What Is Non-Woven Fabric? How It's Made, Types & Benefits

Morntrip provides safe, comfortable, and affordable solutions for medical and daily hygiene needs. Our products are made from soft and reliable materials, perfect for single-use protection. We supply protective clothing, surgical and isolation gowns, face masks, disposable caps, lab coats, shoe covers, underwear, and bed sheets. These items are designed to be breathable, skin-friendly, and suitable for high-risk environments. Custom options in weight and texture are available. With efficient production and recyclable choices, we offer high-quality protection for hospitals, clinics, and distributors at low cost. Trust Morntrip for products that keep people and places safe.

What Is Non-Woven Fabric and Its Benefits

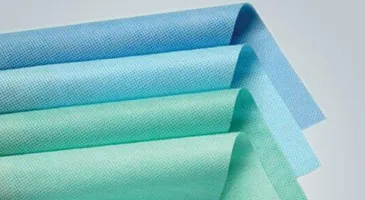

Non-woven fabric, also called non-woven cloth, is a modern material made from fibers such as polypropylene (PP), polyester (PET), nylon, viscose, acrylic, HDPE, or PVC. Usually, one type of fiber is chosen to make the fabric, depending on the purpose. Unlike woven or knitted fabrics, nonwoven fabric is made by joining fibers directly instead of turning them into yarn first. The fibers are fixed together through methods like spunbond, meltblown, needlepunch, spunlace, or heat bonding.

Characteristics of Non-Woven Fabrics

-

Soft and Airy – The fabric feels light and comfortable, which makes it gentle on the skin and suitable for long-time medical or hygiene use.

-

Strong and Reliable – It does not shed fibers, so it is safe and clean for making disposable protective clothing.

-

Low-Cost Production – The process is simple and fast, which keeps the price affordable for hospitals, clinics, and daily products.

-

Cotton-Like Feel – It has a smooth and skin-friendly texture, giving extra comfort when used in masks, gowns, and bed sheets.

How Non-Woven Fabric is Made: Types & Processes

Non-woven fabric is a strong, soft material made by joining fibers without weaving. It’s affordable and easy to produce, with different types offering special features like softness or strength. Each type of non woven fabric uses a unique method to create a web of fibers, perfect for healthcare and other needs. Learn about the main types of non woven fabric below to understand their manufacturing processes and why they suit your business.

PP Spunbond Non-woven Fabric

PP spunbond non-woven fabric is made by melting polypropylene plastic into a liquid. The liquid is pushed through tiny holes to form long, thin fibers. These fibers are stretched and laid onto a moving belt, forming a web. Hot rollers or air bond the fibers together, creating a strong, light, and airy nonwoven fabric. This quick process makes the fabric durable, affordable, and recyclable, with a smooth texture for many uses.

Non-woven Melt Blown Fabric

Non-woven melt-blown fabric is created by melting plastic, like polypropylene, into a liquid. The liquid is forced through very small holes, forming tiny, fine fibers. Hot air blows these fibers onto a moving belt, making a dense web. The fibers cool and stick together, producing a soft, filtering non-woven fabric. This process ensures excellent barrier properties, making the fabric light yet effective for trapping small particles.

SMS Non-woven Fabric

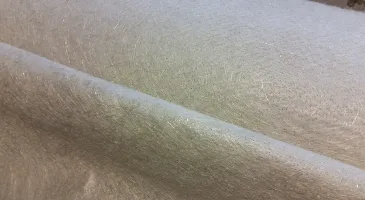

Needlepunch Non-woven Fabric

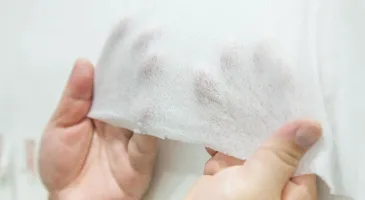

Spunlace Non-woven Fabric

Thermal-bonded Non-woven Fabric

Through-air thermal Bonded Non-woven Fabric

Airlaid Non-woven Fabric

Wet-laid Non-woven Fabric

Stitch-bonded Non-woven Fabric

Quality Testing for Non-Woven Fabric

At Morntrip, all non-woven fabric products are tested under international standards (ISO, ASTM, EN, OEKO-TEX). These six areas of testing ensure our fabric is safe, reliable, and suitable for medical and hygiene applications.

Color Fastness

Morntrip non-woven fabric is tested for resistance to washing, rubbing, water, sweat, and light. This guarantees the fabric keeps a clean and professional appearance during long-term use.

Physical Strength

Non-woven fabric is checked for tensile strength, tear resistance, seam durability, and dimensional stability. These tests ensure the fabric stays strong and keeps its shape in daily applications.

Functional Features

Morntrip non-woven fabric is evaluated for breathability, water resistance, flammability, and antistatic performance. These features make it ideal for protective gowns, face masks, and hygiene products.

Chemical & Skin Safety

We test our non-woven fabric for pH balance, formaldehyde content, and restricted substances. This guarantees the fabric is safe, skin-friendly, and compliant with REACH and OEKO-TEX standards.

Hygiene & Cleanliness

Morntrip nonwoven fabric is tested for bacterial filtration and resistance to liquid penetration. These properties ensure protection in medical-grade products such as isolation gowns and masks.

Long-Term Performance

All non woven fabric is checked for strength retention, peeling resistance, and overall stability. These tests confirm consistent quality and reliability for healthcare and industrial customers.

Morntrip Non-Woven Fabric Products

Morntrip products are designed to provide safety, comfort, and affordability for healthcare and hygiene needs. We offer protective clothing for high-risk environments, isolation gowns, surgical gowns, and face masks that ensure both protection and easy breathing. Our range also includes soft disposable underwear, clean bed sheets, non-slip shoe covers, disposable caps, and lab coats for research settings. All products can be customized in weight and texture to meet specific requirements.Quick, cost-effective production allows us to maintain low prices while ensuring high quality. Many of our items are made from recyclable materials, supporting eco-friendly practices without compromising performance. Morntrip’s nonwoven fabric products are ideal for hospitals, clinics, distributors, and labs seeking reliable, affordable protection solutions.

FAQ of Non-Woven Fabric

What are the benefits of non-woven fabric?

Is non woven fabric eco-friendly?

Can non woven fabric be customized?

Yes, non-woven fabric can be customized in weight, color, size, and thickness to meet specific healthcare needs. Made from polypropylene or polyester, it’s tailored for medical and hygiene applications, ensuring softness, sterility, and water resistance. Our ISO and CE-certified nonwoven fabric is ideal for hospitals, clinics, and distributors seeking reliable, eco-friendly solutions. Contact us for bulk, customized non woven fabric at competitive wholesale prices.

What is the difference between woven and non-woven fabric?

What sterilization methods are compatible with non-woven fabrics?

Can non-woven fabrics be custom printed or colored?

Yes, non-woven fabrics can be custom printed or colored to suit specific needs. Flexographic or screen printing adds patterns, logos, or designs for branding and visual appeal. Colors are customized by dyeing fibers like polypropylene or polyester during production. Our non-woven fabrics offer cost-effective, high-quality options for hospitals, clinics, and distributors seeking unique medical products.

What is medical non woven fabric?

Can non-woven fabric be washed?

Is non-woven fabric waterproof?

Is non-woven fabric stretchy?

Contact Us