No one expects an arc flash, but when it happens, the right Arc Flash PPE can save your life. Whether you’re an electrician, engineer, or safety officer, knowing the NFPA 70E Arc Flash PPE Requirements can make all the difference in preventing injury and staying OSHA compliant.

What Is an Arc Flash?

An arc flash is a sudden, powerful electrical explosion. It happens when energy is released without control from an electrical fault. When electricity jumps through the air from one conductor to another, it creates intense heat, light, and pressure. This can happen from equipment failure or accidental contact. This combination can cause serious fires, violent blasts, and deadly injuries in an instant, making arc flash PPE critical for worker safety.

Common Causes of Arc Flash Events

From my experience, arc flashes happen for several reasons, including:

– Someone accidentally touches an energized part and a grounded surface

– Equipment breaks down or parts get old

– Using tools without insulation or the wrong instruments near live parts

– Working on cables that are damaged or have exposed live wires

– Electrical connections are loose, or parts are left exposed

– Employees lack proper training or awareness of their surroundings

– Things in the environment like dust, moisture, or rust

These issues can turn a simple job like maintenance or testing into a very dangerous situation without any warning.

What Kind of Injuries Can an Arc Flash Cause?

Arc flash temperatures can reach up to 35,000°F (19,427°C), which is hotter than the sun’s surface. In my opinion, understanding the potential harm is key. These conditions can lead to:

| Type of Injury | Description |

|---|---|

| Severe third-degree burns | Arc flash temperatures up to 35,000°F (19,427°C) can cause life-threatening burns |

| Clothing catching fire or melting | High heat can ignite or melt clothing, increasing danger to workers |

| Splashed liquid metal and flying debris | Molten metal and sharp objects can injure skin and eyes |

| Pressure waves from the blast | Strong enough to burst eardrums and cause hearing loss |

| Bright light flashes | Intense flashes can cause permanent vision damage |

The blast’s force can also throw debris or even a worker across a room, adding to the danger, which is why Arc Flash PPE is essential.

What Makes an Arc Flash More or Less Severe?

| Factor | Description |

|---|---|

| Voltage level | Both high and low-voltage systems can create dangerous arc flashes. Never underestimate lower voltage systems. |

| Available fault current | A higher electrical current releases more energy, which means greater harm. |

| Clearing time | The time it takes for a safety device to stop the arc. A longer time allows more energy to build up. |

| Electrode setup | The distance and positioning of conductors can change the arc’s strength and direction. |

| Worker’s distance | Standing closer to the event increases the risk and severity of injury. |

| Enclosure size | A small, enclosed space intensifies the blast pressure and increases the chance of injury. |

Understanding NFPA 70E: Background, Scope, and What’s New in 2024

Scope and Applicability:

-

Applies to electrical workers in manufacturing, construction, and facility maintenance.

-

Covers safe work practices, PPE requirements, and hazard identification.

-

Does not apply to utility workers, who follow other standards.

Major Changes in The 2024 NFPA 70E Edition

- Clearer Terms: They made the language about risk clearer. Terms like “electric shock” are now used in a standard way. The word “shock” by itself now means “shock wave” within PPE boundaries.

- More Protector Material Choices: You are no longer limited to “Leather” for protector gloves. Other advanced materials are now okay. This lets employers choose better or more cost-effective gear, which I think is a great step forward.

- Focus on Risk Assessment: I see a stronger focus on doing regular electrical risk assessments. This makes sure teams identify and control hazards before anyone is exposed to them.

- New Equipment Maintenance Guide: They added Annex S to help safety professionals assess and maintain electrical equipment. It stresses practices like inspections, testing, monitoring, and labeling.

- Emergency Plans: Employers must now have a written emergency response plan. I recommend that this plan include practice drills and cooperation with emergency services for electrical accidents.

- Tougher Audits: A full audit of the electrical safety program is now required at least every three years. This audit should cover training, PPE, risk assessment, and emergency plans.

- Updated PPE Rules: The PPE requirements received an update. They now reflect technological improvements in protective equipment.

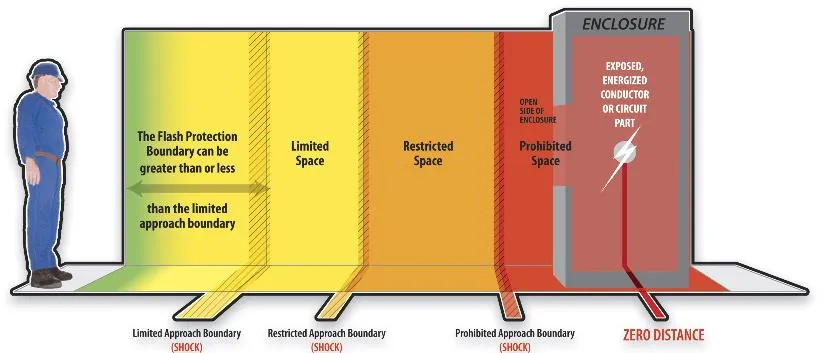

- Clearer Safety Boundaries: The definitions for safe approach distances are simpler. This makes it easier for workers and managers to understand the safe distance from energized equipment.

How Does NFPA 70E Work with OSHA Electrical Safety Rules?

While OSHA enforces general workplace safety laws, it does not detail specific electrical PPE requirements or work practices. In my opinion, NFPA 70E fills this gap. Its guidelines help employers meet OSHA’s electrical safety rules by providing:

– Detailed guidance for selecting PPE

– Procedures for hazard assessments and labeling

– Proven work practices to control risks

This makes NFPA 70E the accepted industry standard for practical electrical hazard control. I believe it helps businesses move beyond just basic legal requirements. You can create complete, modern safety programs using it.

Arc Flash Risk Assessment Methods

To follow NFPA 70E rules for arc flash safety gear, I believe choosing the right assessment method is crucial. The standard offers two main ways to do this. You can use the Incident Energy Analysis Method or the PPE Category Table Method. From my perspective, knowing how each one works helps you pick the right gear. This practice keeps workers safe and makes sure you meet all safety regulations.

|

Topic

|

Details

|

|---|---|

|

Assessment Methods

|

Two methods:

Incident Energy Analysis and PPE Category Table

|

|

Incident Energy Analysis Method

|

– Calculates arc flash energy (cal/cm²) at a specific work distance.

– Uses fault current, voltage, clearing time, and equipment setup.

– 1.2 cal/cm² is the baseline for second-degree burns.

– PPE must have a higher arc rating than calculated energy (e.g., 7 cal/cm² needs ≥8 cal/cm², Category 2).

– Requires software and equipment data for accuracy.

– Provides specific PPE rules for each piece of equipment based on real-world hazards.

|

|

PPE Category Table Method

|

– Uses tables (e.g., Table 130.7(C)(9)(a)) to assign PPE based on tasks.

– Categories and minimum arc ratings:

– Category 1: 4 cal/cm²

– Category 2: 8 cal/cm²

– Category 3: 25 cal/cm²

– Category 4: 40 cal/cm²

– No full energy calculation needed for listed tasks/equipment.

– Useful for routine maintenance, but may not apply to non-standard setups.

– Risk of over- or under-protection if conditions differ from table assumptions.

– Recommended to use Incident Energy Analysis for non-standard jobs.

|

|

Arc Flash Boundary

|

– Closest safe distance from live equipment to avoid second-degree burns (energy >1.2 cal/cm²).

– Must be marked with signs showing energy level or PPE category.

– Defines safe work zones and when full PPE is required.

|

|

Assessment Frequency & Documentation

|

– Conduct assessments every 5 years or after major system/equipment changes.

– Document all assessments, including the method used and results, for reference and compliance.

|

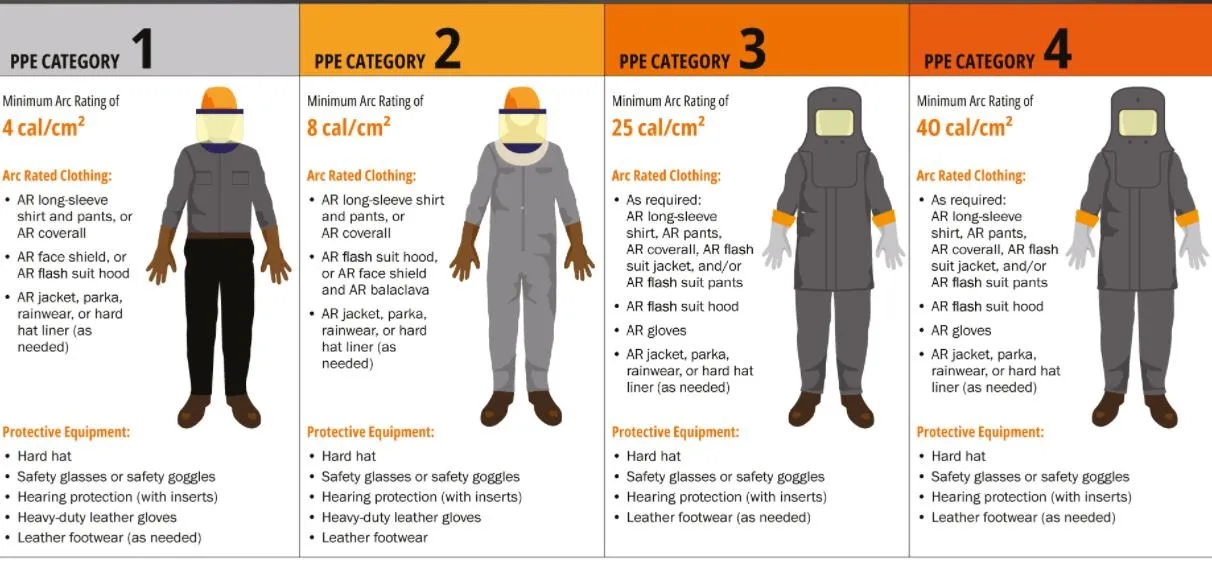

NFPA 70E Arc Flash PPE Requirements Chart

From my perspective, Arc-rated (AR) clothing is essential for electrical safety because it provides critical protection against the intense thermal energy released during an arc flash. Unlike general flame-resistant clothing, AR gear is specifically designed and tested to withstand arc flash conditions, offering a reliable barrier between the hazardous energy and the body. This aligns with the NFPA 70E Arc Flash PPE Requirements Chart, which mandates the use of appropriate personal protective equipment to safeguard workers from arc flash incidents.

PPE Categories and What to Wear

NFPA 70E groups arc flash PPE into four categories. Each has a minimum protection level, or Arc Thermal Performance Value (ATPV). We measure this in calories per square centimeter (cal/cm²).

| PPE Category | Min. Arc Rating (cal/cm²) | What Clothing to Wear | What Protective Gear to Use |

|---|---|---|---|

| 1 | 4 | AR long-sleeve shirt and pants or coveralls | Hard hat, safety glasses/goggles, hearing protection, leather gloves, leather footwear |

| 2 | 8 | AR shirt and pants or coveralls, AR face shield/hood | Hard hat, safety glasses/goggles, hearing protection, leather gloves, leather footwear |

| 3 | 25 | AR flash suit (jacket, pants, hood), AR gloves | Hard hat, safety glasses/goggles, hearing protection, leather footwear, integrated flash suit hood |

| 4 | 40 | AR flash suit (jacket, pants, hood), AR gloves | Hard hat, safety glasses/goggles, hearing protection, leather footwear, complete integrated flash hood |

What PPE to Use for Each Body Part

- Head and Face:

For PPE Categories 1 and 2, a hard hat is required. I suggest that for Categories 2 through 4, you must use a face shield or arc flash hood that protects the face, forehead, ears, and neck. Categories 3 and 4 require a complete hood system for total head safety. - Hands:

Leather gloves work for Categories 1 and 2. For Categories 3 and 4, workers need to use arc-rated, rubber-insulated gloves with leather protectors over them. - Feet:

You must wear leather footwear for all categories. This applies no matter the arc rating.

Important Notes and Examples

- Below 1.2 cal/cm²:

I find that you usually don’t need arc flash PPE for energies under 1.2 cal/cm² at 18 inches. This is not a common situation in industrial jobs. - Extra PPE:

You may need AR jackets, rainwear, and lined hard hats. This depends on your work environment. - Face Protection:

I suggest making sure face shields wrap around to protect the face, ears, and neck, not just the front. - Layering:

A single AR layer is enough for Categories 1 and 2. For Categories 3 and 4, you need multiple layers for better protection. - Example Task:

Imagine you’re servicing a 480V panel that has an incident energy of 10 cal/cm². You must wear Category 2 PPE. This means an AR shirt and pants or coveralls, an AR face shield or hood with a balaclava, a hard hat, safety glasses, hearing protection, leather gloves, and leather footwear. - How to Choose PPE:

NFPA 70E allows you to choose PPE in two ways. You can use a calculated energy analysis or the category table. I believe whichever you choose, you must document it well and use the method consistently.

This guide should help you match the right PPE level to the task and hazard. Following these points helps you stick to the best safety practices and rules.

Important Tips for Arc Flash PPE: Layers, Hearing, DC Power, and Clothing Care

When you select and use arc flash PPE, it’s important to follow NFPA 70E. From my experience, people often miss a few key details. I want to point out some things that directly affect your safety and compliance.

|

Topic

|

Details

|

|---|---|

|

Non-Melting Underlayers & Layering

|

– Use non-melting, natural fibers (cotton, wool, silk) for underlayers to avoid burns from melting synthetics (e.g., polyester, nylon).

– Recommended setup for high-risk tasks (Categories 3–4): cotton t-shirt under arc-rated (AR) shirt or coverall.

– Layering adds protection and meets strict arc ratings for hazardous jobs.

|

|

Hearing Protection

|

– Required inside arc flash boundary due to blast noise (>140 dB), which can cause permanent hearing loss.

– Use ear canal inserts or earplugs when incident energy exceeds the action threshold.

|

|

PPE for DC Systems (150–600 VDC)

|

– DC arcs can last longer, increasing burn risk.

– PPE must match measured incident energy, even at lower voltages.

– Required: AR long-sleeve shirts, pants or coveralls, AR face shields/hoods, insulated rubber gloves with leather protectors.

|

|

Caring for Arc-Rated Clothing

|

– Follow ASTM F1449 standards: wash per manufacturer instructions, avoid bleach, fabric softeners, or high-heat drying.

– Inspect regularly for damage, dirt, or wear; repair with approved materials or retire damaged items.

– Store away from sunlight, heat, or chemicals.

– Log all cleaning and maintenance checks as part of the safety plan.

|

NFPA 70E Arc Flash Training and Employer Compliance

In my experience, staying safe from arc flash hazards is about more than just wearing the right protective gear. NFPA 70E provides clear rules for training and what employers must do. I believe following these requirements is the best way to ensure electrical safety and prevent injuries at work.

Arc Flash Safety Training: Who Needs It and How Often

I suggest that arc flash training should be required for all workers, both qualified and unqualified. Qualified workers must learn how to identify electrical dangers and use PPE the right way. They also need to master safe work methods and be able to spot and stay away from dangerous situations. Unqualified workers just need awareness training so they can see hazards and avoid them.

- I recommend retraining everyone at least every 3 years. You must retrain people sooner if they change jobs or you get new equipment. If a safety inspection shows any problems, you need to retrain immediately.

- Big changes, like a new arc flash study or adding machinery, also mean it is time for fresh training for all workers involved.

Documentation, Verification, and Recordkeeping

You must document and verify every training session. I suggest employers keep organized records that include:

– Employee names

– Training dates

– Topics or content covered

– Certificates of completion. I think it is a good practice to give these to workers after each course as their formal proof.

These records are essential for any audits and for staying on the right side of the law.

Employer Responsibilities Under NFPA 70E

From my perspective, employers have significant duties for arc flash safety:

– Provide all necessary PPE. The type of PPE should be based on a current arc flash risk assessment.

– Enforce the use of PPE and safe work habits on every single job.

– Make sure electrical equipment has correct labels and all safety procedures are current.

– I advise you to review, update, and retrain employees often to match new standards or changes at the workplace.

– If you don’t document training or enforce the safety rules, you can get citations and fines from OSHA. This happens because arc flash is a known workplace hazard.

Who Needs NFPA 70E Arc Flash Training?

I believe many different jobs and professions require this type of safety training. Some examples include:

– Electrical engineers and contractors

– Inspectors

– HVAC installers

– Safety managers

– System designers

If you work anywhere near energized equipment, you need this training. Your specific job title does not create an exemption.

The Real-World Importance of Compliance

Arc flash events continue to be a serious threat in the workplace. In 2020, direct exposure to electricity caused about 56% of reported injuries. This statistic, from my point of view, shows why complete training and strictly following PPE rules are so critical.

NFPA 70E Arc Flash Labeling: What I Put on Every Label

Based on my experience, arc flash labels are vital for electrical safety. They help workers instantly see the risks and what Personal Protective Equipment (PPE) they need to wear.

The NFPA 70E 2024 standard is clear. Any electrical equipment that might be worked on while live needs a proper arc flash label. This applies to hardware like switchboards, panelboards, industrial control panels, meter sockets, and motor control centers.

What I Ensure is on Every Arc Flash Label

I make sure every arc flash label shows this information:

– Nominal system voltage

– Arc flash boundary (the distance where a worker could get a second-degree burn)

– One of the following data points:

– The available incident energy and working distance

– The minimum arc rating for clothing

– The Arc Flash PPE Category from Table 130.7(C)(15)(a) or (b), but not both

– A site-specific PPE level

Explaining the Key Parts

- Arc Flash Boundary: This marks the closest safe distance to the equipment. It can be anywhere from 18 inches to several feet. The distance depends on the potential energy release.

- Incident Energy: This is shown in cal/cm². I use this value to pick the right PPE. I’ve seen it range from 1.2 cal/cm², enough for a bad burn, to over 40 cal/cm² for the most hazardous gear.

- PPE Category: This tells workers what protection level they need:

- Category 1: Arc-rated clothing of at least 4 cal/cm²

- Category 2: Minimum 8 cal/cm²

- Category 3: Minimum 25 cal/cm²

- Category 4: Minimum 40 cal/cm²

Label Design and Durability Tips

- I recommend using visible “Danger” or “Warning” headers on your labels.

- “Danger” is for the greatest risks. I use this for incident energy above 8 cal/cm² or for life-threatening hazards.

- “Warning” is for lower risks. You should follow the color and language formats in ANSI Z535.2 and Z535.4.

- Labels must be durable and easy to read in their specific environment. I suggest you do not use handwritten labels. The only time I’d consider one is for temporary use if the information changes often.

My Schedule for Updating Arc Flash Labels

I make sure to update arc flash labels at these times:

– Whenever equipment is changed

– After a system upgrade

– If protective device settings are adjusted

– After each arc flash risk reassessment

If you fail to update labels, you put workers at risk. They will have outdated information about the danger.

Example Arc Flash Labels

- Switchboard

- Nominal voltage: 480 V

- Incident energy: 8.2 cal/cm² at 18 inches

- Arc flash boundary: 32 inches

- PPE category: 2

- Header: DANGER

- Panelboard

- Nominal voltage: 208 V

- Incident energy: 2.5 cal/cm²

- Arc flash boundary: 24 inches

- PPE category: 1

- Header: WARNING

Reference Standards to Know

For label rules, I always go back to NFPA 70E Section 130.5(H). For durability, I check NEC 110.21(B). I should also mention that some supervised industrial sites have exceptions. This applies if their hazard information is documented and easy for qualified people to access.

Following these labeling rules puts vital safety information right where it’s needed. I believe this is the best way to prevent injuries and promote safe work practices.

Best Practices for Arc Flash Safety: My Advice on Studies, Risk Controls, and Compliance

To build a strong arc flash safety program, I suggest following some key practices. This thinking goes beyond just wearing PPE. It helps create long-term protection for anyone working near electrical dangers.

The Importance of Regular Arc Flash Studies

- I find that regular arc flash studies are vital for finding and understanding potential dangers.

- NFPA 70E suggests using engineering analysis instead of just using table values. From my experience, this gives you more precise arc flash boundaries. It also helps you pick the correct PPE for each job.

- For example, a good study finds the arc flash boundary where incident energy hits 1.2 cal/cm². This keeps your workers safe and meets legal rules.

- These studies require technical skills. I suggest working with experienced engineers or consultants. This is the best way to get accurate results and stay compliant with the law.

Applying the Hierarchy of Risk Controls

- I always recommend starting by removing hazards where you can. This could mean designing out a risk or taking away a source of electrical exposure.

- If you cannot remove a hazard, the next step is substitution. This involves using safer equipment or work methods.

- Engineering controls are next on my list. These include installing barriers or automatic shut-offs.

- After that, I use administrative controls. These are things like strict safety procedures and lockout/tagout routines.

- I view PPE as the last line of defense. Use it only after you have applied all other safety controls.

Working With Safety Consultants

- In my experience, working with safety consultants makes a real difference. They can:

- Find hidden dangers you might overlook.

- Perform detailed risk assessments.

- Create safety plans that are practical and work well.

- Deliver full training programs that mix classroom learning with hands-on exercises.

- Consultants follow the latest NFPA 70E and OSHA rules, so your safety program will stay current.

Keeping Up With NFPA 70E and OSHA Revisions

- Both NFPA 70E and OSHA update their electrical safety standards from time to time.

- These updates can add new rules for how often you assess hazards, maintain PPE, or label equipment.

- I recommend you review your safety protocols every time the standards are revised. Comparing them to the new version helps you find anything that is outdated.

- If you are not sure if a change applies to your workplace, I suggest you ask a safety consultant or your local authority for help.

Additional Tips for Managing Arc Flash Risk

- My advice is to conduct risk assessments and arc flash studies at least every five years. You should do them sooner if you change your equipment or processes.

- I think all equipment needs clear, up-to-date arc flash labels. These must show the current incident energy, arc flash boundaries, and the PPE categories required.

- You should train your workers often so they learn how to spot hazards and use their PPE correctly.

- I also recommend you document every risk assessment, training session, and safety rule update. You will need these records for future audits or inspections.

By doing regular studies, using solid risk control methods, getting expert help, and following standard updates, you will do a much better job of keeping your team safe and your facility compliant.