under the EN 149 standard makes them the highest-performing disposable FFP respirators available.

In healthcare environments, FFP3 masks are recommended for:

Aerosol-generating procedures, such as intubation or bronchoscopy.

Handling patients with highly infectious or airborne pathogens, where maximum protection is required.

Specialized isolation units, including negative-pressure rooms or high-risk infectious disease wards.

In industrial settings, FFP3 masks protect workers from:

Hazardous dusts, including silica or asbestos fibers.

Welding fumes and metal oxides.

Toxic chemicals and fine bioaerosols.

Their combination of high filtration efficiency, tight seal, and certified performance makes FFP3 respirators a versatile choice for situations demanding maximum respiratory protection, whether in healthcare or industrial use.

Can children safely wear FFP2 dust mask, and are certified kids’ sizes available?

Standard FFP masks are designed and tested on adult faces, which means they may not fit children properly. A poor fit can create gaps that allow unfiltered air to bypass the mask, dramatically reducing its protective efficiency.

To address this, some manufacturers produce smaller FFP2 masks specifically sized for children, taking into account their facial dimensions. These masks are tested and certified according to the EN 149 standard, ensuring that they provide comparable filtration and inward leakage protection as adult FFP2 respirators—but only if a proper seal is achieved.

For children, achieving a snug fit is essential. Parents or caregivers should check that the mask:

Covers both the nose and chin fully

Forms a seal along the cheeks and bridge of the nose

Has adjustable straps or flexible nose clips for proper fitting

Without a secure seal, even a certified children’s FFP2 mask may offer limited protection. Therefore, selecting a certified kids’ size and carefully checking the fit are crucial for safe use.

How do you properly wear and adjust an FFP2/FFP3 dust mask for a secure seal?

Ensuring a secure seal is critical for the mask to provide its full protective performance. Proper wearing and adjustment include the following steps:

Position the mask correctly over the face so that it fully covers both the nose and chin. The mask should sit comfortably but snugly without gaps along the edges.

Place the headbands properly, pulling one strap over the crown of the head and the other over the base of the skull. This ensures even tension and keeps the mask firmly in place.

Mold the nose clip around the bridge of the nose by gently pressing along its length. A tight seal around the nose is essential to prevent warm, moist exhaled air from escaping.

Perform a seal check: inhale and exhale sharply while feeling around the mask edges for air leaks. Any noticeable leakage indicates that the mask needs adjustment.

A properly fitted FFP2 or FFP3 respirator maximizes filtration efficiency, reduces inward leakage, and enhances comfort during extended use. Regularly checking the fit, especially after adjusting straps or putting on glasses, helps maintain optimal protection.

Where can you buy authentic, CE-certified FFP2 and FFP3 dust mask from manufacturers?

To ensure you are purchasing genuine, CE-certified FFP2 or FFP3 masks, it is important to source them from reliable and traceable suppliers. Look for suppliers that provide:

Verified CE certificates showing compliance with EU PPE Regulation (EU) 2016/425.

Notified Body (NB) test reports, confirming the masks have passed EN 149 filtration, leakage, and performance tests.

Traceable batch or lot numbers, allowing quality verification and recall tracking if needed.

Clear manufacturer details, including name, logo, and contact information.

Compliance with EN 149:2001+A1:2009, ensuring consistent filtration, leakage control, and breathing resistance standards.

Purchasing directly from authorized manufacturers or official distributors helps guarantee consistent quality and minimizes the risk of counterfeit or substandard masks. Always cross-check Notified Body numbers and certificates on the EU NANDO database to confirm authenticity before buying.

FFP1 / FFP2 / FFP3 From Trusted Dust Mask Manufacturer

This section highlights our complete series of FFP1, FFP2, and FFP3 dust masks, all engineered and manufactured in our own fully certified production facility. As a reliable disposable face mask manufacturer, we oversee every stage of the process — from raw material selection and melt-blown filtration testing to precision molding and final quality inspection — to ensure full compliance with EN 149:2001+A1:2009 performance requirements. Browse our product range to review filtration efficiency, fit design, breathability, and comfort upgrades, and find the most suitable respirator solution for industrial safety, workplace dust protection, or healthcare applications.

Contact Us