Safety is important, no matter where you work or what you do. Whether you’re in construction, healthcare, or a lab, having the right protection can truly save your life. But how do you know exactly what kind of gear you need? What are the levels of full body PPE—and which one is right for your specific job? Let’s break it down clearly and simply.

What Are The Levels Of Full Body PPE?

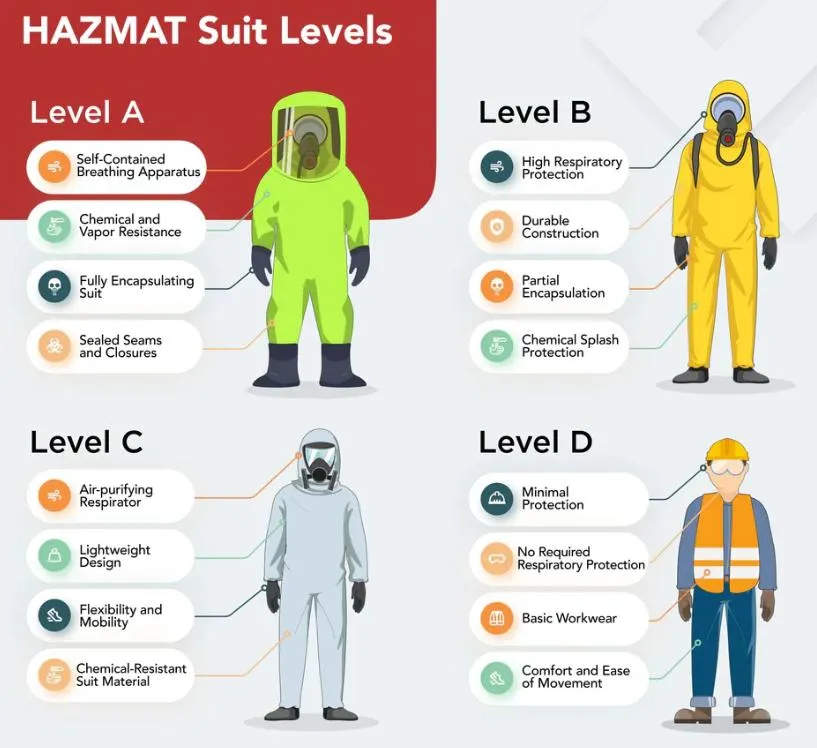

Full body PPE is categorized into four levels—Level A, Level B, Level C, and Level D—each designed to address specific hazards in hazardous work environments. Selecting the appropriate PPE level is critical for ensuring worker safety and compliance with regulations, such as those set by OSHA. Below, I outline each level, including its components, applications, and considerations, based on practical experience and safety standards.

Level A Full Body PPE: Maximum Protection for Extreme Hazards

Description: Level A Full Body PPE provides the highest level of protection for skin, respiratory systems, and eyes. It is designed for environments with life-threatening vapors, gases, or highly toxic substances that pose significant risks through inhalation or skin contact.

When to Use: I recommend Level A Full Body PPE in situations involving unknown hazards, highly toxic chemicals that can vaporize, or a high risk of chemical splashes or immersion. It’s essential for scenarios where exposure could result in severe injury or death.

Components:

- Positive-Pressure, Full Face-Piece SCBA: A NIOSH-approved self-contained breathing apparatus (SCBA) ensures safe breathing by supplying clean air under positive pressure.

- Totally Encapsulating Chemical-Protective (TECP) Suit: A vapor- and gas-tight suit fully seals the wearer from the environment, often referred to as a “moon suit” due to its sealed design with special exhalation valves and seams.

- Inner and Outer Chemical-Resistant Gloves: Dual layers of chemical-resistant gloves provide enhanced protection against hazardous substances.

- Chemical-Resistant Steel Toe and Shank Boots: These protect feet from chemical exposure and physical injuries, worn either over or under the suit, depending on its design.

- Hard Hat or Helmet: Worn under the suit for additional impact protection.

- Optional Gear: Coveralls, long underwear, or disposable suits, gloves, and boots can be added for extra protection.

Applications: Level A Full Body PPE is critical for hazardous material (hazmat) response teams dealing with chemical spills, toxic gas leaks, or unidentified substances. It’s also used in confined spaces or environments with high ammonia levels or other toxic vapors.

Price Range: A Level A suit typically costs between $1,500 and $3,000 or more, depending on the brand and features.

Guidance: Level A is non-negotiable for workers entering areas with extreme chemical dangers, particularly where the risk to life or health is high. Regular training, fit testing, and maintenance are essential to ensure the gear performs effectively.

Level B Full Body PPE: High Respiratory Protection with Moderate Skin Defense

Description: Level B Full Body PPE offers robust respiratory protection, similar to Level A, but provides less skin protection. It is suitable for environments with significant airborne hazards but lower risks of skin exposure to vapors or gases.

When to Use: I advise using Level B Full Body PPE when maximum respiratory protection is needed, but the risk of skin absorption is minimal. It’s ideal for situations where liquid splashes are a concern, but vapor-tight suits are unnecessary.

Components:

- Positive-Pressure Full Face-Piece SCBA: A NIOSH-certified SCBA or a supplied-air respirator with an escape SCBA ensures safe breathing.

- Hooded Chemical-Resistant Clothing: Includes non-encapsulating suits, such as one-piece coveralls or two-piece splash suits, offering protection against liquid splashes but not vapors or gases.

- Chemical-Resistant Gloves and Boots: Dual-layer gloves and steel-toed, chemical-resistant boots provide hand and foot protection.

- Hard Hat: Often worn under the hood for added impact resistance.

Applications: Level B Full Body PPE is commonly used by emergency responders during initial site entries or chemical spill responses where airborne hazards are present, but skin contact risks are lower. It’s also used in hazardous waste operations before a full hazard assessment.

Price Range: Level B suits typically range from $800 to $2,000.

Protection and Limitations:

- Respiratory Protection: Matches Level A with SCBA for maximum safety against airborne contaminants.

- Skin Protection: Protects against liquid splashes but not vapors or gases, as the suit is not vapor-tight.

- Limitations: Unsuitable for environments with high skin-absorption risks or where complete vapor protection is required. Regular training and fit testing are critical for effectiveness.

Guidance: Level B strikes a balance between strong respiratory protection and moderate skin coverage, making it versatile for high-risk environments without the encumbrance of a fully encapsulating suit. OSHA regulations mandate ongoing training and maintenance for compliance.

Level C Full Body PPE: Air-Purifying Respirators with Basic Chemical Protection

Description: Level C Full Body PPE is appropriate when airborne hazards are known, measurable, and can be effectively filtered by air-purifying respirators (APRs). It provides moderate protection for both respiratory and skin hazards, balancing safety and comfort.

When to Use: Use Level C Full Body PPE when the concentration of airborne contaminants is below immediately dangerous to life or health (IDLH) levels, and an APR can adequately filter the hazards. It’s suitable for environments with low to moderate risks of skin or eye exposure.

Components:

- Air-Purifying Respirator (APR): Full-face or half-mask respirators equipped with appropriate cartridges or canisters for specific contaminants.

- Hooded Chemical-Resistant Clothing: Coveralls or two-piece splash suits protect against liquid splashes.

- Chemical-Resistant Gloves: Inner and outer gloves enhance hand protection.

- Steel-Toed, Chemical-Resistant Boots and Boot Covers: Protect feet from chemical exposure and physical injuries.

- Additional Accessories: May include hard hats, face shields, escape masks, or two-way radios for communication.

Applications: Level C is widely used in laboratories, hazardous waste cleanup, and emergency response scenarios where air monitoring confirms manageable hazards. It’s also common in healthcare settings dealing with pathogens.

Price Range: A complete Level C set typically costs $400 to $1,200, depending on quality and additional features.

Guidance: Level C is a practical, cost-effective option for environments with identified and controlled hazards. However, it requires thorough risk assessments to confirm that APRs provide sufficient protection. Regular training, fit testing, and equipment maintenance are essential to ensure safety.

Level D Full Body PPE: Minimal Protection for Low-Risk Environments

Description: Level D Full Body PPE offers the least protection, functioning as a standard work uniform rather than specialized safety gear. It is designed for environments with no significant respiratory or skin hazards.

When to Use: I recommend Level D only in workplaces confirmed to be free of respiratory hazards and significant skin exposure risks. It’s suitable for general tasks with minimal contamination.

Components:

- Standard Work Uniform: Typically, coveralls or similar attire for basic body coverage.

- Gloves: Provide basic hand protection.

- Safety Boots or Shoes: Steel-toed, chemical-resistant footwear.

- Safety Glasses or Goggles: Protect eyes from minor hazards.

- Optional Gear: Hard hats, face shields, or disposable boot covers may be added as needed.

Applications: Level D is appropriate for general site work, such as in warehouses or maintenance tasks, where hazardous materials are absent.

Price Range: Costs are typically under $100 per set.

Guidance: Level D should never be used in environments with respiratory or significant skin hazards, as it lacks advanced protective features. It’s ideal for low-risk settings but requires a thorough hazard assessment to confirm its suitability.

Core Summary Table: Levels of Full Body PPE

| Full Body PPE Level |

Respiratory Risk | Skin Risk | Typical Equipment Components | Description & Examples |

| Level A | High | High | – Self-contained breathing apparatus (SCBA) | This level offers the highest protection from chemicals and gases. I think of TECP suits as “moon suits” because they are vapor and gas-tight. They have special exhalation valves and seams. I would use these in the most dangerous situations, like hazardous materials responses or chemical spills. |

| – Totally-encapsulating chemical-protective (TECP) suit | ||||

| – Chemical-resistant gloves (inner/outer) | ||||

| – Boot covers | ||||

| Level B | High | Moderate | – SCBA or supplied air respirator | This gives strong breathing protection but less skin protection than Level A. These suits are not vapor-tight. I recommend using them when there’s a high risk of breathing in harmful substances, but the skin contact risk is lower. |

| – Non-encapsulating chemical-protective suit | ||||

| – Chemical-resistant gloves and boots | ||||

| Level C | Moderate | Moderate | – Air-purifying respirator (APR) | I use this level when the hazards are known and not too severe. Both breathing and skin exposure risks are moderate. It’s for situations with specific contaminants and plenty of oxygen, like in laboratory work or in healthcare when dealing with pathogens. |

| – Chemical-resistant clothing (coveralls, splash suits) | ||||

| – Gloves, boots | ||||

| Level D | Low/None | Low/None | – Standard work uniform | This offers very basic protection. I use it for minor “nuisance” contamination. No breathing protection is needed. I find it suitable for areas free of specific hazards beyond standard PPE needs, like warehouses or general industry jobs. |

| – Gloves, safety eyewear, and hard hats as needed |

Key Equipment Features Across Full Body PPE Levels

- Totally-Encapsulating Chemical-Protective (TECP) Suits: These suits give you complete, sealed body coverage. I recommend them for handling unknown hazards or very toxic substances. These suits are gas-tight. They also feature integrated face shields, exhalation valves, and special seams.

- Non-Encapsulating Chemical-Protective Suits: These suits provide good protection from splashes and liquid chemicals, but they aren’t vapor or gas-tight. I find they are suitable for environments with moderate skin hazards.

- Respiratory Protection:

- Level A & B: SCBA offers the most secure breathing protection.

- Level C: I use Air-Purifying Respirators (APR) for hazards that you can identify and measure.

- Hand Protection:

- I recommend using specialized gloves. For example, leather gloves are for sparks and heat. Aluminized gloves provide reflection and insulation. Aramid gloves protect against cuts and abrasions. Synthetic gloves are for chemicals, but be aware that they have limitations against certain solvents.

- I recommend layering, using inner and outer gloves, at higher PPE levels for more defense.

- Boot and Foot Protection:

- I suggest boots with chemical resistance. Many of these also have steel toes and shank protection.

- I find that disposable over-boots offer extra coverage in areas with high contamination.

- Additional Protective Clothing: I sometimes use aprons, disposable coveralls, and layering. This depends on the hazard’s severity and the specific tasks.

Regulatory Guidelines and Best Practices

- OSHA & CDC Guidance: These agencies stress that your Full Body PPE must match the risk level. I believe following the correct steps for putting on (donning) and taking off (doffing) PPE is vital to stop contamination.

- Relevant Standards:

- OSHA 29 CFR 1910.135 for head protection requirements.

- 29 CFR 1910.137 for electrical glove protection.

- Layered Protection: I recommend adjusting PPE setups by adding items like aprons, face shields, or disposable outer layers. This helps with specific issues such as chemical splashes, sparks, or abrasion.

Real-World Examples and Typical Scenarios

- Level A: Hazmat teams use this level in toxic release situations or incidents with unknown substances.

- Level B: People choose this for initial site entry if there’s a high vapor or gas risk, but skin hazards are low.

- Level C: I find this level appropriate for decontamination lines. It’s also good for laboratory work with known hazardous substances, or for cleanup tasks where you know the risks.

- Level D: This level is enough for standard site tasks that don’t involve serious contaminants. I believe it is ideal for maintenance work or warehouse operations.

Key Factors I Consider When Choosing Full Body PPE

When I help select full body PPE, it’s not just about grabbing the gear with the highest protection rating. From my experience, it’s crucial to match the equipment to the actual dangers present in the workplace. This approach ensures every worker stays safe, feels comfortable, and can do their job well. Here’s what I always prioritize:

1. My First Step: Check All Workplace Dangers Carefully

- I start by identifying all specific dangers. These could be chemicals, electrical risks, radiation, or other threats present at your job site.

- Then, I perform a full risk assessment to figure out what type of protection is needed.

- I make sure to understand how workers might come into contact with chemicals (like a splash or full immersion) and for how long they might be exposed.

- I’ve learned that there isn’t one solution for everyone. You need to customize your PPE strategy to the real risks involved.

2. How Well the Gear Works for the Job

- I recommend choosing Full Body PPE that directly addresses the tasks your team performs and the hazards they face.

- For example, I check if gloves are right for the job. Do you need a good grip in oily or wet conditions?

- If your team works in hot or cold spots, I suggest looking for gear that offers thermal protection.

- I also advise selecting safety eyewear with anti-fog coatings if your specific work environment calls for it.

3. Comfort, Fit, and Ease of Movement

- In my view, gear must be comfortable. If it’s not, people might not wear it the right way, or at all.

- I suggest looking for designs that allow the skin to breathe, are easy to move in, and have adjustable features. This is very important for people working long shifts.

- I always make sure the sizing is accurate for every team member. I also check that different pieces of PPE can be worn together without causing problems.

- A poor fit can leave workers exposed. I always double-check that the gear provides good coverage and allows for clear vision and easy movement.

4. I Verify Compliance and Certifications

- I make sure all Full Body PPE meets OSHA regulations and has been appropriately tested by reputable labs.

- I recommend following ANSI/ISEA standards as they provide good benchmarks for safety and performance.

- For respirators, I always verify NIOSH certification. This is particularly key for SCBA, APR, and other similar breathing apparatus.

5. How Long Does It Last and How to Care for It

- Durable equipment, in my opinion, really pays off. High-quality full body PPE that you can clean easily means less work stoppage and fewer replacements.

- Maintenance is also important. I find that regular checks and cleaning keep Full Body PPE working at its best and protect your investment.

6. Getting Good Value in the Long Run

- I advise looking beyond the initial purchase price. It’s better to add up the long-term value. This includes fewer injuries, lower replacement costs, and less downtime.

- From my experience, training and support from the vendor (like help with fit testing or managing your inventory) can make a big difference to the overall value.

7. Thinking About the Work Area and Job Details

- I always consider factors like workplace temperature, humidity levels, the presence of dirt, and the overall climate.

- I check to ensure the equipment protects all necessary body areas. For instance, some tasks might only need gloves that cover the hand, while others might require gloves that protect the entire arm.

- Gear needs can change with different job tasks. I find that adaptable equipment helps meet every requirement effectively.

So, in my opinion, when you carefully balance all these factors—the type of hazard, worker comfort, proper fit, durability, compliance, and long-term cost—you significantly boost safety and productivity. This approach also helps you avoid unnecessary risks and expenses.